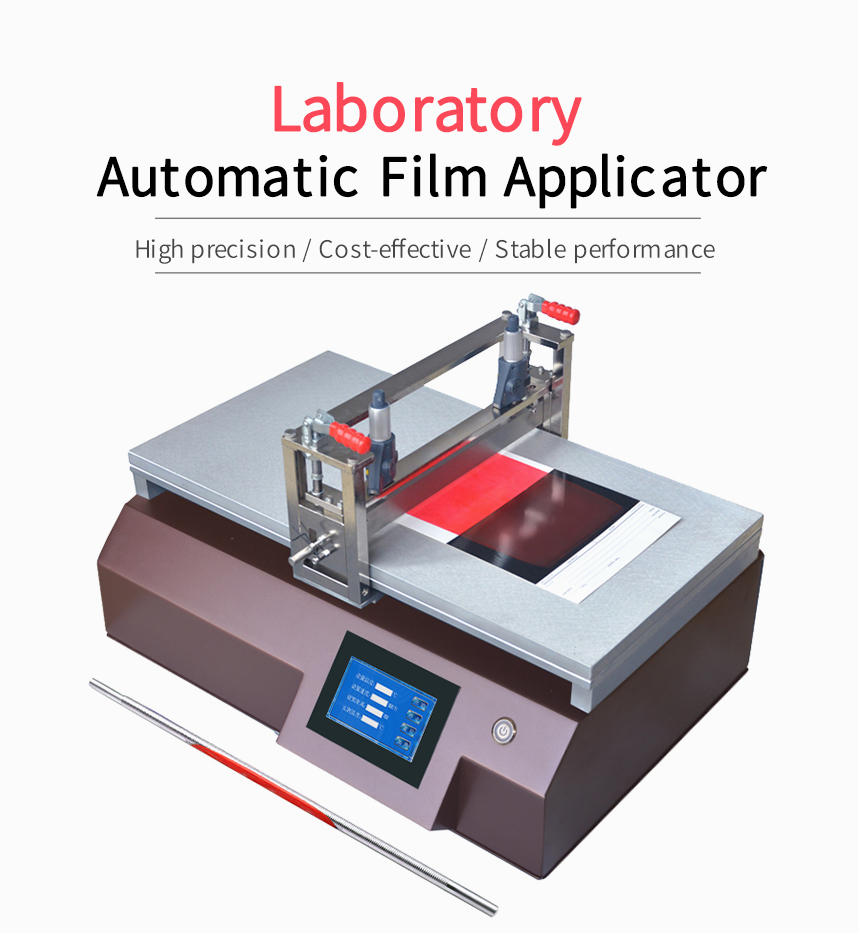

CHINA UV curing Automatic Film Applicator TBJ-X2-DJ18 Removable drawdown blade bar vacuum adsorption Coater

zy TBJ-X2-DJ18 Automatic Film ApplicatorSPEC

zy TBJ-X2-DJ18 Automatic Film ApplicatorDetails

zy TBJ-X2-DJ18 Automatic Film ApplicatorPacking list

- SKU

- NB048639

- Coating method

- Bar + drawdown blade

- Coating speed

- 5~ 200Mm/s (< 5mm/s can be customized)

- Coating size

- 300 * 400Mm (can be customized)

