RDS 10 #1/4 "wire-wound Applicator rod film thickness 22.9μm Wire diameter 0.25mm

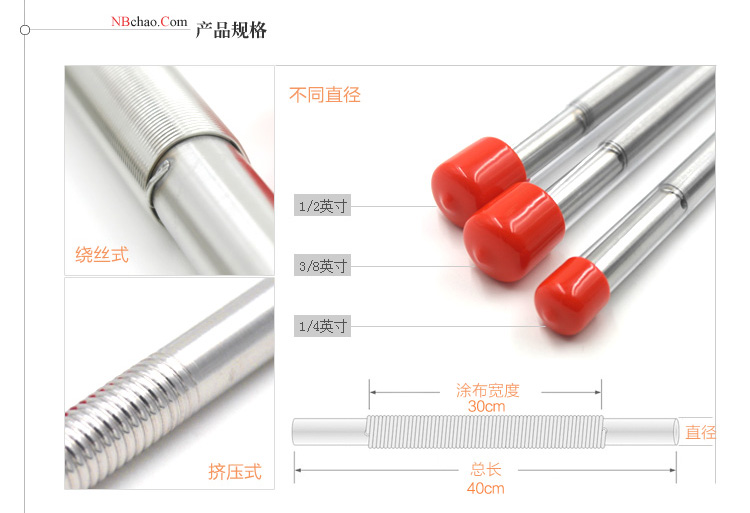

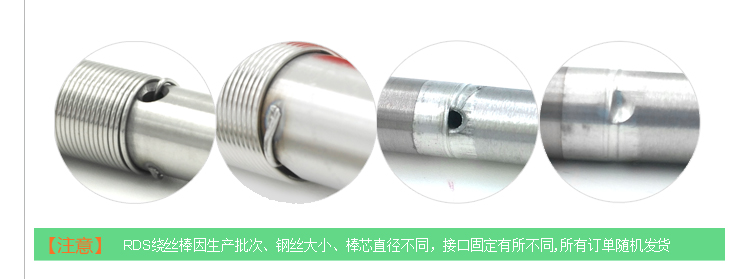

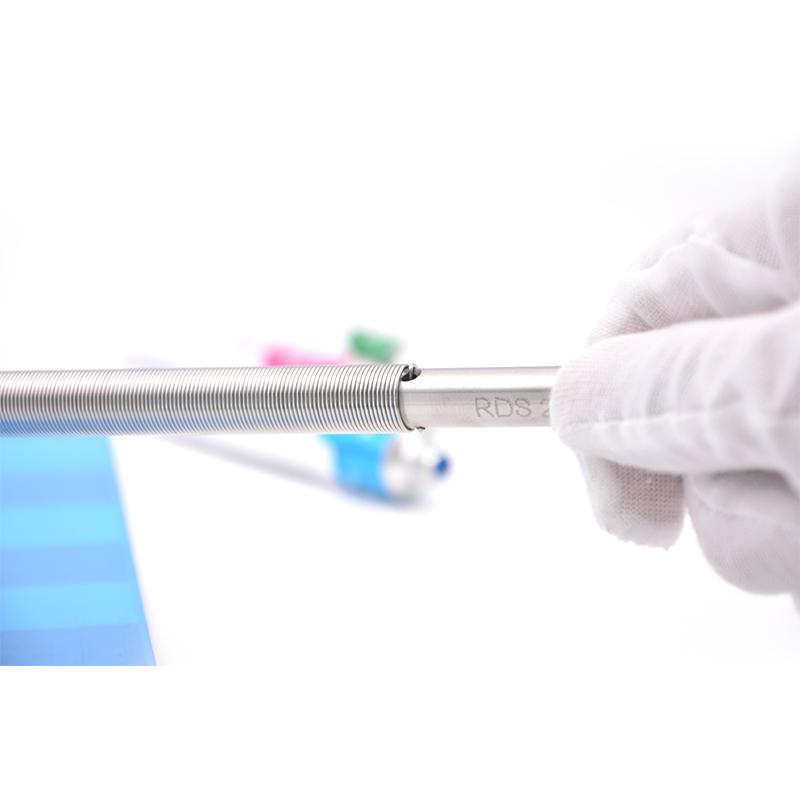

SEWinding process, Wire diameter 0.25mm, rod diameter 6.35mm, the main rod and steel wire are stainless steel, can film 22.9μm.

