Mattel MT160 Ultrasonic Thickness Gauge Thickness Range 0.75~ 300mm USB Interface

SEmitech MT160 Ultrasonic Thickness GaugeSPEC

mitech MT160 Ultrasonic Thickness GaugeDetails

mitech MT160 Ultrasonic Thickness GaugePacking list

- SKU

- NB007625

- Measuring range

- 0.75~300mm

- Probe frequency

- 2.5~7MHz

- Probe style

- Wired probe

- Probe diameter

- Thickness probe NO5Φ10MM, microcrystalline probe N07Φ6MM, high temperature probe HT5Φ12MM, coarse crystal probe N02Φ12MM

- Lower limit of pipe measurement

- F15 * 2mm

- Measurement error

- ±0.05mm(≤10mm);(±0.5%H+0.01)mm(>10mm)

- Display resolution

- 0.1/0.01mm

- unit system

- mm/inch

- Calibrated

- Zero point calibrated, two point calibrated

- Measurement mode

- Single point mode, scan mode

- Measurement speed

- 4 times per second for single point measurement and 10 times per second for scan mode

- Storage Capacity

- 20 sets * 100 measurements

- Sound speed range

- 1000~9999m/s

- Sound speed storage

- Can store 20 sets (up to 100 measurements each) Film thickness measurement data

- Display

- High contrast segment LCD display, high brightness EL backlight

- Operating language

- Chinese

- Data Interface

- USB1.1, can be connected to PC

- Application software

- Yes.

- Operating Temperature

- -20~50℃

- Relative Humidity

- ≤90%RH

- Storage temperature

- -30~70℃

- Power

- 3V (2 * AA alkalinity battery)

