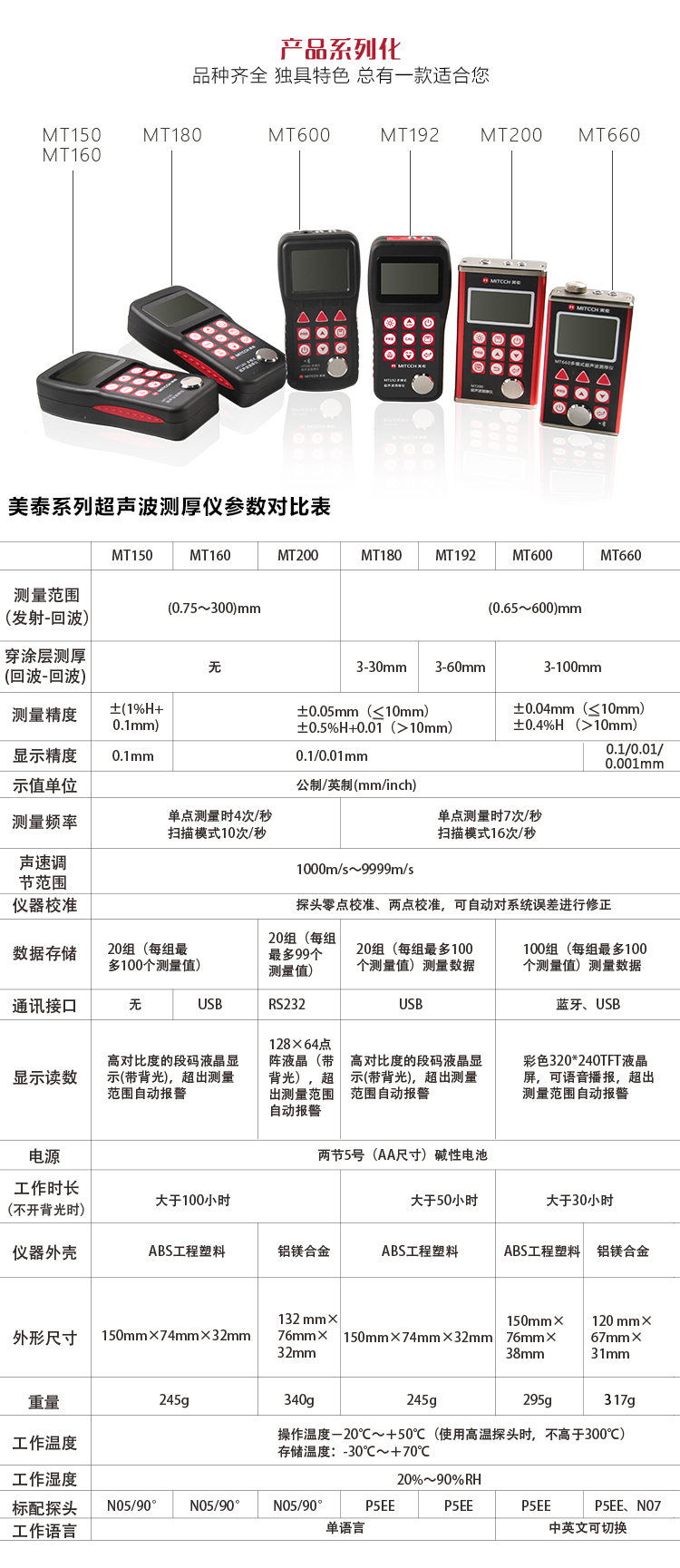

Mattel MT200 High Precision Ultrasonic Thickness Gauge Thickness Range 0.75~ 300mm

