Factory direct NBC-XF200 extrusion slot-die flat coating machine

Factory NBC-XF200 Extrusion slot-die flat coating machineSPEC

Factory NBC-XF200 Extrusion slot-die flat coating machineDetails

Factory NBC-XF200 Extrusion slot-die flat coating machinePacking list

- SKU

- NB050302

- Spreader size

- Max.L200mm*W300mm

- substrate size

- L430mm*W320mm

- Mechanical speed

- Traverse speed 1-200mm/s

- Film thickness

- Max:5mm

- Feed Capacity

- Stainless steel syringe (Max: 60ml)

- Feeding speed

- 0.05-5 mm/s (barrel piston speed) optional

- Installation size

- L740mm*W444mm*H425mm

- Film thickness

- 40mm

- Heating range

- Room temperature -200 ℃

- Weight

- About 90Kg

- Accuracy

- ±2um

- viscosity

- 100-7000mPas

- bottom

- Heating range 0-200 ℃, temperature control Accuracy +/- 1 ℃

- gap

- 10Um-10mm adjustable, adjustment Accuracy 1um

- Coating method

- extrusion coating

- Lip height

- 0~5Mm, adjustable

- Adjustment Accuracy

- A. Digital dial: 1um

- Coating Accuracy

- +/- 2μm (reference value depends on slurry characteristics)

- Die head model

- TG-C200

- Die head material

- SUS630

- Die Accuracy

- Lip straightness ≤ 3μm

- cavity Volume

- 8ml

- gasket width

- Opening width Max. 200mm

- Film thickness

- 30/50/70/100/200um (Film thickness is selected according to solution viscosity)

- Power Supply

- Single Phase AC110 - 220V +/- 10%, Frequency 50/60Hz, Power 300W

Product Introduction

TG-TB extrusion slit flat coater is a equipment applied to the surface coating of sheet substrates, which can be used for scraper coating, wire rod coating, slit coating, four-sided film maker coating, and other coating processes. It is mainly used in laboratory research and development, and can work in the glove box. This equipment is mainly used for the surface coating of chip substrates in the fields of various types of glue, lithium battery substrates, OLED, solar photovoltaic films and polymer conductive films.

Functional features:

A variety of coating processes are adopted, with high coating accuracy and good consistency.

The coating window is wide, and the viscosity is more applicable.

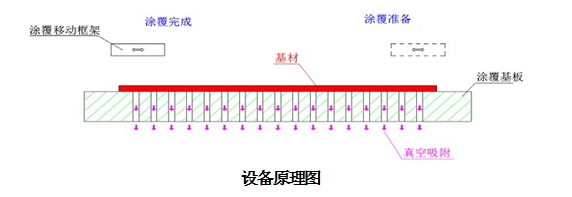

The coating substrate can be equipped with an optional vacuum suction plate and a built-in Vacuum Pump, so that the substrate can be evenly adsorbed on the surface of the coating board.

The device can be used in an argon atmosphere inside the glove box.

Touch screen operation, equipment parameter adjustment, storage and control are convenient and fast.

A variety of applicators are available.

Process introduction

Brief description of the equipment principle: Different applicators are installed on the coating mobile frame, and the frame drives the applicator to evenly coat the slurry on the substrate.

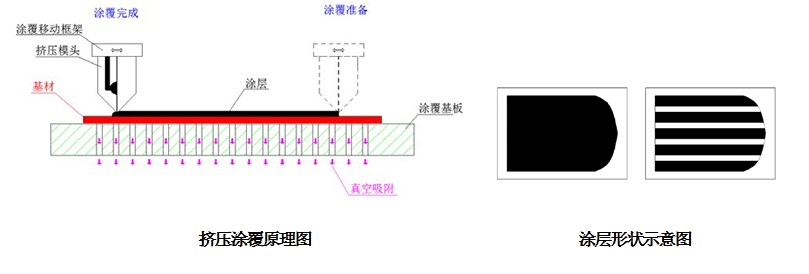

Extrusion coating

Brief description of the process: After the coating enters the coating die, it flows out at the outlet through pressure distribution and is coated on the surface of the substrate to form the target coating. The coating thickness and size are affected by the feeding speed and coating speed, and the coating accuracy is affected by many factors such as die accuracy, die adjustment accuracy, flatness of the coating plate, movement speed accuracy, feeding accuracy and coating characteristics

NBC-XF200

NBC-XF200