$156.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

RDS 10 #3/8 "Applicator rod WFT 22.9μm Length 400mm$ 162.00SE

RDS 10 #3/8 "Applicator rod WFT 22.9μm Length 400mm$ 162.00SE -

RDS 10 #1/4 "paint rod Applicator film thickness 22.9μm rod diameter 6.35mm$ 156.00SE

RDS 10 #1/4 "paint rod Applicator film thickness 22.9μm rod diameter 6.35mm$ 156.00SE -

RDS 10 #1/2 "Steel Wire Drawdown Rod film thickness 22.9μm Wire diameter 0.25mm$ 181.00SE

RDS 10 #1/2 "Steel Wire Drawdown Rod film thickness 22.9μm Wire diameter 0.25mm$ 181.00SE -

RDS 10 #1/2 "Spreader 22.9μm Applicator rod$ 181.00SE

RDS 10 #1/2 "Spreader 22.9μm Applicator rod$ 181.00SE -

RDS 10 #3/8 "Molded Wet Rubber Scraper 22.9μm Glue Stick$ 162.00SE

RDS 10 #3/8 "Molded Wet Rubber Scraper 22.9μm Glue Stick$ 162.00SE

RDS 10# 1/4 Applicator rod 1/4SPEC

RDS 10# 1/4 Applicator rod 1/4Details

RDS 10# 1/4 Applicator rod 1/4Packing list

- SKU

- NB004881

- Production process

- wire-wound

- WFT

- 22.9μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.25mm

- principle

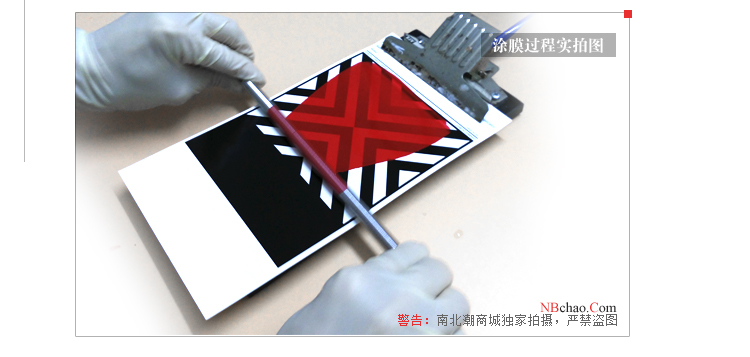

- Through different grooves, ink control is applied to film, paper and other substrates by roller painting and scratch coating. Universal for high-precision wire-rod film applicators.

- function

- Coating is used to uniformly coat the surface of the substrate to form a flat, uniform thickness coating.

10# 1/4

Applicator rod 1/4

Winding process, Wire diameter 0.25mm, rod diameter 6.35mm, the main rod and steel wire are stainless steel, can film 22.9μm.