mitech MT200 Ultrasonic Thickness GaugeSPEC

mitech MT200 Ultrasonic Thickness GaugeDetails

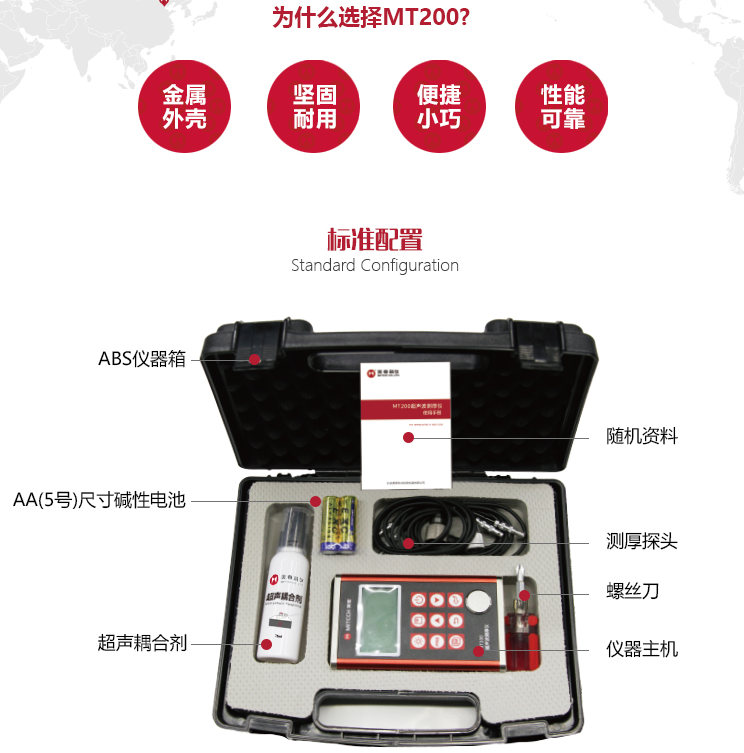

mitech MT200 Ultrasonic Thickness GaugePacking list

- SKU

- NB007624

- Measurement range

- 0.75~300mm

- Probe Frequency

- 2.5~7MHz

- Probe style

- Split probe

- Probe diameter

- Thickness measuring probe NO5Should 10MM, microcrystalline probe N07Should 6MM, high temperature probe HT5Should 12MM, coarse crystal probe N02Should 12MM

- Lower limit of pipe measurement

- Φ15*2mm

- measurement error

- ±0.05mm(≤10mm);(±0.5%H+0.01)mm(>10mm)

- Display resolution

- 0.1Mm/0.01mm (optional)

- unit system

- mm/inch

- Calibration method

- Single point calibrated, two point calibrated

- Measurement mode

- Single point mode, scan mode

- Measurement speed

- Single point measurement 4 times per second, scanning mode 10 times per second

- Storage Capacity

- 20 groups * 99 Measured values

- Speed of sound

- 1000~9999m/s

- Display

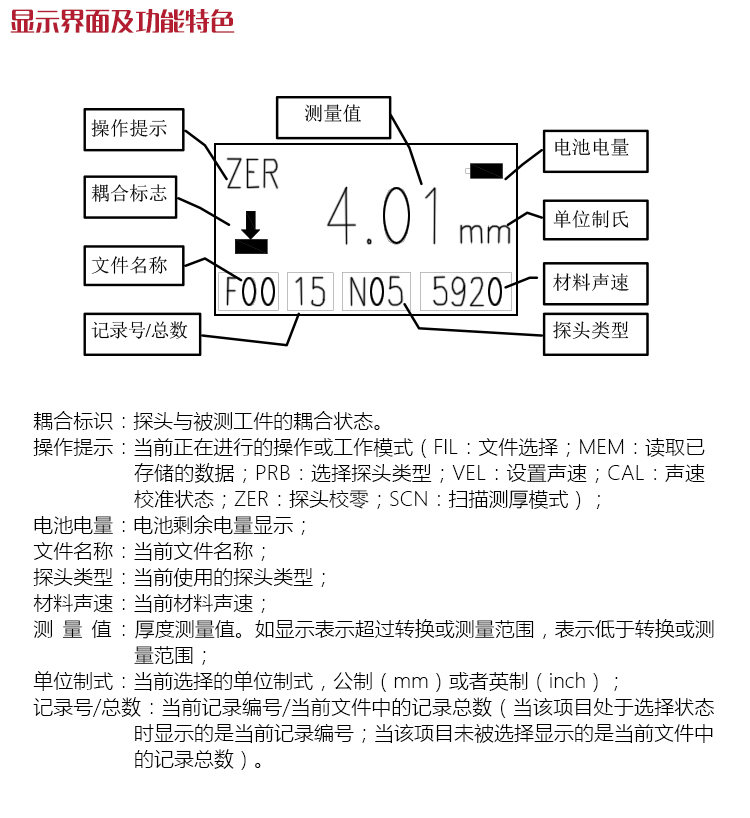

- 128 × 64 Chinese dot matrix liquid crystal display, high luminance EL backlight

- Operating language

- Chinese

- Interface

- RS232

- Application Software

- Yes.

