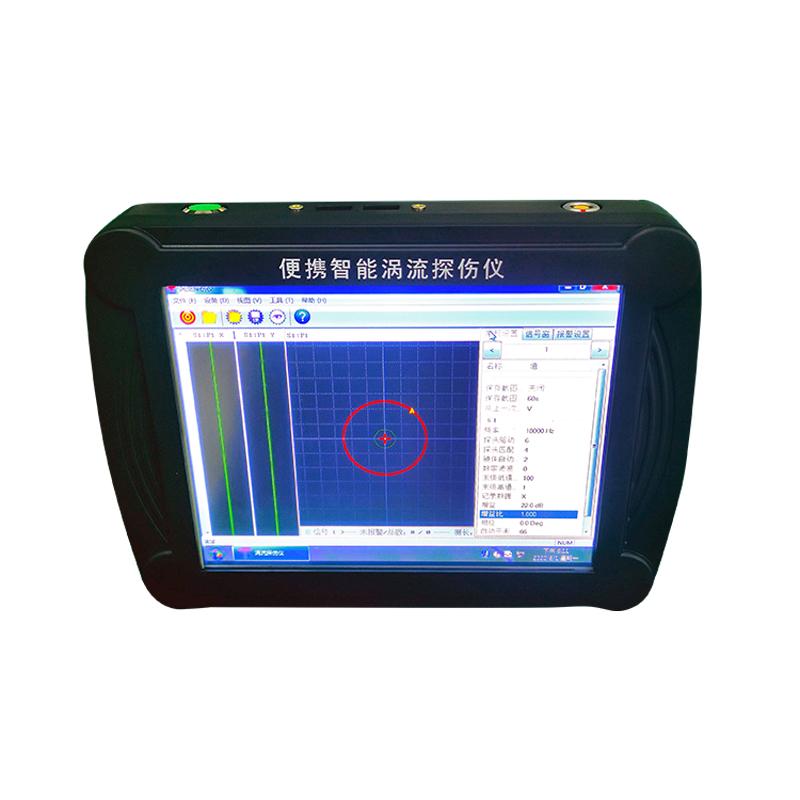

MITECH portable eddy current Flaw Detector MET802 detection channels 2 (expandable to 8)

mitech MET802 Portable eddy current Flaw DetectorSPEC

mitech MET802 Portable eddy current Flaw DetectorDetails

mitech MET802 Portable eddy current Flaw DetectorPacking list

- SKU

- NB049565

- detection range

- 0-5mm

- detection channel

- 1 (can be expanded to 8)

- number of independent detection frequencies

- single frequency

- frequency range

- 10Hz-16MHz, step 1KHz

- Crazing detection Accuracy

- Length × width × depth 3mm × 0.1mm × 0.1mm (using a flat probe to detect steel test blocks)