|  |  |

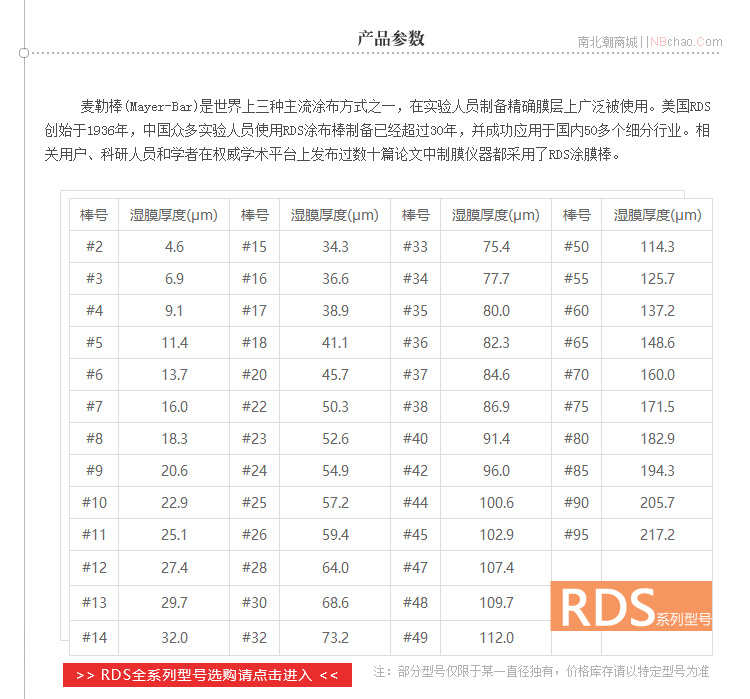

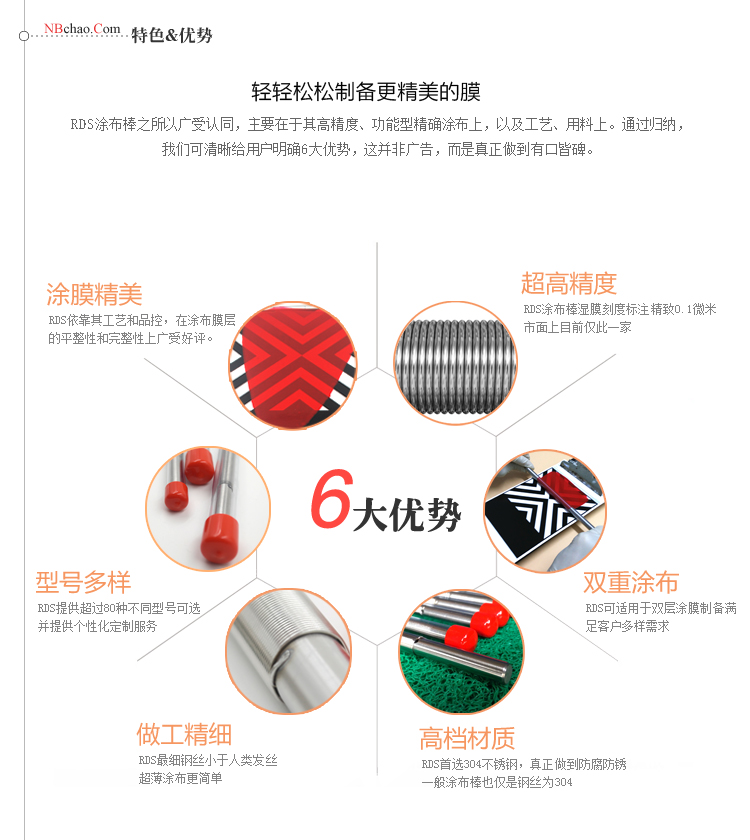

The wet film thickness of the U.S. RDS#10 squeegee rod coating is 22.9 microns, which is divided into two types: wire-wound rods and forming rods. The forming rods are processed on a steel rod through a special extrusion process to have continuous grooves. The advanced coating rod has the advantages of continuous silk and easy cleaning, and is deeply loved by some users in the industry. In addition, the wire winding rod is developed according to the traditional Meyer rod testing principle, and it will be more widely used in the industry. RDS forming rods and wire winding rods of the same type have the same thickness and precision of the coating film, and the difference lies in the coating amount.

Optional

FAQ

QWhat does it mean to buy a 10 #rds rod, quarter, three-eighths, and one-half?

A

Hello, this is the diameter of the rod in inches, 1/4 is 6.35mm, 3/8 is 9.5mm, and 1/2 is 12.7mm.

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

QCan this RDS film scraper correspond to GB/T13217.1?

A

Yes, please refer to the NBchao standards page for specific standards.

QWater-based polyurethane wood coatings prepare film layers, can I choose this model Mayer-Rod?

A

Water-based polyurethane wood lacquers can choose Mayer-Rod as the film equipment, and the specific model selection should be evaluated according to the wet film you want to prepare.

QCan this rod be coated with PEDOT emulsion on PET film?

A

OK

Knowledge

- 1Advantages and disadvantages of Mayer-Rod

- 2Application of Mayer Rods in composite coating prepative

Standard

- 1GB/T 22374-2018《Floor coating》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3GB/T 7044-2022《Colour carbon black》

- 4GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 5HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 6HG/T 5370-2018《Waterborne coatings for bicycles》

- 7HG/T 3951-2007《Water based colorants for architectural coatings》

- 8HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 9ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 10GB/T 13217.1-2009《Test method for colour of liquid ink》

10# 1/4

10# 1/4