- Spreader speed

- Digital display, different speeds

- speed control

- Infinitely variable speed

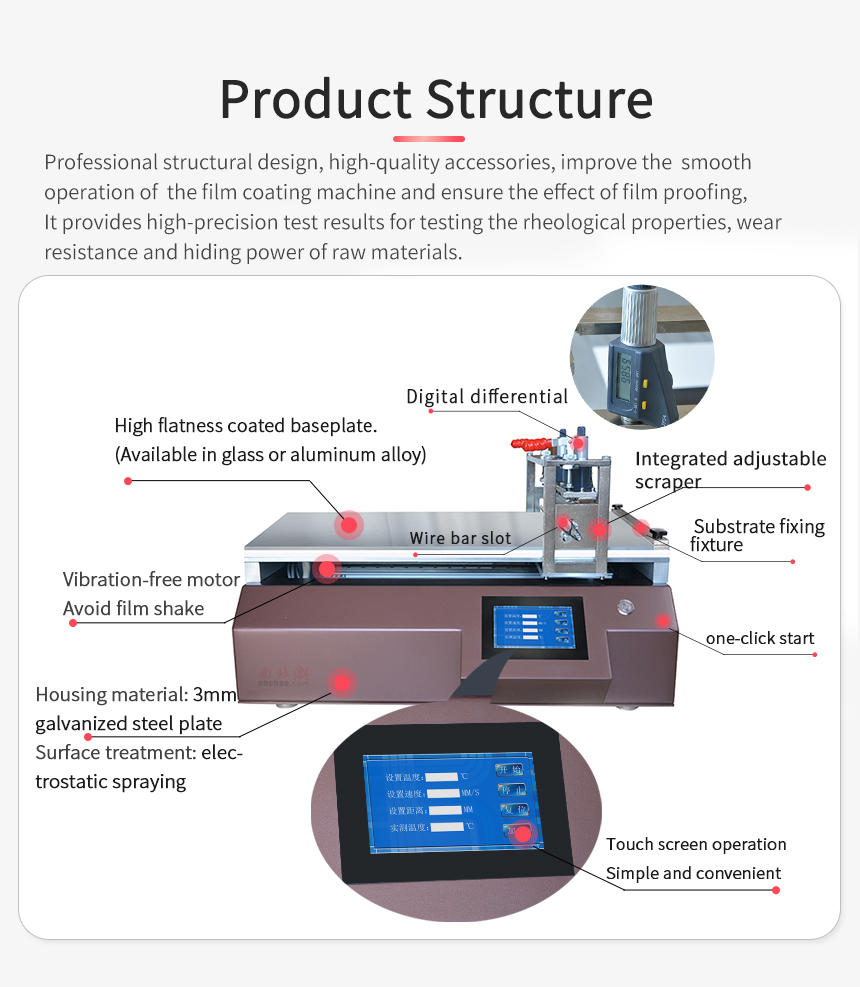

- Coating table material

- aluminum alloy

- Vacuum Area

- 300 * 400Mm (can be customized)

- vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Bar effective application width

- 300mm

- Mayer Rod Thickness Range

- 0~517.5 μm (Spreader thickness according to bar model)

- Mayer Rod Accuracy

- ±0.001mm

- Drawdown blade type

- Removable drawdown blade, easy to clean and replace

- Drawdown blade Accuracy

- ±0.003mm

- Drawdown blade thickness range

- 0~10Mm drawdown blade can be lifted

- Vacuum pump size

- 380*180*280mm

- UV curing area

- 300*400mm

- UV light main peak wave

- 36nm

- UV Light Power

- 400*2W

- UV light curing wavelength

- 350-450nm

- switch

- Aviation plug/separate switch

- Light source spacing

- 18*18mm

- Light board height from Spreader

- 20Mm (support customized adjustable height)