- Environmental temperature

- -20~50℃

- Working Relative Humidity

- ≤90%RH

- Storage temperature

- -30~70℃

- Power Supply

- 3V (2 * AA alkaline battery in series)

- power consumption

- Low power design

- Operating Time

- 1000h

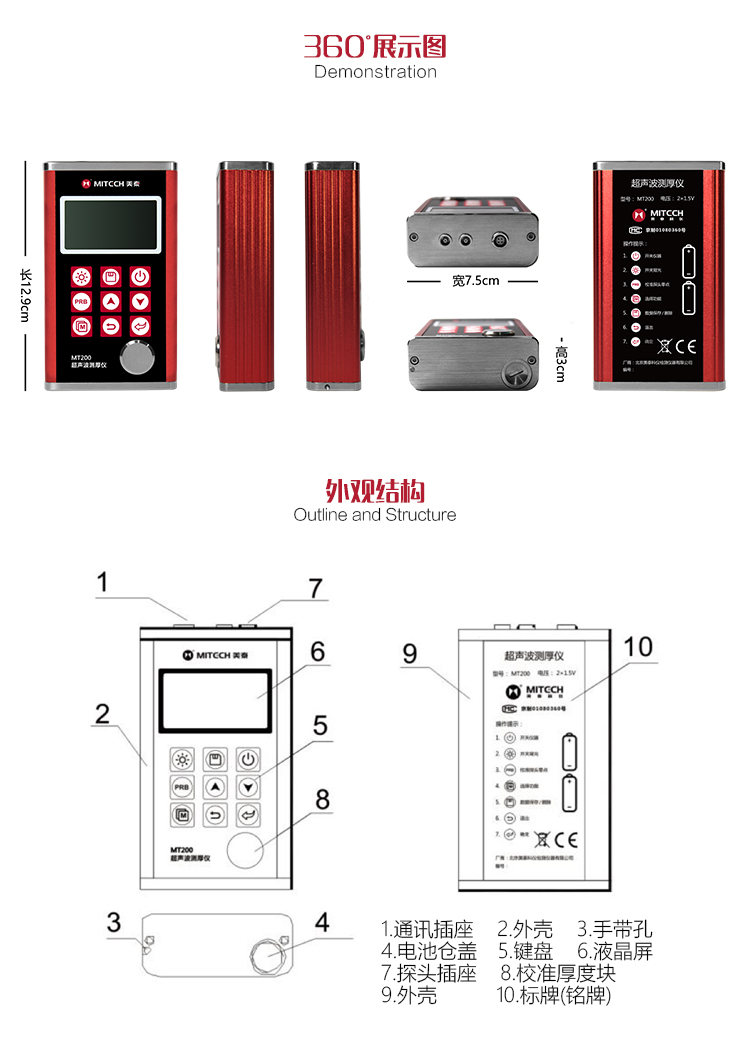

- Host size

- 132*76*32mm

- Weight

- 1.5KG

- Interface

- Connect to computer to print

- Environmental temperature

- -20~50℃

- Working Relative Humidity

- ≤90%RH

- Body material

- Aluminum magnesium alloy

- Storage temperature

- -30~70℃

Overview

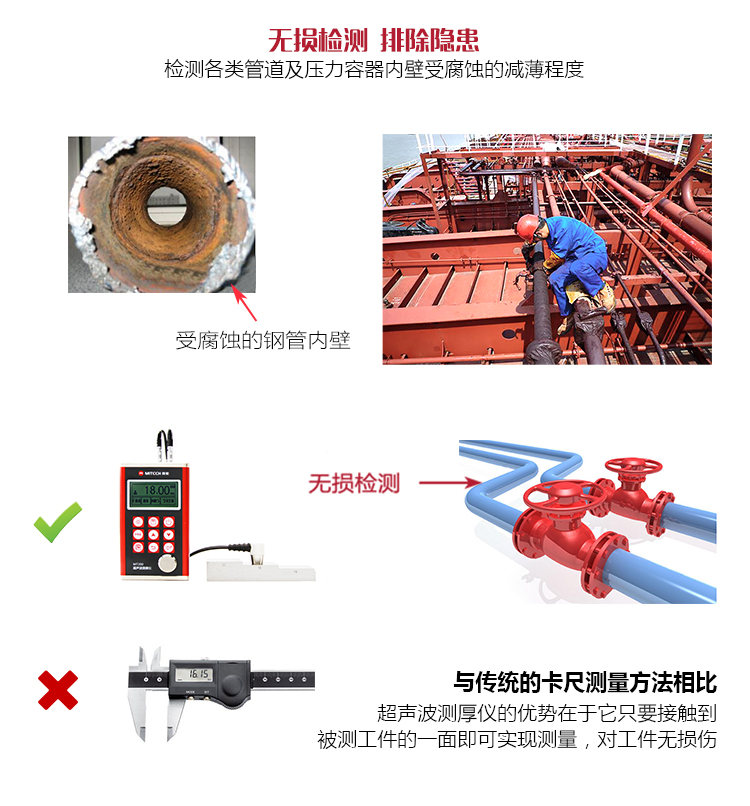

MT200 precision ultrasonic Thickness Gauge, based on the principle of ultrasonic propagation, can measure the thickness of metal, plastic, ceramic, glass and other ultrasonic conductor materials, and can also realize the reverse measurement of the sound velocity of materials. The sealed metal shell is designed to protect against oil and dust in harsh on-site environments. Compared with the traditional measurement method, the advantage of ultrasonic Thickness Gauge is that it only needs to contact one side of the workpiece to be measured can be measured, and its unique non-destructive testing performance provides a good solution for the thickness detection of closed pipes, containers and other limited Operating Conditions, and is widely used in petroleum, chemical, metallurgy, shipbuilding, aviation, aerospace and other fields of production equipment in various pipelines and pressure vessel corrosion thinning monitoring, can also be used for a variety of plates and various processed parts to do accurate measurement.

Functional use

It is suitable for measuring the thickness of metals (e.g. steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, fiberglass, and any other good conductor of ultrasound

It can be equipped with a variety of probes with different frequencies and different element sizes

It has the functions of zero point calibration and two-point calibration of the probe, which can automatically correct the system error

