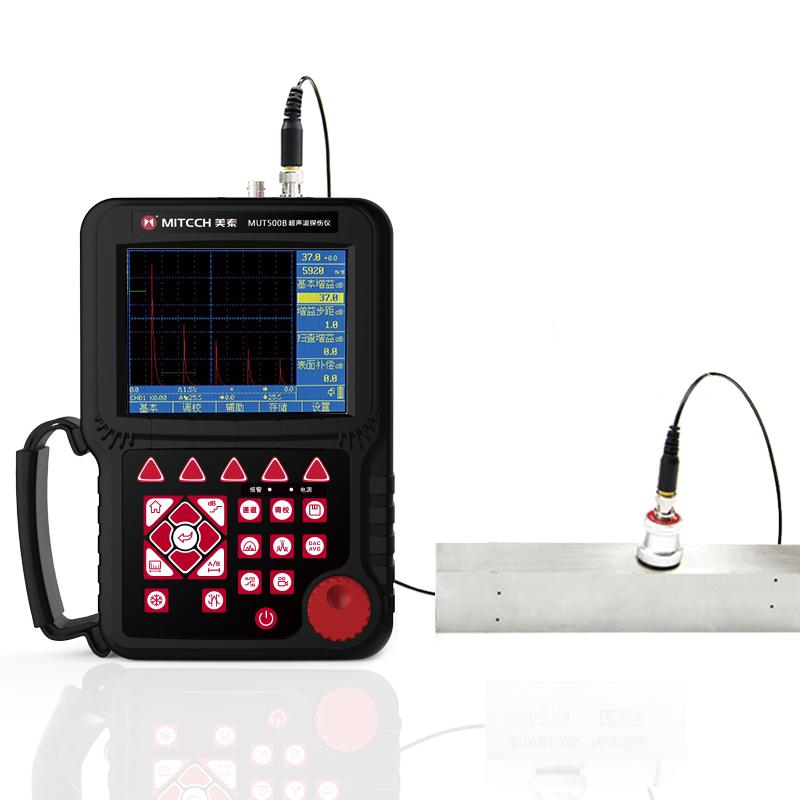

MITECH MUT500B Portable digital Ultrasonic Flaw Detector

mitech MUT500B Ultrasonic Flaw DetectorSPEC

mitech MUT500B Ultrasonic Flaw DetectorDetails

mitech MUT500B Ultrasonic Flaw DetectorPacking list

- SKU

- NB049540

- detection range

- (0~6000)mm

- Frequency

- (0.5~10)MHz

- Speed of sound

- (1000~15000)m/s

- Dynamic range

- ≥36dB

- Vertical Linearity

- ≤3.0%

- Horizontal Linearity

- ≤0.2%

- Display resolution

- 320*240

- resolution

- >40dB(5P14)

- Blind spot

- 5MM

- Sensitivity margin

- > 60dB (200mm depth with 2 flat bottom holes)

- digital suppression

- (0~80) %, does not affect linearity and gain

- video duration

- without

- electrical noise level

- ≤10%

- Probe type

- Straight probe, oblique probe, dual crystal probe, penetration probe

- gate

- Inlet gate, loss gate; single gate reading, double gate reading

- alarm

- Beep alarm, LED light alarm

- Flaw detection standard

- Built-in common flaw detection standards in various industries, direct call, convenient and fast

- Weld diagram

- The weld shape parameters can be set, and the weld pattern and the position of the defect in the weld can be visually displayed during the flaw detection

- Automatic calibration

- Probe zero and probe angle (K value) Automatic calibration function; Speed of sound automatic measurement function

- Memory

- Real-time retrieval of the highest defect wave and recording of the peak defect echo

- positioning

- Real-time display of defect level, depth (vertical), sound path position

- defect quantification

- Real-time display of defect equivalent dB values

- defect characterization

- Through the echo envelope waveform, it is convenient for manual experience to judge

- surface correction

- For flaw detection of curved workpieces, the circumferential position of defects can be displayed in real time

- DAC/AVG

- Linear dispersion is automatically generated with unlimited sampling points, and can be compensated and corrected. Linear dispersion automatically floats with gain, automatically expands with sound path, and automatically moves with delay. AVG Linear dispersion can display any aperture

- AWSD1.1

- American Welding Society standard provides a dynamic reflection "defect rating" for various AWS weld inspection applications. Avoids manual calculations and improves inspection efficiency (optional)

- Crazing bathymetry

- Automatic measurement and calculation of crazing depth using diffraction waves

- Door widening

- Amplify echo details for easy echo analysis

- continuous recording

- Record waveforms in real time, store and playback waveforms

- waveform freezing

- Freeze the waveform displayed on the screen for easy defect analysis

- echo coding

- Display 1 to 6 echo display areas in different Colors, better distinguish between primary and secondary waves, easy to determine the location of defects

- B-scan

- (Ordinary B-scan) Real-time scanning and cross-sectional display make detection results more intuitive

- Environmental temperature

- (-10~50)℃

- Relative Humidity

- (20~95)%RH

- Power Supply

- Direct current (DC) 9V; lithium battery works continuously for more than 10 hours

- Power saving method

- Low power design

- Working time

- More than 10 hours

- Protection level

- IP64

- Communication interface

- USB2.0 high-speed communication transmission interface

- PC software

- Yes.

- working language

- Chinese

- exterior size

- 263×170×61(mm)

- Machine Weight

- 5.2KG

Overview

MUT500B is a high-performance, portable, all-digital ultrasonic flaw Detector designed for industrial non-destructive testing. It uses advanced ultrasonic technology to quickly and accurately detect internal defects (e.g. cracks, inclusions, porosity, etc.) in the workpiece, and supports defect location, evaluation and diagnosis. It is suitable for laboratory research, engineering on-site testing and other scenarios, and meets the strict needs of manufacturing, iron and steel metallurgy, metal processing, chemical and other industries. The ultra-large range of 0-6000mm covers a wide range of testing needs, with high-efficiency and low-power design and large-capacity lithium-ion battery, the battery life is more than 8 hours, and the standby time can be up to several months.

Application

Industrial Manufacturing:Quality control of iron and steel metallurgy, metal processing, chemical equipment

Special Equipment:Safety inspection and life assessment of boilers and pressure vessels

Transportation:In-service safety inspection of aerospace and railway tracks

Energy & Power:Defect diagnosis of pipelines and welded structures

Technical principle

Based on the propagation characteristics of ultrasonic waves in materials, non-destructively detect internal and surface defects (such as cracks, porosity, slag inclusions, etc.) of materials by analyzing signal changes such as acoustic wave reflection and attenuation. This technology offers the following advantages:

High sensitivity – detects even the smallest defects

High penetration – suitable for a wide range of material thicknesses

Efficient and portable – fast detection and lightweight equipment

Safe and environmentally friendly - no radiation, harmless to the human body

Core features:

✔ Intelligent operation: full Chinese interactive interface, shortcut button + digital shuttle wheel design, smooth and efficient operation

✔ Ultra-long battery life: The modular high-capacity lithium battery supports 8 hours of continuous work, can be charged offline, and standby for months when idle

✔ Rugged and portable: Ergonomic design, one-handed hold, suitable for high-intensity field operations

✔ Adaptation to all environments: working temperature -10°C~50°C, humidity 20%~95%RH, to cope with complex Operating Conditions

MUT500B

MUT500B