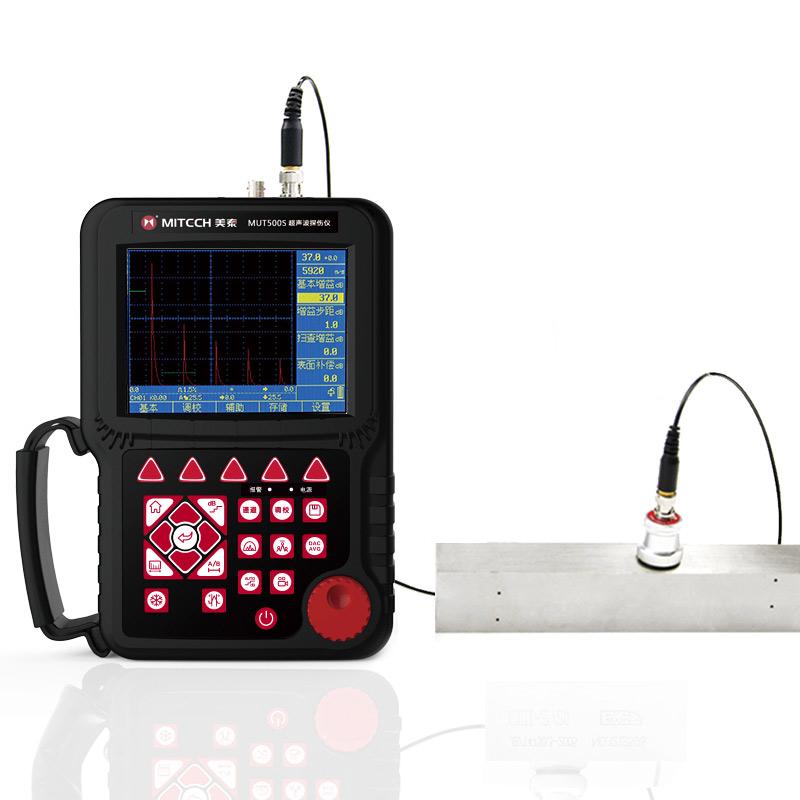

MITECH MUT500S vehicle inspection special Ultrasonic Flaw Detector

mitech MUT500S Vehicle inspection special Ultrasonic Flaw DetectorSPEC

mitech MUT500S Vehicle inspection special Ultrasonic Flaw DetectorDetails

mitech MUT500S Vehicle inspection special Ultrasonic Flaw DetectorPacking list

- SKU

- NB049541

- Plug socket

- BNC/LEMO optional

- Total gain

- 110 dB (with 0.1dB, 1dB, 2dB, 6dB step values)

- Gate reading

- Single and double gate readings are optional; peak readings in the gate

- Filter band

- (0.5~ 10) MHz can be automatically matched according to the probe Frequency, no need to manually set

- Detection method

- Positive half-wave, negative half-wave, full-wave, RF detection

- Hardware real-time sampling

- High resolution 10-bit AD converter, sampling speed 160MHz, high waveform fidelity

- probe damping

- 100Ω, 200Ω, 400Ω optional, to meet the different working requirements of Sensitivity and resolution

- pulse width

- Continuous adjustment in the range of (0.1 to 0.512) µs to match probes of different Frequencies

- pulse amplitude

- 300V, 500V, 700V grading selection, suitable for a wide range of probes

- Relative Humidity

- (20~95)%RH

- Environmental temperature

- (-10~50)℃

- exterior size

- 263×170×61(mm)

- standby time

- > 6 hours

- Power Supply

- Direct Current (DC) 9V

- alarm

- Beep alarm, LED light alarm

- gate

- Inlet gate, loss gate; single gate reading, double gate reading

- Probe type

- Straight probe, oblique probe, dual crystal probe, penetration probe

- electrical noise level

- ≤10%

- digital suppression

- (0~80) %, does not affect linearity and gain

- Sensitivity margin

- > 55dB (200mm deep with 2 flat bottom holes)

- resolution

- >40dB(5P14)

