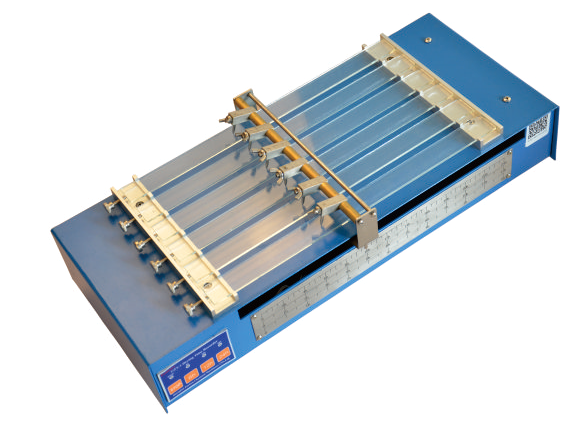

PUSHEN GZY-I Drying Time Recorder

Pushen GZY-I Drying Time RecorderSPEC

Pushen GZY-I Drying Time RecorderDetails

Pushen GZY-I Drying Time RecorderPacking list

- SKU

- NB005828

- Number of strokes

- 6-Pin

- Scribing needle specification

- Φ1mm

- Load Weight

- 11g

- itinerary

- 300mm

- trajectory period

- 6/12/24h

- Motor Power

- 20W

- Dimension

- 490*220*130mm

- Shipment Weight

- 10kg

Introduction to the GZY-I Drying Time Recorder

The drying time of the paint is measured in a straight line with up to 6 simultaneous test points.

Six strip bars with hemispherical contacts, mounted on the carriage.

The strip bar is driven by the carriage, contacts the new coating layer, starts from one end, and moves longitudinally on the specimen.

The distance traveled can be measured by a scale on the edge of the instrument, which corresponds to the various drying stages of the observation trajectory.

The coating is pre-applied to a 25 mm wide and 300 mm long glass strip and applied using a cube applicator.

The principle of the drying time Recorder is based on a mathematical formula:

Distance = speed × time.

A spherical contact is placed in the coating to be tested, and the drying time Recorder starts moving the ball at a pre-set speed.

When the coating dries, the traces left by the spherical tip in the coating indicate the various stages of the curing process.

Meets standards

ASTM D5895 Standard Test Method for Measuring Film Generation Time During Drying or Vulcanization of Organic Coatings for Mechanical Recorders.

Optional

Square Film Applicators and coating strips are sold separately and are not included in the machine.

GZY-I

GZY-I