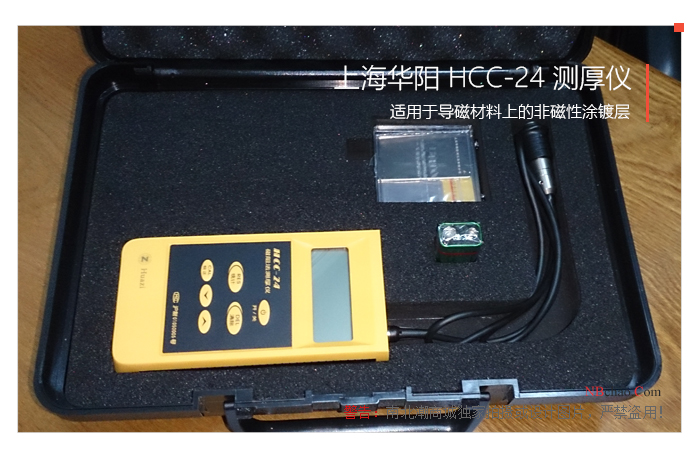

Shanghai HUAYANG HCC-24 Magnetoresistive Thickness Gauge, suitable for nonmagnetic coating platings and paint films on magnetically conductive materials

-

LANDTEK CM8821 Coating Thickness Gauge measurement of non-magnetic conductive coatings on ferromagnetic metal substrates$ 236.00SE

LANDTEK CM8821 Coating Thickness Gauge measurement of non-magnetic conductive coatings on ferromagnetic metal substrates$ 236.00SE -

Leeb210 coated Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields

Leeb210 coated Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields -

LEEB242 (F1) paints Thickness Gauge with external magnetic probe

LEEB242 (F1) paints Thickness Gauge with external magnetic probe -

KAIRDA NDT530 (F1) Galvanized Thickness Gauge with magnetic Induction Probe$ 287.00SE

KAIRDA NDT530 (F1) Galvanized Thickness Gauge with magnetic Induction Probe$ 287.00SE -

Leeb220 Magnetoresistive Thickness Gauge, Non-Magnetic Coating on Magnetic Metal Substrate Film thickness

Leeb220 Magnetoresistive Thickness Gauge, Non-Magnetic Coating on Magnetic Metal Substrate Film thickness

HuaYang HCC-24 Magnetoresistive Thickness GaugeSPEC

HuaYang HCC-24 Magnetoresistive Thickness GaugeDetails

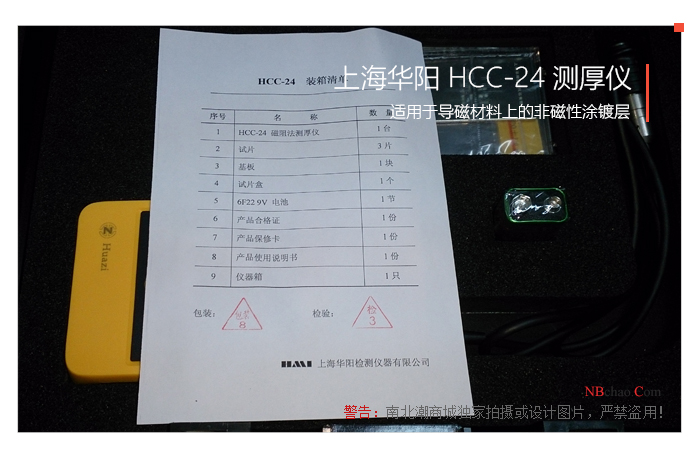

HuaYang HCC-24 Magnetoresistive Thickness GaugePacking list

- SKU

- NB000680

- Measurement principle

- Magnetic Induction

- Measurement range

- 0~1200μm

- margin of error

- ±3%

- Resolution

- 1μm

- Minimum radius of curvature

- 15mm

- probe

- Split F probe

- statistical function

- Measurement Times, MAX Maximum, MIN Minimum, Average

- icon function

- without

- Power Supply

- One 6F22 9V battery

- Standards

- ISO 2178、GB 4956

- Calibrated Certificate

- without

- system language

- Chinese

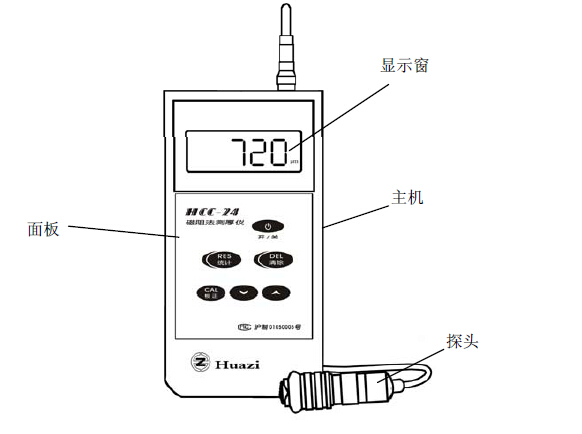

- Display screen

- 4-Bit LCD display

- supporting software

- without

- Machine Weight

- Approx. 250g

- Machine size

- 160*80*30mm

- Minimum measurement surface

- 30*30mm

- Operating temperature

- 0~40℃

Introduction

HCC-24 magnetoresistive Thickness Gauge adopts the principle of electromagnetic induction for measurement, in line with the international standard ISO2178 and the national standard GB/T4956, and can measure the thickness of non-magnetic coating on magnetic permeable materials, such as zinc, chromium, tin coating and paint on the surface of steel materials, and enamel coating. Magnetoresistive Thickness Gauges can judge the uniformity of the coating through multi-point testing, and can measure the average, maximum, minimum, standard deviation, and number of measurements. The HCC-24 Magnetoresistive Thickness Gauge features a wear-resistant, hard metal probe with a spring-guided sleeve probe that can measure on hard or rough surfaces with constant compression and stable sampling values.

Actual picture of the product

Features

1. The HCC-24 Thickness Gauge can quickly and non-destructively measure the thickness of the non-magnetic permeable covering layer on the surface of the magnetic permeable material

2. HCC-24 has the function of mathematical statistics, which can directly display the number of measurements, the average value, the maximum value and the minimum value

3. Spring-loaded bushing probe with wear-resistant hard metal probe

4. It cannot be used in high temperature environment, and the measured ambient temperature is 0~40°C

Meets standards

HCC-24 Magnetoresistive Thickness Gauge Applicable Standards:The international standard is ISO-2178 and the national standard is GB-4956

Certificate of Authorization for Sales

- 1HUAYANG HCC-24 Magnetoresistive Thickness Gauge Operation Instructions

- 2Reasons for measurement deviation of Coating Thickness Gauge

- 3Detailed comparison of 4 Coating Thickness Gauges in Huayang

南北潮

- 1QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 5ISO 2178-2016《Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method》

- 6ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 7ISO 19840-2012《Paints and varnishes Corrosion protection of steel structures by protective paint systems》

- 8ASTM E376-2019《Standard Practice for Measuring Coating Thickness by Magnetic-Field or Eddy Current (Electromagnetic) Testing Methods》

- 9ISO 2808-2019《Paints And Varnishes - Determination Of Film Thickness》

- 10JJG 889-1995《Magnetic Resistance Thiness Gauge》

HCC-24

HCC-24