Factory Direct HYQ-Z-103 automatic Contact Angle Analyzer, contact angle Tester

SE

Factory HYQ-Z-103 Automatic Contact Angle AnalyzerSPEC

Factory HYQ-Z-103 Automatic Contact Angle AnalyzerDetails

Factory HYQ-Z-103 Automatic Contact Angle AnalyzerPacking list

- SKU

- NB049338

- Measurement Accuracy of contact angle

- ±0.1°

- Contact angle test method

- Automatic fitting measurement, baseline fitting measurement, manual three-point measurement, area measurement method.

- Contact angle analysis method

- Automatic analysis of contact angle and manual point measurement.

- Injection system movement

- 35mm up and down, 35mm left and right

- Sample stage movement

- Left and right 100mm front and rear 40mm

- Microscope movement

- Up and down 80mm (fine-tuning 3mm)

- Sampling system

- Software automatic precision sampling system, injection Accuracy of 0.1 μl, direct injection of liquid, no need to go through the pipeline, to avoid bubbles, cleaning and other problems

- data preservation

- Automatically save measurement data and pictures, view and delete historical test data. Instant screenshots; export any picture sheet

- Microscope

- 0.7-4 High Definition Microscope

- scope

- Directly convert the measured contact angle to calculate the surface tension or surface energy (range: 0~60mN/m)

- Test sample Countertop size approx

- 200mm×125mm

- Maximum sample size

- 300Mm (length) × 150mm (width) × 10mm (thickness)

- Product size approx

- 500Mm (length) × 200mm (width) × 550mm (height)

- Power Supply

- 220V

Introduction

HYQ-Z-103 Contact Angle Tester for Measuring Solids. The contact angle between the three phases of a liquid and a gas. By measuring the contact angle, the adhesion of the liquid to the solid, the surface tension of the solid and the surface energy of the solid are calculated and measured. The instrument is widely used in petroleum, chemical, pharmaceutical, papermaking, dyes and various new materials research and manufacturing fields. Microcontrol technology is used to transfer the ingested images into a computer for saving, analysis, and printing. The speed is fast, the data is accurate, and the operation is convenient.

Product principle

The contact angle is defined as the angle between the gas-liquid interface and the solid-liquid interface at the interface of solid, liquid and gas, and the contact angle is the scale that shows the humidity of the solid surface, which is determined by using most of the solid droplets, and the low contact angle indicates that the humidity is high (hydrophilic) and the surface is easy to paste. The contact angle of the liquid in contact with a flat solid surface is determined by the end point of the water droplet curve in the liquid-solid-gas junction and the contact point of the solid surface.

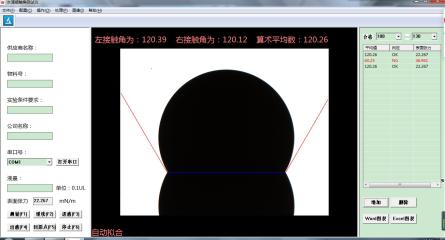

Software Introduction

Software function introduction and test method: The Contact Angle Analyzer software is designed with Windows operation interface structure. Beautiful and novel, simple and generous operation. It is clear to the user at a glance, and the main function keys are all placed in the toolbar at the top of the interface. It is very easy to select the operator. Functions that are not commonly used are placed in the submenu of the processing bar in the toolbar, and the operator can extract and use them according to the experimental requirements.

Before starting the test, connect the power supply of the computer and monitor. Plug in the power supply behind the light source box of the instrument host. Turn on the computer, double-click the contact angle software icon on the computer screen, the contact angle software will open, and the following interface will appear.

HYQ-Z-103

HYQ-Z-103