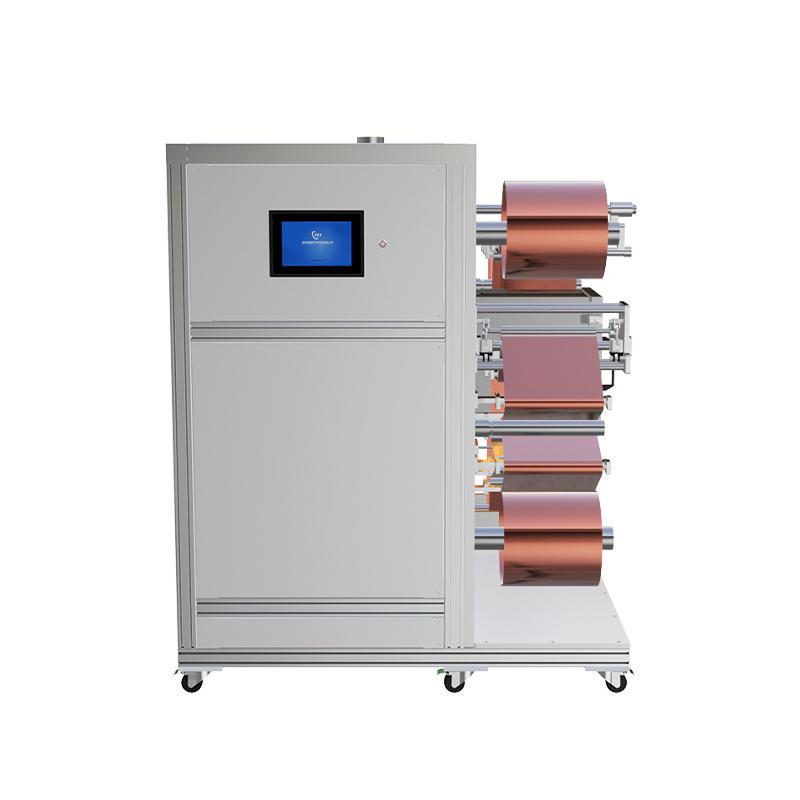

Chengyue CY-CMR-300-S Lithium battery double-sided dip coating experimental Coater Spreader

ChengYue CY-CMR-300-S Lithium battery double-sided dip coating experimental coaterSPEC

ChengYue CY-CMR-300-S Lithium battery double-sided dip coating experimental coaterDetails

ChengYue CY-CMR-300-S Lithium battery double-sided dip coating experimental coaterPacking list

- SKU

- NB048354

- Coating method

- Impregnated Spreader

- rewinding diameter

- Max:300mm

- Width of guide roller

- 300mm

- Mechanical speed

- Max:1m/min

- Spreader Accuracy

- +/- 3 μm (cathode paste, viscosity 1000CP, Solid content 35.5%, bar size 80 μm).

- Spreader Film thickness

- WFT 6-200μm (reference value, bar Spreader), depending on slurry parameters and bar type. Film thickness of cover foil can be adjusted between 0.1 m - 1mm

- Infrared drying oven heating method

- Carbon fiber infrared lamp heating

- Infrared drying oven air Volume

- Max: 402m ³/h, air valve adjustment

- Infrared drying oven temperature

- Max:150℃

- Infrared drying oven power

- 2KW

- Infrared drying oven length

- 500mm

- Correction Accuracy

- ±0.5mm

- Impregnation box comes standard

- Spreader * Small Capacity Min: 0.3L

- Impregnation box optional one

- Spreader * Small Capacity Min: 0.7L, reserved chilled down water interface

- Impregnation box optional two

- Spreader * Small Capacity Min: 2.7L, reserved chilled down water interface

- Device size

- L980mm*W750mm*H1420mm

Introduction

The double-sided dip coating experimental coater is a coating machine with an immersion coating process, and the coating can be measured with an optional wire rod. It can be rewinded and unloaded with low tension, equipped with infrared heating Drying Oven and process correction device, and optional static eliminator and impregnation box type. The equipment has simple structure, convenient operation, high production efficiency and wide range of application, and can be used in lithium-ion batteries, graphene films, ceramic films, tapes and various functional film industries.

Features

Double-sided continuous dipping.

Wire rod metering to control coating thickness and uniformity.

Infrared Drying Oven with adjustable temperature and air volume.

Stable transport for low-tension transport.

Active flattening roller guide with adjustable speed.

The peristaltic pump is automatically fed.

Equipped with deviation correction function, high transport accuracy。

- 1Operation Flow of Polymer Electrodeposition

- 2List of experimental testing instruments for research and development of nano-composite water-based barrier coatings

- 3Some theory you need to know about the dip coating process

- 4What is leveling? What parameters affect leveling?

- 5Diversity and applicability of Coating painting methods

- 6How to troubleshoot dip coating defects?

- 7How does dip coating work?

- 8Dip coating process and dip coating machine

- 9What are the requirements for preparing test samples for aqueous dip paint?

- 10Advantages and disadvantages of dip coating process and ideal use

CY-CMR-300-S

CY-CMR-300-S