Factory Direct Rgd - 0.5/300 Y Desktop Unwinding Traction Film Applicator Copper Foil Aluminum Foil Coater

SE

Factory Rgd-0.5/300Y Desktop Unwinding Traction Film ApplicatorSPEC

Factory Rgd-0.5/300Y Desktop Unwinding Traction Film ApplicatorDetails

Factory Rgd-0.5/300Y Desktop Unwinding Traction Film ApplicatorPacking list

- SKU

- NB049357

- process

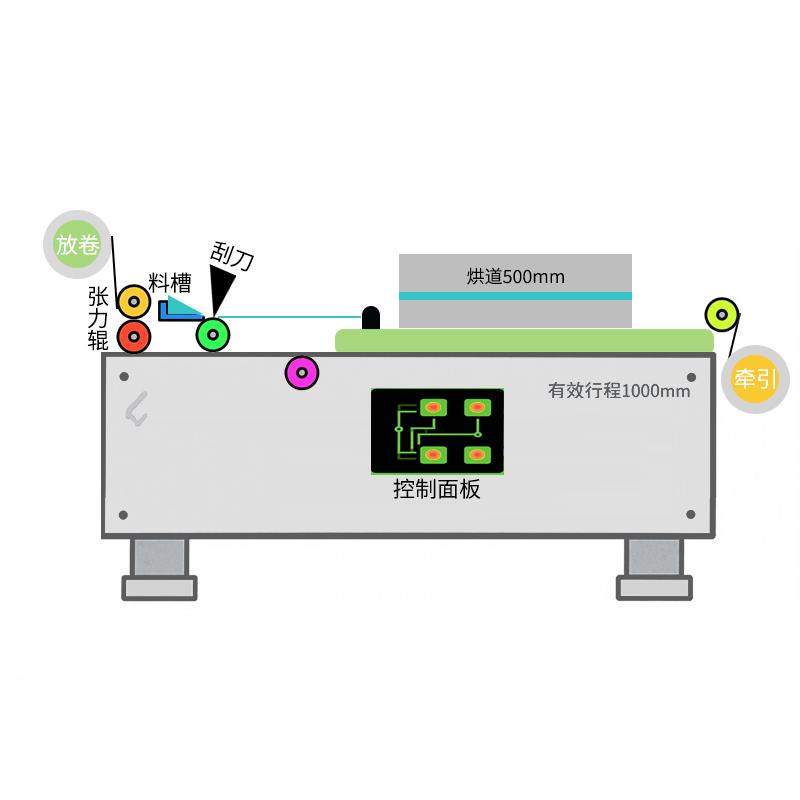

- Roll → Scratch → Drying → Traction

- Coating method

- scraping

- Effective application width

- 100~300Mm (width adjustable)

- Coating thickness

- 0-5000A (thickness adjustable)

- Spreader area

- Width 300 * Length 1000mm

- wide range of materials

- 100-300mm

- Drawdown blade Accuracy

- ±0.003mm

- Thousand head resolution

- 0.001mm

- Tension control range

- 1-50N

- Motor type

- Servo motor

- unwinding method

- Roll up or down, maximum roll diameter 200mm

- tension control

- Tension can be set, PLC program control, forming a closed-loop tension control

- unwind drive

- Magnetic particle control

- guide roller

- Hard anodic oxidation treatment on roller surface

- roll over

- φ 40mm × 300mm, aluminum roller surface anode treatment, mirror polishing treatment

- Mechanical speed

- Max.5m/min; production speed depends on actual Spreader process, material and degree of drying

- Oven structure style

- Electric heating tube

- Oven length

- A total of 1 oven; oven length 500mm/section, a total of 500mm

- Oven temperature

- Temperature range: 40 ℃~ 150 ℃ inside the box (Environmental temperature 20 ℃), temperature Accuracy: Temperature control Accuracy +/- 2 ℃

- Box material

- The insulation layer is rock wool board/silicic acid board

- Electric heating part

- Electric heating, 5kw/section, total 5kw, infrared heating

- temperature control

- Independent PID control, set on the operation screen.

- Hot air circulation system

- Single layer of circulating air duct, frequency conversion control, air Volume adjustment, frequency conversion control and pipeline air valve adjustment air Volume equilibrating

- Control mode

- Equipment reference speed

- operation button

- Touch screen button switch control and emergency stop, start, stop, deviation correction manual/automatic press

- operation

- Oven clamshell type, by opening the oven door, manually piercing the foil.

- foil

- Copper foil, aluminum foil and PET film (material thickness 6-30um)

- slurry

- Battery slurry, electrolysis fluid (viscosity range < 80000cps)

- Substrate Weight

- Max.300Kg

- Device size

- About 2000mm × width 600mm × height 800mm (subject to actual customization)

Introduction

Rgd-0.5/300Y desktop unwinding traction film coating machine, sold directly by the factory, suitable for coating operations of a variety of materials. It covers unwinding, scraping, drying, traction and other processes, and can process foils such as copper foil, aluminum foil and PET film, with battery slurry, electrolyte and other slurries. The equipment can coat on an area of 300 mm wide * 1000mm long, and the applicable width of the material is 100 - 300mm, which can provide users with efficient and accurate coating solutions in actual production.

Features

Flexible and adjustable coating parameters - the effective coating width can be flexibly adjusted in the range of 100-300mm, and the coating thickness can be adjusted from 0 - 5000um.

High-precision coating - the scraper accuracy is up to ±0.003mm, and the resolution of the microbilehead is up to 0.001mm, which ensures the high precision of the coating process and makes the coating more uniform.

Stable tension control - the tension control range is 1-50N, which is controlled by PLC program to form a closed-loop tension control, and the unwinding drive is controlled by magnetic powder to ensure the stability of the material tension during the unwinding process and avoid material deformation or wrinkles. The unwinding method can be selected up or down, and the maximum roll diameter is 200mm.

High-quality guide roller and roller - the surface of the guide roller is hard anodized, the specification of the roller is Φ40mm×300mm, aluminum roller is used, the surface anodic treatment and mirror polishing treatment are carried out to ensure the stability of the material in the transmission process.

Efficient heating and temperature control – the oven uses electric heating tubes, a total of 1 section, and a length of 500mm. The temperature range is 40°C - 150°C (at ambient temperature 20°C), and the temperature control accuracy can reach ±2°C. The electric heating power is 5kw/section, a total of 5kw, and is equipped with infrared heating. Independent PID control, the temperature can be easily set on the operation screen. The hot air circulation system adopts a single-layer design of circulating air duct, and adjusts the balance of air volume through frequency conversion control and pipeline damper to ensure uniform temperature in the oven and improve drying efficiency.

Advanced drive and speed control – the motor type is servo motor, and the mechanical speed is Max. 5m/min, the production speed is determined according to the actual coating process, material and drying degree, the operation is stable and can be flexibly adjusted according to the actual situation.

Convenient operation mode - touch screen button switch control, with emergency stop, start, stop, deviation correction manual/automatic buttons, easy to operate. The oven is clamshell type, and the foil can be threaded manually by opening the oven door, which is convenient and fast.

Wide range of application - suitable for copper foil, aluminum foil and PET film and other foils (material thickness 6 - 30um), as well as battery paste, electrolyte (viscosity range< 80000cps) and other slurries, the maximum weight of the substrate can reach 300Kg.

Customized design - the size of the equipment is about 2000mm× width is 600mm× height is 800mm (subject to actual customization), which can be customized according to the actual site and production needs of users.

Rgd-0.5/300Y

Rgd-0.5/300Y