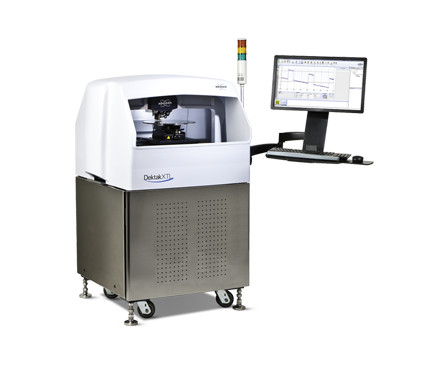

Bruker Dektak XTL Probe Profile Gauge SystemSPEC

Bruker Dektak XTL Probe Profile Gauge SystemDetails

Bruker Dektak XTL Probe Profile Gauge SystemPacking list

- SKU

- NB006286

- Dimensions

- 978*954*1714mm

- Operating Conditions

- Temperature range: 20 ° to 25 ℃ (68 ° to 77 ° F) working interval; Humidity range: ≤ 80%, no condensation

- Software options:

- Automatic graphic recognition; advanced software interface

- Vibration isolation

- High performance vibration isolation, passive pneumatic air isolator

- scan length

- 300mm

- Number of data points covered per scan

- 120,000, maximum

- Maximum sample thickness

- 50mm

- Maximum wafer size

- 300mm

- Maximum sample Volume

- 350mm

- Step height reproducibility

- < 5 Angstroms @0.1 micron height master standard, 1 standard deviation

- vertical range

- 1mm

- Vertical resolution

- Maximum 1 Angstrom (@6.55 μm range)

- Input Power

- 100 to 240VAC, 50 to 60Hz

- Weight

- 272kg (600lbs)

Dektak XTL probe profilometer system

Under strict quality assurance and quality control, 300 mm good performance detection is obtained

Bruker's new Dektak XTL™ probe profiler system accommodates samples up to 350 mm x 350 mm, bringing Dektak's® excellent repeatability and reproducibility to large-format wafer and panel manufacturing. The Dektak XTL's integrated gas isolation and convenient interlocking device enable the instrument to operate in a fully enclosed operating environment, making it ideal for today's demanding production environments.

Its dual-camera setup enhances the sense of space, and its high level of automation maximizes throughput. Bruker's Vision64® production interface with pattern recognition meets the user's needs and makes data acquisition an autonomous and repeatable process with minimal operator variation.

The Dektak XTL has been fully optimized for continuous production time and maximum throughput for process development and quality assurance and quality control applications, and has been designed to be the industry's easiest to use probe profiler.

Dektak XTL Features

Bruker's dual-camera control system

1. Lock into focus faster by tapping on the live video

2. Quickly locate the sample by selecting two points in the live video (auto-rotate to make the line horizontal)

3. Simplify measurement setup by tapping the scan start and end locations in the live video (tutorial)

Reliable automation setup and operation

1. With the help of a 300 mm automatically coded XY table and 360 degree rotation capability, precise programming control of unlimited measurement positions.

2. Use the Vision64-bit product software with pattern recognition function to reduce the positioning deviation in use as much as possible

3. Compile custom user prompts and other metadata into your solution and store it in a database

Convenient analysis and data acquisition

1. The fast analyzer supports most of the commonly used analysis methods, and can easily automate the analysis procedure

2. Focus the analysis on the features of interest on complex samples with step detection

3. Simplify data analysis by giving each measurement point a unique name and automatically recording it to a database

4.Dektak's legendary performance in large sample manufacturing

The industry's best automated analysis software

The new software features make the Dektak XTL the most powerful and easy-to-use probe profiler on the market. The system uses Vision64 software, which is fully compatible with Bruker's optical profilers. Vision64 software enables measurements of any position of the sample, 3D mapping, and highly customized characterization methods with hundreds of built-in analysis tools. Shapes such as radius of curvature can also be measured using Vision Microform software.

Very good probe detection technology

Pattern recognition minimizes operator error and improves measurement position accuracy. Intuitive data acquisition and 2D and 3D analysis in the same software package. Each system comes with a Vision software license that can be installed on a PC with a Windows 7 operating system, allowing users to create data analysis and reports on their desktops.

With over 40 years of probe expertise and custom software manufacturing experience, Dektak XTL aligns with the rigorous industry roadmap for now and in the future.

The 300 mm high-precision coded XY table provides manufacturers with a reliable tool to meet stringent repeatability and reproducibility requirements. The Dektak dual-camera control system features a top-down camera and a high-magnification side-view camera for enhanced spatial perception, and a click-and-click position on video that allows the operator to quickly adjust the sample to the correct position for quick and easy measurement setup and automated programming. The system's easy-to-use interlocking doors make sample loading and unloading safer and faster. Other hardware features include:

1. Single-arch structure and integrated isolation structure used to achieve extremely low noise levels

2. Probes that can be quickly replaced and automatically calibrated

3. High-precision encoded XY table for accelerated automatic data acquisition

4. N-Lite can be used at the same time as the Soft Touch technology and the 1mm measurement range at low forces, which can be used for fine and high vertical range sample measurements

Key outcomes for large-format applications

With its unique combination of superior performance and ease of use, Dektak XTL has become the new research standard for quality assurance/quality control for industrial thin film deposition monitoring in the touch panel, solar panel, flat panel display and semiconductor industries.

Wafer Applications:

The step height of the deposited film (metal, organic).

The step height of the resist (soft film material).

Etch rate determination

Chemical mechanical polishing (corrosion, denting, bending)

Large Substrate Applications:

Printed circuit boards (protrusions, step heights)

Window coating

Wafer masks

Wafer chuck coatings

Polishing plate

Glass Substrate & Display Applications:

AMOLED

Step step height measurement developed by LCD screen

Touch panel film thickness measurement

Solar coating film measurements

Films for flexible electronics:

Organic photoDetectors

Organic films printed on film and glass

Touch screen copper trace

Parameters of the probe profilometer system Dektak XTL

Software options: automatic pattern recognition, advanced software interface

Vibration isolation: high-performance vibration isolation, passive pneumatic air isolator

Scan length range: 300mm

Number of data points covered per scan: 120,000, maximum

Maximum sample thickness: 50mm

Maximum wafer size: 300mm

Maximum sample volume: 350 mm

Step Height Reproducibility: <5 Angstroms @ 0.1 μm Height Standard, 1 standard deviation

Vertical range: 1mm

Vertical Resolution: Max 1 angstrom (@6.55μm range)

Input power: 100 to 240VAC, 50 to 60Hz

Temperature range: 20° to 25°C (68° to 77°F) operating range

Humidity range: ≤80%, non-condensing

System Dimensions & Weight: 978 mm (38.5 in) W x 954 mm (37.6 in) D x 1714 mm (67.5 in) H, 272 kg (600 lbs)