- Host Power Supply

- 220V 50Hz

- Dimension

- 630*410*520mm

- Optional Accessories

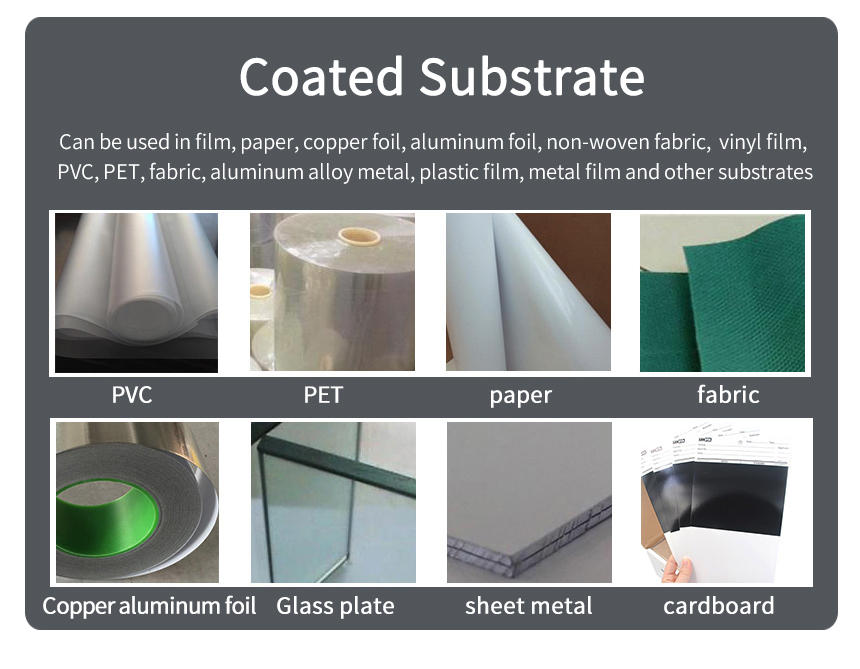

- Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle

- customizable function

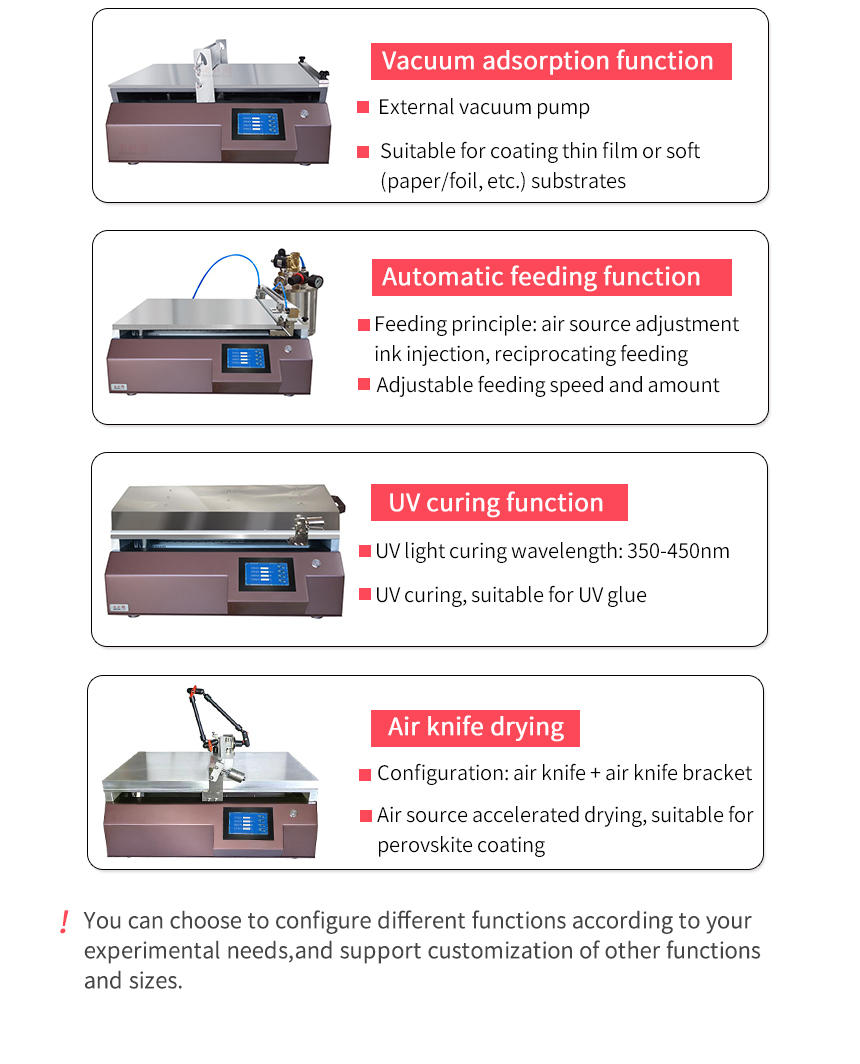

- Jet system device, UV solid inclusion device, automatic inking system

Overview

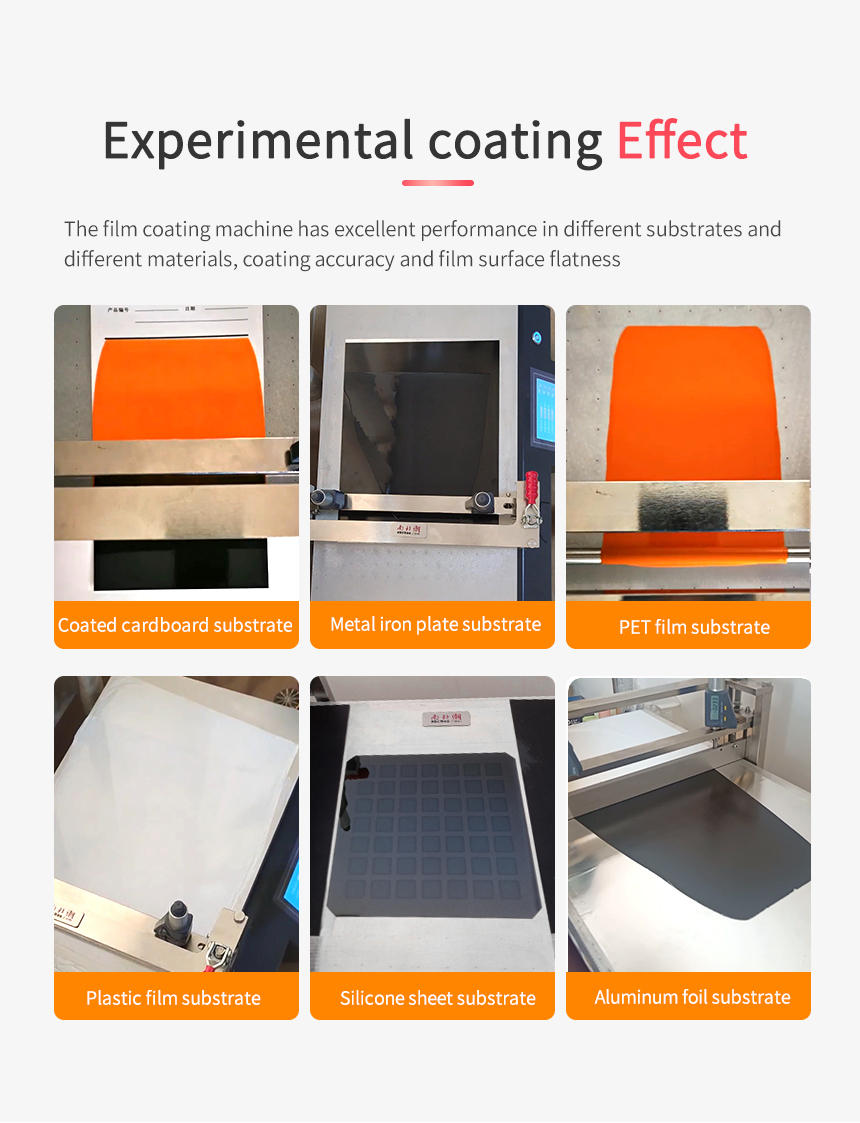

All the coating machines use imported accessories, and the price is cheap, which has been favored by many multinational R & D institutions, many familiar universities and scientific research institutions at home and abroad. By controlling the speed and stable pressure, the coating effect is guaranteed, and the uniformity and smoothness of the coating and gluing are guaranteed.