Known thicknesses can be used to backmeasure the speed of sound to improve measurement accuracy

It has two Operating Modes: single-point thickness measurement and scanning thickness measurement

The upper and lower limits of the thickness value can be set in advance, and the automatic alarm will be given when the range is exceeded

It has a coupling status prompt function

Operating Conditions

Ambient temperature: operating temperature -20°C~+50°C

Storage temperature: -30°C~+70°C

Relative Humidity≤90%

There is no strong vibration, no strong magnetic field, no corrosive medium and no serious dust in the surrounding environment

Features

There is a residual battery indication function, which can display the remaining battery power in real time

It has power-saving functions such as automatic sleep and automatic shutdown

With RS232 interface, it can easily and quickly exchange data and set parameters with the PC. It can be connected to a micro printer (manufacturer-specified model) to print a measurement report

It can be equipped with microcomputer software, which has rich functions such as transmitting measurement results, measuring value storage management, statistical analysis of measured values, and printing measurement reports

Small, portable, and highly reliable in a sealed metal enclosure for harsh operating environments, resistant to vibration, shock, and electromagnetic drying

It has the functions of zero point calibration and two-point calibration of the probe, which can automatically correct the system error

Known thicknesses can be used to backmeasure the speed of sound to improve measurement accuracy

It has two Operating Modes: single-point thickness measurement and scanning thickness measurement

The upper and lower limits of the thickness value can be set in advance, and the automatic alarm will be given when the range is exceeded

It has a coupling status prompt function

MT200

MT200