MITECH MRT10-S Wire rope Flaw Detector

mitech MRT10-S Wire rope Flaw DetectorSPEC

mitech MRT10-S Wire rope Flaw DetectorDetails

mitech MRT10-S Wire rope Flaw DetectorPacking list

- SKU

- NB049590

- detection range

- 1.5-300 mm (Note: The user should select the corresponding Sensors model according to the diameter of the wire rope to be inspected, and the detection range of different Sensors is different)

- detection efficiency

- 0.0-6 m/s (relative speed of sensor and wire rope)

- Optimum detection efficiency

- 0.3 -1.5 m/s

- allowed clearance

- 0-15Mm (allowable clearance between guide sleeve and wire rope)

- optimal clearance

- 2 -6 mm

- Qualitative Accuracy of broken wire

- 99.99%

- Broken wire error

- One or one equivalent root misjudgment is allowed

- Single centralized broken wire number error-free quantitative detection

- More than 100 times Accuracy rate ≥ 92%

- Sensitivity error

- ±0.055%

- Accuracy error of indication

- ±0.2%

- An indication of length error

- ±0.2%

- Power Supply

- Computer battery powered by 5V

- Sensors Weight

- Common specification < 10kg

Product Overview

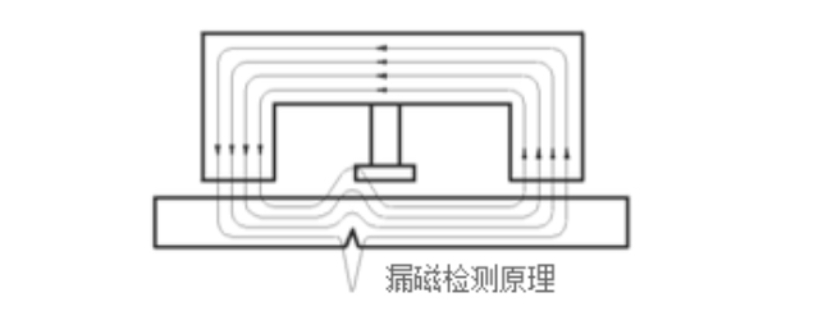

Based on the principle of magnetic flux leakage, the MRT10-S wire rope flaw Detector can detect defects such as broken wire, rust and wear inside and outside the wire rope in real time, and can calculate the quantitative value of the change of metal cross-sectional area, and can generate a diagnostic report in accordance with the current standards and procedures. The hardware part adopts the international advanced MRT magnetic sensor, cooperates with the functional data acquisition module to work, and directly stores the data into the computer through RS232 (or USB) bus drive; The software part is based on the principle of wavelet transform analysis, which can realize the functions of data collection, control, analysis, display and storage: with the help of a unique dynamic continuous tracking method, it can continuously and dynamically observe the changes of data signals, display the detection results in real time, send out alarm signals in real time, and have automatic evaluation functions. The instrument is convenient, simple to operate, high detection accuracy, good repeatability, accurate damage positioning, and is widely used in various lifting machinery, coal mine hoists, oilfield mining machines, elevators, cableways, port machinery, cable bridges, mines, mines, oil wells, docks, ships, military industry, water conservancy, electric power, railways, construction and other industries used in wire rope breakage and wear detection.

Features:

The application of virtual instrument technology, the software replaces the traditional instrument, and the computer directly samples and processes, and the results are accurate and repeatable. 、

Electromagnetic qualitative, quantitative, positioning, online non-destructive detection of wire rope internal and external wire breakage, corrosion, damage, metal cross-sectional area change, loose strands, wire jumping, deformation, material abnormality and other defects.

According to the provisions of the National Metrology Law and the National Safety Production Law, each instrument is inspected by the national metrology agency according to the American ASTM1571 standards and the Shanghai Q/NYNAY01 enterprise standards, and the test report is issued to obtain the legal qualification.

The application of advanced MRT magnetic sensors at home and abroad and combined with the acquisition module independently developed by Mattel, through RS232 (or USB) bus drive, directly store data into the computer.

High-strength magnetic steel excitation, combined with the principle of magnetic flux leakage and magnetic flux change, realizes the comprehensive detection of cracks, rust and rod damage.

Leak-free detection with display wide-angle Hall elements.

The guide sleeve in the sensor floats and is centered, and the collected signal is stable.

The software can realize the functions of data acquisition and control, data analysis, data display and data storage.

Realize AD analog-to-digital conversion, wavelet transformation, noise elimination and other powerful functions.

With the characteristics of visualization, it can continuously and dynamically observe the changes of the data signal and display the results in real time.

When the defect feedback signal exceeds the limit, it will immediately sound and light alarm, humanized design, practical and reliable.

The automatic evaluation function allows for quick and easy automatic analysis of results.

The manual analysis function ensures the accuracy of the results and avoids missed detection and multiple detections.

Local defects show the percentage of the cross-section to the total cross-sectional area.

The inspection waveform can be printed in real time.

The results of the analysis and evaluation of the raw data are generated in Word format and automatically entered.

The instrument is easy to operate and can be used in 10 minutes.

Operating Principle

The working principle of the MRT10-S is that when the wire rope passes through the sensor quickly, the magnet in the sensor magnetizes the wire rope in the axial depth and reaches saturation. The magnetic signal diffused to the space is accumulated by the concentrating ring, and is converted into a Voltage change value by the array wide-angle Hall element group, and the analog-to-digital conversion is carried out through the AD interface, and the digital signal is compressed and then input into the PC. Real-time decompression processing by software based on 3D mathematical model. The changes in the internal and external wire breakage, corrosion, damage and metal cross-sectional area of the wire rope are displayed with clear quantitative values, and the diagnostic evaluation report of the safety and service life of the wire rope is proposed according to the current standard.

MRT10-S

MRT10-S