- Pipe detection Accuracy

- 0.3Mm through hole up to 8db (20mm inner penetration probe) copper pipe

- Gain Range

- 0.0-99, step: 0.1/0/1 dB

- Phase swirling/spinning

- 0-359 ° continuously adjustable, step 1/5/10 Deg

- signal-to-noise ratio

- ≥10dB

- Gain ratio

- (Y/X):0.1-10.0

- probe drive

- January 8

- Linear dispersion

- equivalent amplitude

- digital filtering

- Low-pass: 0Hz-2000Hz; Qualcomm: 0Hz-2000Hz

- number of filter points

- 0-1024

- broadband

- 10Hz-16MHz

- A/D rate

- 12bit 80M

- Automatic equilibrating

- Digital electronic equilibrate

- display mode

- Impedance, Time Base, Circular Hole, Cartesian Coordinates, Polar Coordinates

- scanning speed

- Level 1-1000

- Automatic equilibrating

- Digital electronic equilibrate

- Hardware real-time sampling

- 10-Bit AD converter, sampling speed 160MHz

- Alarm mode

- Real-time alarm

- Alarm window

- Fan, Cube

- Window adjustment

- Levels 1 to 12

- storage type

- 64G hard disk

- test data

- More than 10,000 groups

- detection parameter

- More than 10,000 groups

- display characteristics

- 6- and 8-inch color TFT-LCD LCD display with resolution resolution 1024X760

- standby time

- 8h

- interface

- LEMO-6 DB-15

- Magnetic memory sensitivity

- 5Gs

- Appearance size

- 230 mm × 180 mm ×90 mm

- Machine Weight

- 1.8kg

Product Overview

MET series portable eddy current flaw Detector, also known as digital electromagnetic Detector, it is based on the principle of electromagnetic induction, can detect various metal workpiece surface or near-surface defects at high speed, it adopts advanced digital electronic technology, eddy current technology and microprocessor technology design, the selection of 6-inch and 8-inch TFT LCD touch screen, can clearly display the detection data, the product set computer function in one, high sensitivity, stable performance, multi-channel simultaneous detection, intelligent data analysis, can be equipped with intelligent probe, The probe can also be customized according to customer needs, with a variety of practical functions such as extended magnetic memory, coating thickness measurement, conductivity measurement, etc. It is widely used in the non-destructive testing of various metal pipes, rods, auto parts, bearings, oil casings, oil control rods, annular metal parts, etc., as well as scientific research tests in colleges and universities, and is a professional precision testing instrument necessary to improve production efficiency and save production costs.

Functional use

High-speed non-destructive testing of various metal pipes, rods and wires (a complete set of non-destructive testing solutions can be customized according to user needs);

quality control links in the manufacturing of metal parts such as bearings, rings, and auto parts;

Colleges and universities, scientific research and experiments, etc.

Operating Principle

Eddy current testing technology is based on the principle of electromagnetic induction, which loads an excitation signal into the probe coil, and when the probe approaches the metal surface, the alternating magnetic field around the coil generates an induced current on the metal surface. For flat metals, the direction of the induced current is a concentric circle of coils, shaped like a vortex, which is called an eddy current. The magnitude, phase and flow pattern of eddy currents are affected by the conductivity of the specimen. Eddy currents also generate a magnetic field, which in turn changes the impedance of the detection coil.

Therefore, when there is a defect on the surface or near the surface of the conductor or the measured metal material changes, the strength and distribution of the eddy current will be affected and cause changes, which will cause changes in the Voltage and impedance of the detection coil.

Operating Conditions

Operating temperature: 0°C-+45°C;

Storage temperature: -20°C-+50°C;

Relative Humidity: ≤85%;

There is no strong vibration, no strong magnetic field, no corrosive medium and no serious dust in the surrounding environment.

Instrument features:

It is widely used in nuclear power, military industry, petrochemical industry, metallurgy, university teaching, machinery manufacturing and other fields;

Modular and exquisite design, small size, light weight, easy to carry, can be customized according to customer needs;

It has a 10Hz-10MHz test frequency range, which can meet the detection requirements of a variety of different metals;

It adopts 5.7-inch color TFT-LCD LCD liquid crystal display, menu-type design, easy operation and intuitive display;

One-button switch of multiple modes, more convenient operation, can quickly detect the surface defects of various metal workpieces;

It has the functions of customizable magnetic memory, coating thickness measurement, conductivity measurement, etc.;

Equipped with a large-capacity rechargeable battery, it can meet the needs of long-term outdoor work, and can also be directly connected to a 220V power supply.

It is compatible with various types of probes, and can flexibly customize probes such as internal penetration, external penetration, plane, point type, weld, and fan;

It can realize multi-channel and multi-frequency simultaneous online detection, and can realize limited frequency mixing, with high detection efficiency and high sensitivity;

Using eddy current impedance plane and time-based scanning display technology, eddy current signals can be displayed in real time on the same screen and multiple windows.

The Chinese and English versions can be switched with one key, automatic and manual amplitude and phase adjustment, and the digital and analog electronic balance can be quickly realized;

Real-time alarm output, a variety of alarm window modes, non-equal amplitude, asymmetrical phase alarm area setting;

Professional "digital filtering" is used to effectively suppress interference signals and ensure the accuracy and stability of detection;

It can store a large number of various detection programs and data, with signal acquisition, reading, transmission, analysis, storage, playback and other full-process intelligent processing functions, and can be connected to the printer to print out the file and store the management;

Comply with ASME, GB/T, YB, EN, JIG, API-5L, API-5CL, MH/T and other relevant domestic and foreign standards.

MET802

MET802