CHINA Small hot-melt adhesive Continuous Film Applicator NBC-6025H Continuous Coater, baseplate heating + drawdown blade heating

SE

Factory NBC-6025H Small hot-melt adhesive Film ApplicatorSPEC

Factory NBC-6025H Small hot-melt adhesive Film ApplicatorDetails

Factory NBC-6025H Small hot-melt adhesive Film ApplicatorPacking list

- SKU

- NB048894

- Coating Method

- continuous scratch coating

- Effective application width

- ≤ 300mm, adjustable through baffle

- Drawdown blade adjustment

- manual adjustment

- Drawdown blade diameter

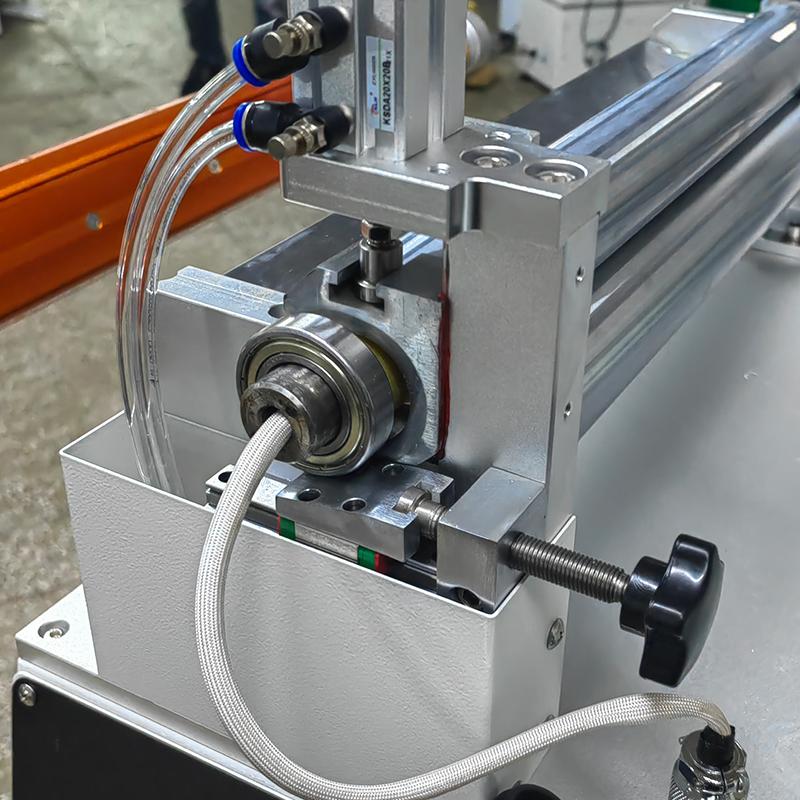

- Ф80mm

- Drawdown blade heating temperature

- RT+~150°C

- Spreader thickness range

- 0.01mm~2mm

- Minimum gluing thickness

- 0.01Mm (depending on the slurry, refer to the material requirements)

- Coating surface density

- ≤ +/- 1.5% (including substrate, excluding edge abnormal areas, see product evaluation for sampling measurement standards)

- Coating Speed

- 2~ 4.5M/min forward and reverse stepless speed change, recommended Spreader speed: 4.5m/min

- Film Accuracy

- +/- 0.003mm (depending on slurry, reference material requirements)

- Regulator Graduation

- 0.001mm

- Indication Display mode

- digital display

- Heating device

- Chute heating

- Heating mode

- Heating rod

- Temperature range

- RT+~200℃

- box Volume

- About 0.5L

- Width of guide roller

- 350mm

- substrate width

- Max.300mm

- Back roller diameter

- Ф150mm

- Reel diameter

- 3 inches.

- winding diameter

- Max.Ф200mm

- Applicable materials

- hot-melt adhesive

- Machine Power

- 1050W

- Host Power Supply

- AC220V (single phase) 50Hz

- Machine size

- 1280*600*660mm

- Machine Weight

- About 120kg

- gas source

- 0.5-0 MPa compressed air

- unwinding diameter

- Max.Ф200mm

Introduction

The continuous hot melt adhesive coating and lamination testing machine is a high-precision modular coating station mechanism combination assembly, which can be used for continuous coating proofing or small batch production in the laboratory. It can apply hot melt pressure sensitive adhesive directly to a heat-resistant substrate, or it can apply the adhesive on the release liner first, and then transfer the adhesive film to different material surfaces, such as paper, plastic, model metal film, etc.

Performance characteristics:

The whole machine is a high-precision modular coating station structure combined assembly.

The dial gauge is used as the indexing head to accurately fine-tune the coating gap between the upper and lower rubber wheels to control the coating thicknessDegree. The minimum gluing thickness is:0.01mm。 When the thickness is set, the rubber wheel can be locked indirectly to prevent the gap from changing.

The maximum coating width is 300 mm (effective coating width 280 mm). Coated in a wide formatTwo Teflon baffles in the glue tank to adjust. It can be applied and glued in any length, automaticallyRewinding.

Forward and reverse continuously variable speed, recommended coating speed: 4.5m/min (speed 2-4.5m/min adjustable) unwinding reel adjustable knob to change tension unwinding. Receiving rollsThe shaft can be adjusted mechanically for tension control.

The warming rod, glue wheel and glue tank can be quickly disassembled and separated from the machine body to remove the residual glue.

NBC-6025H

NBC-6025H