HuiNuo QTZ film Conical Mandrel Bending Tester coating

HuiNuo QTZ Film Conical Mandrel Bending TesterSPEC

HuiNuo QTZ Film Conical Mandrel Bending TesterDetails

HuiNuo QTZ Film Conical Mandrel Bending TesterPacking list

- SKU

- NB048516

- Meet the standard

- ISO6860—1984(E)、ASTMD522—60(1979)、BS3900;PartE11:1985、GB/T11185

- environmental conditions

- Conditions of 23 +/- 2 ° C and (50 +/- 5) % relative temperature

- Test board size

- 100mm*180mm

- Dimensions

- 380*150*186mm

- Film thickness

- ≤0.8mm

- material

- iron

- principle

- Evaluate the cracking resistance or disbonding resistance of coatings by bending them around conical mandrel to simulate the stretching of coatings at different diameters

- function

- Used to determine the flexibility and adhesion of the film when bent on a conical mandrel.

with the scope of application

The QTZ film cone bending Tester is suitable for measuring the resistance of coatings of base coats and varnishes (including single layer and composite coating systems) to cracking or peeling off metal base plates when bent around a conical shaft under standard conditions, and can also determine the elongation of the coating.

This instrument conforms to: International Standard ISO6860-1984 (E)

American Standard ASTMD522—60 (1979)

British Standard BS3900; PartE11:1985

National standard GB/T11185

Main technical parameters:

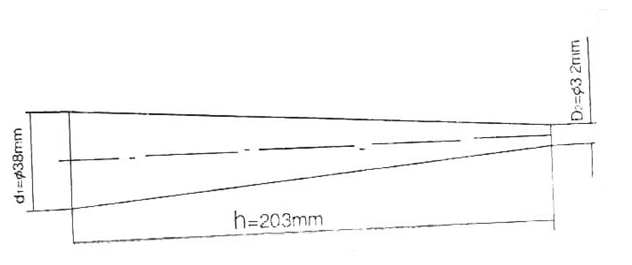

Tapered shaft size:

Principle

The instrument is purely mechanical, and its structure is mainly composed of a tapered shaft 1, a pull rod 3, a lever 6, a clamping test plate 2 and other devices.

The principle is as follows: insert the test plate between the tie rod and the tapered shaft, clamp the hand lever with a splint, turn the shaft from front to back (make the test plate bend around the tapered axis), and measure its peeling performance according to the crack position of the coating on the test plate.

Requirements for use

1. Unless otherwise required, the test should be carried out under the conditions of 23±2°C and relative temperature (50±5)%, and the instrument should be operated flat on (or fixed) on the instrument platform.

2. The sampling shall be carried out in accordance with the provisions of GB3186-82 "Sampling of Paint Products", and special samples shall be inspected and prepared according to GB1727-79 "General Preparation Method of Paint Film".

3. Test board

(1) Material and size

Unless otherwise specified or agreed, the test plate shall meet the requirements of GP9271-88 "Standard Test Plate for Color Paint and Varnish", and should be a polished steel plate, a polished tinplate plate or a soft aluminum plate.

The test plate should be flat, no deformation, the surface should not have any visible bulge or cracks, the test plate should be 100mm*180mm, its maximum thickness is 0.8mm, if there is no deformation, the test plate can be cut after coating and drying, if it is an aluminum plate, its long side should be parallel to the longitudinal (axial) in the metal rolling process.

(2) Handling and coating of test plates

Unless otherwise specified, three test plates should be prepared in accordance with the provisions of GB1727-79 "General Preparation Method for Paint Film". If the brush method is used, the brush marks should be parallel to the short side of the template.

(3) Drying and drying conditions

Dry (or bake and harden) each coated test plate at a specified time, and then place the test plate at 23±2 °C and a relative temperature of 50±5% for at least 16 hours for the deformation test as soon as possible.

(4) Coating film thickness

According to GB1764-79 "Paint Film Thickness Determination Method" to determine the thickness.

QTZ

QTZ