Tensile Tester NBC-50kN Microcomputer controlled electronic universal testing machine, maximum test force 50kN

zy NBC-50kN Microcomputer-controlled electronic universal testing machineSPEC

zy NBC-50kN Microcomputer-controlled electronic universal testing machineDetails

zy NBC-50kN Microcomputer-controlled electronic universal testing machinePacking list

- SKU

- NB049423

- maximum test force

- 50kN

- Measurement range

- 0.4%--100%

- Test force indication Accuracy

- Better than indication +/- 0.5%

- Test force resolution

- 1/300000 (full undivided or equivalent to 6 gears)

- Measurement Accuracy of beam displacement

- Resolution higher than 0.0025mm

- Measurement Accuracy

- +/- 0.5% (in the range of 0.2-10mm)

- Test speed range

- 0.01 - 500mm/min, stepless speed regulation

- Speed control Accuracy

- ±1%(0.01~10mm/min); ±0.5%(10~500mm/min)

- Constant force, constant deformation, constant displacement control range

- 0.2%-100%FS

- Constant force, constant deformation, constant displacement control Accuracy

- When the set value is < 10% FS, within +/- 1.0% of the set value, and when the set value is ≥ 10% FS, within +/- 0.1% of the set value

- Deformation rate control Accuracy

- Within the +/- 2.0% setting value when the rate is < 0.05% FS, within the +/- 0.5% setting value when the rate is ≥ 0.05% FS

- Test space

- A. Stretching space: 600mm B. Compression space: 700mm

- Fixture form

- Wedge clamp body, flat jaw 0-7mm, round jaw Ø 4-Ø 9mm

- Pressure plate size

- φ100mm

- Power supply for the whole machine

- Single Phase, 220V +/- 10%, 50Hz, Power 1.5 kW

- Operating Environment

- Room temperature - 35 ℃, Relative Humidity does not exceed 80%

- Host size

- 760×500×1750mm

- Weight

- 500kg

Introduction

The microcomputer control electronic universal testing machine is a new generation of microcomputer controlled electronic universal testing machine specially designed for colleges and universities and scientific research institutes. The computer system through the full digital controller, through the speed control system to control the servo motor rotation, through the deceleration system deceleration through the precision ball screw pair to drive the moving beam up and down, to complete the sample tensile, creep, hardness, compression, bending, shear and other mechanical properties of the test, in addition to a wide variety of test attachments, in the metal, non-metal, composite materials and products of mechanical properties test, has a very broad application prospects. The machine is widely used in building materials, aerospace, machinery manufacturing, wire and cable, rubber and plastics, textiles, home appliances and other industries of material inspection and analysis, is a scientific research institutions, colleges and universities, industrial and mining enterprises, technical supervision, commodity inspection and arbitration and other departments of reliable testing equipment.

Scenario description

host

The main machine adopts a high-rigidity portal frame structure, with high strength and small deformation

Imported high-precision ball screws are used to drive efficiently and smoothly

The transmission part is driven by arc tooth synchronous belt, and there is no gap in both directions during the transmission process

AC servo motor and drive system are used to ensure stable transmission and stable torque, with overcurrent, overVoltage, overload and other protection devices, and the speed regulation ratio can be larger than 1:100000

The clamp is specially designed, the clamping is firm, the operation is convenient, and there is no jaw slippage

The special process ensures the coaxiality of the testing machine, and eliminates the influence of irregular specimens on the sensor

Control system

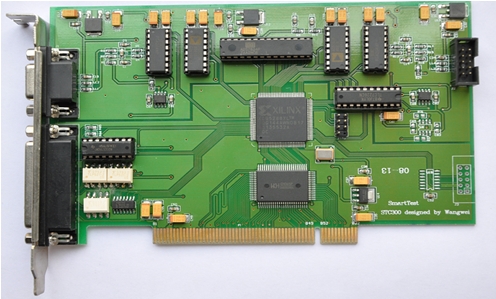

The STC300 all-digital closed-loop measurement and control system has many advanced features and technological innovations, which are mainly reflected in:

1. Four closed-loop controls of test force, sample deformation, beam displacement and test process are realized

2. The data acquisition system consists of 4 high-precision 24-bit A/D conversion channels. The highest resolution is 1/300000, and the whole process is not divided

3. Select BB, AD, Xilinx and other original integrated devices, fully digital design

4. In line with PCI bus standards, microcomputer automatic identification and installation, so as to achieve "plug and test"

5. The electronic measurement system does not have analog components such as potentiometers, which ensures interchangeability and is convenient for maintenance and replacement

NBC-50kN

NBC-50kN