- Horizontal Linearity

- ≤0.4%

- Vertical Linearity

- ≤3.0%

- Dynamic range

- ≥36dB

- Speed of sound

- (1000~15000)m/s

- detection range

- (0~9999) mm (steel medium and longitudinal waves)

Overview

MUT500S special metal flaw Detector for vehicle inspection, using integrated circuit technology and display screen. Based on the principle of ultrasonic propagation, this instrument can accurately and sensitively detect, locate, evaluate and diagnose a variety of defects inside the workpiece. It can effectively detect flaws for the specific application of the vehicle inspection industry, and detect the illegal chiseling, repairing, grinding, gasketing, repainting, unauthorized re-engraving and other phenomena of the vehicle identification code conveniently and efficiently, and is widely used in the fields of motor vehicle safety technical inspection, manufacturing, chemical industry, etc., with high quality and low price, and is the choice of practical and economical ultrasonic testing instruments.

Features

Gate alarm

Door position, door width and door height can be adjusted arbitrarily; B gate can be set up wave alarm or wave loss alarm; Alarm and shutdown of beeps and LED lights (LED lights are very effective in noisy environments) in the gate.

Data storage

The instrument has a built-in mass memory, and the data and files will not be lost due to the power failure of the instrument, including channel parameters, waveform pictures and video files. It supports 50 sets of flaw detection parameter channels, can pre-adjust the combined parameters of various probes and instruments, and freely set the flaw detection standards of various industries; It can store 1000 flaw detection echo signals and parameters, which can be stored, read out and transmitted through USB interface.

Real-time clock

Real-time flaw detection date and time tracking record, and record storage

Communication interface

USB2.0 high-speed communication transmission interface, you can also use special software to upload and download data through USB.

Battery module

The high-capacity lithium battery module is easy to disassemble and assemble, can be charged independently or online, and has a continuous working time of more than 10 hours

Flaw detection function

Flaw detection standards: Built-in commonly used flaw detection standards in various industries, which can be called directly, which is convenient and fast

Operating system: with Chinese "next" prompt function, "fool-style" software system, simple operation

Weld diagram: the weld morphology parameters can be set, and the weld diagram and the position of the defect in the seam can be visually displayed in the flaw detection. Automatic sound velocity measurement function

Peak memory: real-time retrieval of the highest defect wave, record the maximum defect value

Defect location: Real-time display of defect level, depth (vertical), and sound path position

Defect quantification: The dB value of the defect equivalent is displayed in real time

Defect qualitative: through the echo envelope waveform, it is convenient for manual experience judgment

Surface correction: It is used for surface workpiece flaw detection, and the circumferential position of defects can be displayed in real time

Digital-analog dual-use: AVG curve can be omitted, and the bottom wave gain method is used to measure the dB value, so as to achieve digital-analog dual-use, which is convenient for operation Ф value calculation: when the straight probe forging flaw detects the defect peak echo, it is automatically calculated and displayed, and the defect equivalent size DAC/AVG is displayed: the curve is automatically generated, the sampling point is not limited, and compensation and correction can be carried out. The curve automatically floats with the gain and with the sound path

Auto-scale, auto-move with latency. AVG curves can be displayed for any aperture

Gain: The total gain is 110dB, with 0.1dB, 1dB, 2dB, 6dB step values, and the unique automatic gain adjustment and scanning gain function make the flaw detection fast and accurate

AWS D1.1: The American Welding Institute standard that provides a dynamic reflector "defect rating" for a variety of AWS weld inspection applications. It can avoid manual calculations and improve detection efficiency

Crack bathymetry: Automatically measure and calculate crack depth using endpoint diffraction waves

Door Spread: Amplify echo details for easy echo analysis

Continuous recording: Record, store, and play back waveforms in real time

Waveform Freezing: Freezes the waveform displayed on the screen for easy defect analysis

Echo coding: display the 1~6 echo display area in different colors, better distinguish the primary wave and the secondary wave, and facilitate the judgment of the defect location

Ordinary B-scan: real-time scanning, cross-sectional display, making the detection results more intuitive

MUT500S

MUT500S