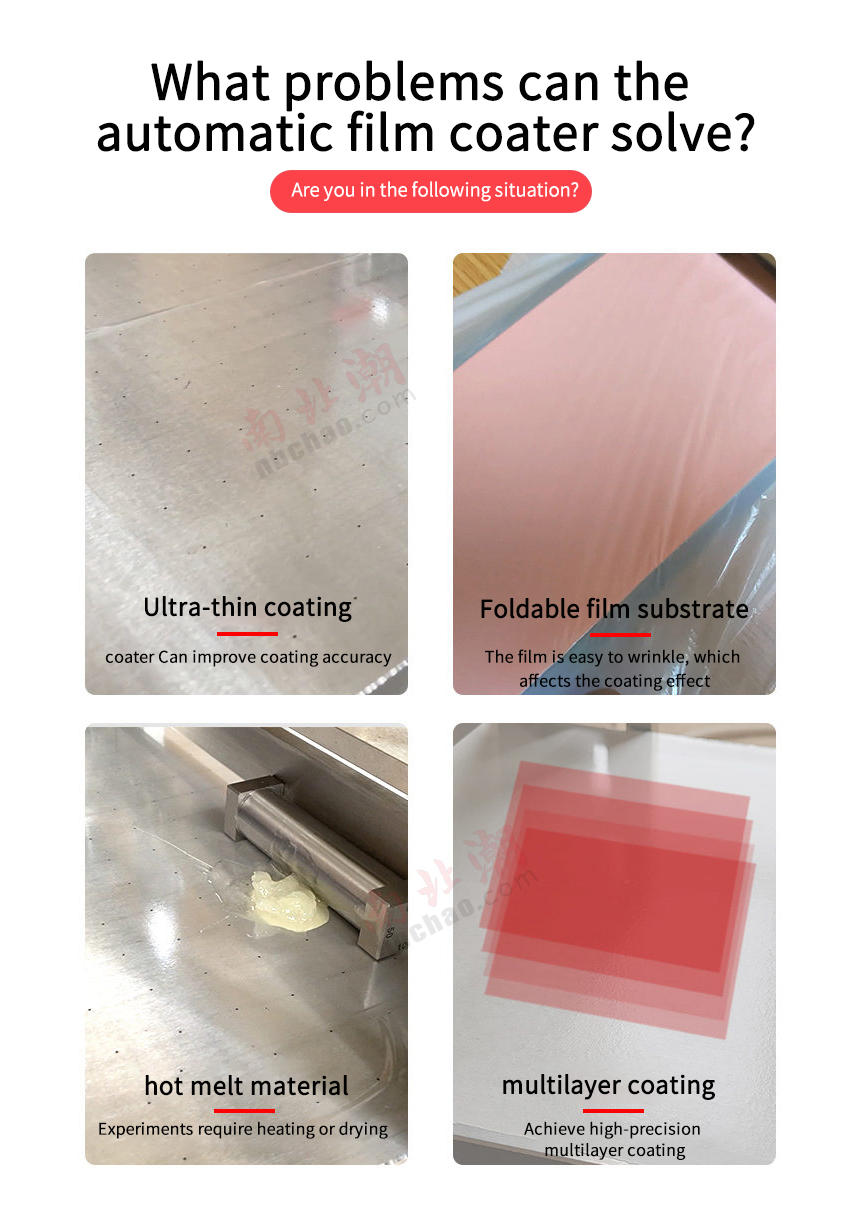

Since the main factors affecting the coating are the coating speed and the pressure applied to the Film Applicator, the coatings painted by hand are often inconsistent, especially the differences between different people are even greater, which makes it difficult to compare the test results between samples. Our company's automatic Film Applicator is carefully designed to enable operators to easily apply accurate wet films on different substrates, greatly improving the reproducibility of the coating film.

TBJ-X2-DJ18 automatic coating machine is a laboratory coating machine with wire rod, removable scraper and vacuum adsorption. It has UV curing function and is equipped with removable scraper. The scraper is easy to disassemble, clean and replace. It is suitable for UV glue, UV ink, etc.

Optional

- 1How to Choose a Film Applicator? Film Applicator Principles, Applications and Selection Steps

Air - 《南北潮商城》

- 2Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 3Experimental Application of Automatic Film Applicator on Glass substrates

- 4Automatic Film Applicator Application of UV Adhesive on Silicon Wafer [Video Demonstration]

- 5Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

- 6Application of Automatic Film Applicator in Phosphor Coating

- 7Application of Automatic Film Applicator in preparing fluorescent diaphragm

- 8Application of Automatic Film Applicator on BOPP Thin

- 9Pressure sensitive adhesive on PET film by Automatic Film Applicator

- 10Application Case of Automatic Film Applicator Coating Metal Powder Solution on Titanium Fiber Felt [With Video]

TBJ-X2-DJ18

TBJ-X2-DJ18