Factory direct sales Rgdjy-02/350dcpro immersion coil Automatic Film Applicator wet film thickness 0.005-3mm Continuous experimental Automatic Film Applicator

Factory Rgdjy-02/350dcpro Automatic Film ApplicatorSPEC

Factory Rgdjy-02/350dcpro Automatic Film ApplicatorDetails

Factory Rgdjy-02/350dcpro Automatic Film ApplicatorPacking list

- SKU

- NB050650

- Spreader process

- Unwinding and scraping → Extruding Dampener Roller and Gel Tank Cleaning 1 → Cleaning 2-Air Knife → Oven 2 meters → Deviation correction → Winding

- Effective Spreader Width

- Max.Φ350mm

- coating method

- Adjustable scratch coating

- Cutting head type

- Film thickness adjustable

- Indication display

- digital display

- wet film thickness

- 0.005-3mm

- Regulator Graduation

- 0.001mm

- Spreader accuracy

- ±5%

- coating speed

- 1-10M/min (adjustable)

- unwinding method

- Inflatable shaft unwinding

- winding method

- Inflatable shaft winding

- Outer diameter of winding air expansion shaft

- 3-Inch expansion shaft, load-bearing 50KG

- maximum discharge

- Max.Φ350mm

- maximum charge

- Max.Φ350mm

- Drying temperature range

- RT+~200℃

- Temperature control accuracy

- ±3℃

- Heating method

- hot air circulation

- Oven length

- 1M/section * 1

- Total length of drying tunnel

- 2m

- Drying power

- 1KW/section

- Tension control range

- Automatic constant tension (1-10N)

- Tension control accuracy

- ±0.5N

- Motor type

- Servo motor

- control mode

- PLC + Touchscreen

- Human Machine Interface

- Color Touchscreen

- tension control

- automatic

- correction control

- automatic

- Film thickness control

- manual

- soak

- With soaking function

- soaking size

- Soak 1 meter

- gas source

- 0.5~ 0.8MPa compressed air

- Applicable coil type

- Plastic film, metal foil, paper, non-woven fabric, etc

- Spreader type

- Water-based paints, solar-based paints, UV coatings, etc

- application field

- Encasement, electronics, construction, automotive, medical, etc

- Operating Environment Temperature

- 10℃ ~ 40℃

- Operating Environment Humidity

- 30~90%RH

- power requirements

- 380V, 50Hz, three-phase five-wire system

- total power consumption

- 45KW (subject to actual customization)

- dimensions

- About 6000mm (total length of the frame 3m + 2 meters oven + 1 meter soaking) * 1200mm * 1600mm (subject to actual customization)

- safety protection

- emergency stop button

Product Introduction

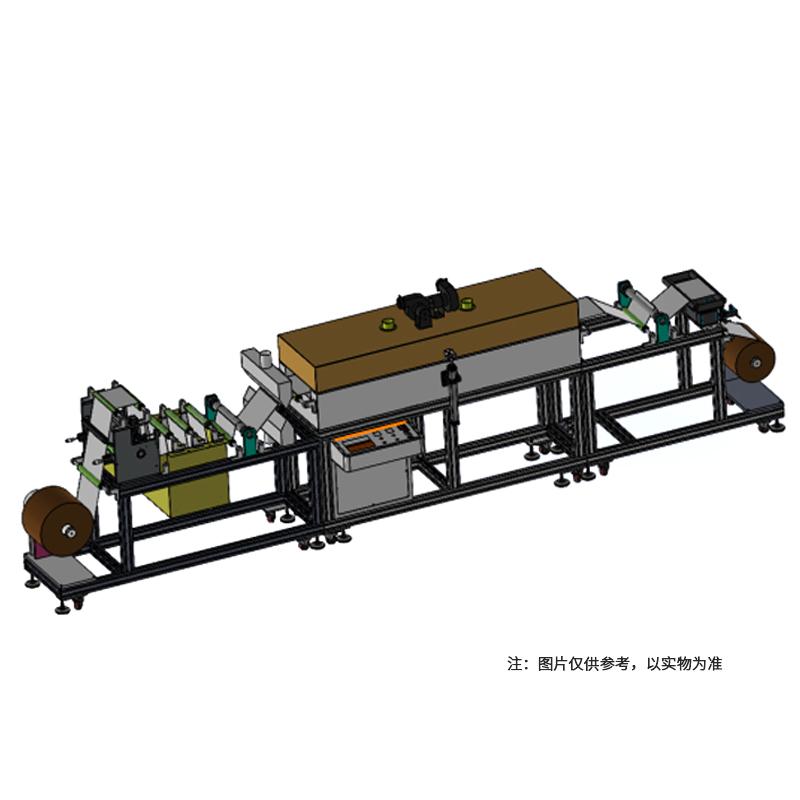

RGDJY-02/350DCPRO coil scraper coating machine is a continuous experimental film coating machine with unwinding, scraping, soaking, drying, and winding functions, with a wet film thickness of 0.005-3mm, suitable for hot melt adhesives, self-adhesives, plasters, etc.

Product structure

The machine is composed of a body, a gluing width adjustment device, a discharge frame, a gluing roller set, a thickness adjustment dial indicator, a transmission platform, a traction roller set, and a transmission mechanism.

1. Body: The body of the equipment is all composed of aluminum alloy + high electrostatic spraying plate.

2. Gluing width adjustment device: The width adjustment device is composed of food-grade plastic and movable braces.

3. Discharge rack: The machine is equipped with two discharge racks, when the two materials are misaligned in the process of lamination, the correction device automatically adjusts to make the rack move left and right to achieve the effect of aligning the two materials.

4. Gluing roller group: The gluing roller group is made of double drum precision machined parts, and the transmission is smooth.

6. Thickness adjustment percentage table: the adjustment of the coating thickness required when gluing. The thickness of the glue coating can be adjusted by rotating the left and right handwheels on the gluing roller frame clockwise or counterclockwise, and the specific thickness is determined according to the dial indicator.

7. Transmission platform: The transmission platform is made of stainless steel, and its main function is to smoothly transmit the substrate to the next process after connecting the gluing.

8. Traction roller group: the substrate is pulled by hand between the upper and lower rollers of the traction roller, the handwheel on the frame is tightened to make the traction roller, the rubber ring of the upper roller is in contact with the lower roller, and the traction roller group pulls the substrate over through the power transmission to complete the coating work.

Main parameters of equipment work

1. Sequence of requirements: double unwinding 350mm →scraping→ soaking into a film→ into the oven, drying 2 meters → tension controller→ edge correction → winding

2. Equipment production: unwinding → tension controller→ overlay coating (rubber rollers are installed on the large overlay rollers to squeeze water), →enter the sink (sink with circulating filtered water source), blow dry → air knife (air knife can adjust the angle), enter the oven→ tension control→ correct edges→ winding→ winding

Functional features:

Substrate tension control, belt stability;

main drive servo drive, speed can be set;

Hot air oven;

PLC control, HMI operation, convenient and easy to use;

Process introduction

1. The equipment adjusts the unwinding tension by controlling the torque of the unwinding shaft, and adjusts the unwinding tension by controlling the torque of the rewinding shaft, and the rotation line speed of the main drive steel roller is

The main drive speed realizes belt control.

The drying oven uses electrically heated air, and the hot air heats and dries the substrate.

Rgdjy-02/350dcpro

Rgdjy-02/350dcpro