- power consumption

- Low power design

- Operating Time

- 100h

- Host size

- 150*74*32mm

- Weight

- 245g

- Anti-measurement sound speed function

- support

- Operating Temperature

- -20~50℃

- Relative Humidity

- ≤90%RH

- Body material

- ABS engineering plastics

- Storage temperature

- -30~70℃

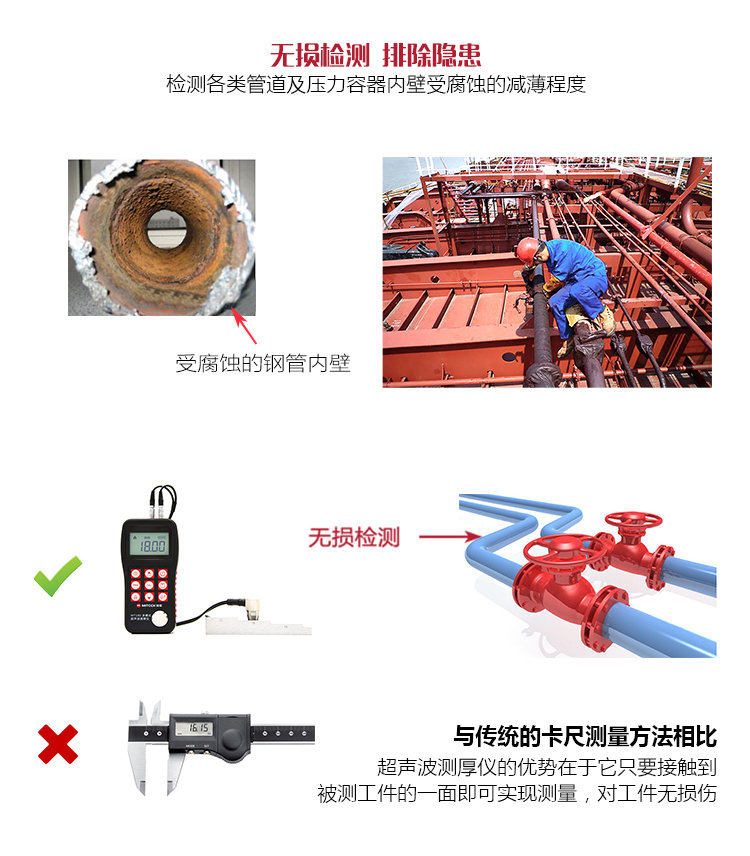

product description

Mitech MT160 Ultrasonic Thickness Gauge, based on the principle of ultrasonic measurement, can measure the thickness of metals, plastics, ceramics, glass and other materials that are good conductors of ultrasonic waves, and can also realize the reverse measurement of the sound velocity of materials. Compared with the traditional measurement method, the advantage of the ultrasonic Thickness Gauge is that it can complete the measurement as long as it touches one side of the workpiece to be measured. It is a good solution and is widely used in the monitoring of the corrosion and thinning degree of various pipelines and pressure vessels in production equipment in the fields of petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace, etc., and can also be used to monitor various plates and various Machined parts for precise measurements.

functional use

Suitable for measuring the thickness of metals (such as steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, glass fibers and any other good conductors of ultrasonic waves

Can be used with a variety of dual-element probes with different frequencies and different chip sizes

With probe zero calibration and two-point calibration functions, it can automatically correct system errors

The known thickness can reverse the sound velocity to improve the measurement accuracy

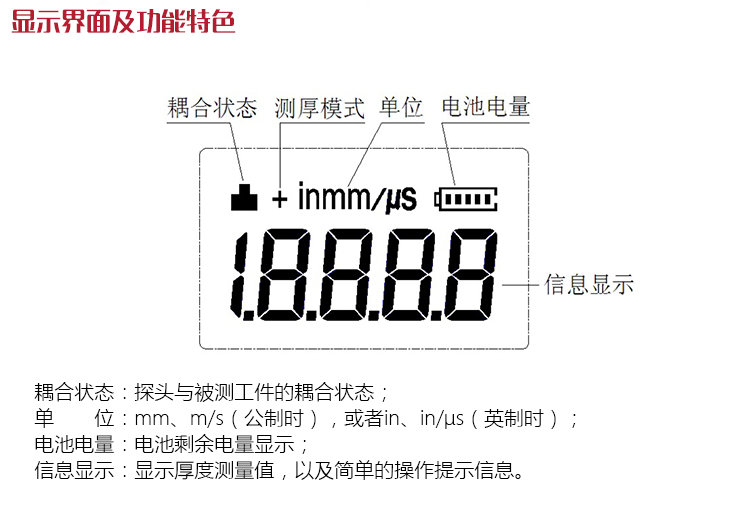

With coupling status prompt function

Operating Conditions

Ambient temperature: operating temperature -20℃~+50℃

Storage temperature: -30℃~+70℃, Relative Humidity ≤90%

The surrounding environment has no strong vibration, no strong magnetic field, no corrosive medium and severe dust

Features

With EL backlight function, it is convenient to use in dimly lit environment

There is a remaining power indicator function, which can display the remaining battery power in real time

Power-saving functions such as automatic sleep and automatic shutdown

Can be used with a variety of dual-element probes with different frequencies and different chip sizes

With probe zero calibration and two-point calibration functions, it can automatically correct system errors

The known thickness can reverse the sound velocity to improve the measurement accuracy

With coupling status prompt function

Small, portable, high reliability, suitable for harsh operating environments, resistant to vibration, shock and electromagnetic interference

- 1JJF 1224-2009《Calibration Specification for Reinforced Concrete Covermeter and Floorslab Thickness Tester》

- 2JJF 1126-2004《Calibration Specification for Ultrasonic Thickness Instruments》

- 3JB/T 11604-2013《Non-destructive testing instruments.Ultrasonic thickness gauge》

- 4ASTM E797-2021《Standard Practice for Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact Method》

- 5GB/T 11344-2008《Non-destructive testing - Practice for measuring thickness by ultrasonic pulse-echo contact method》

- 6JJF 1126-2004《Ultrasonic Thickness Gauge calibrating specification》

- 7ZB N 77001-1989《General Technical Conditions for Ultrasonic Thickness Gauge》

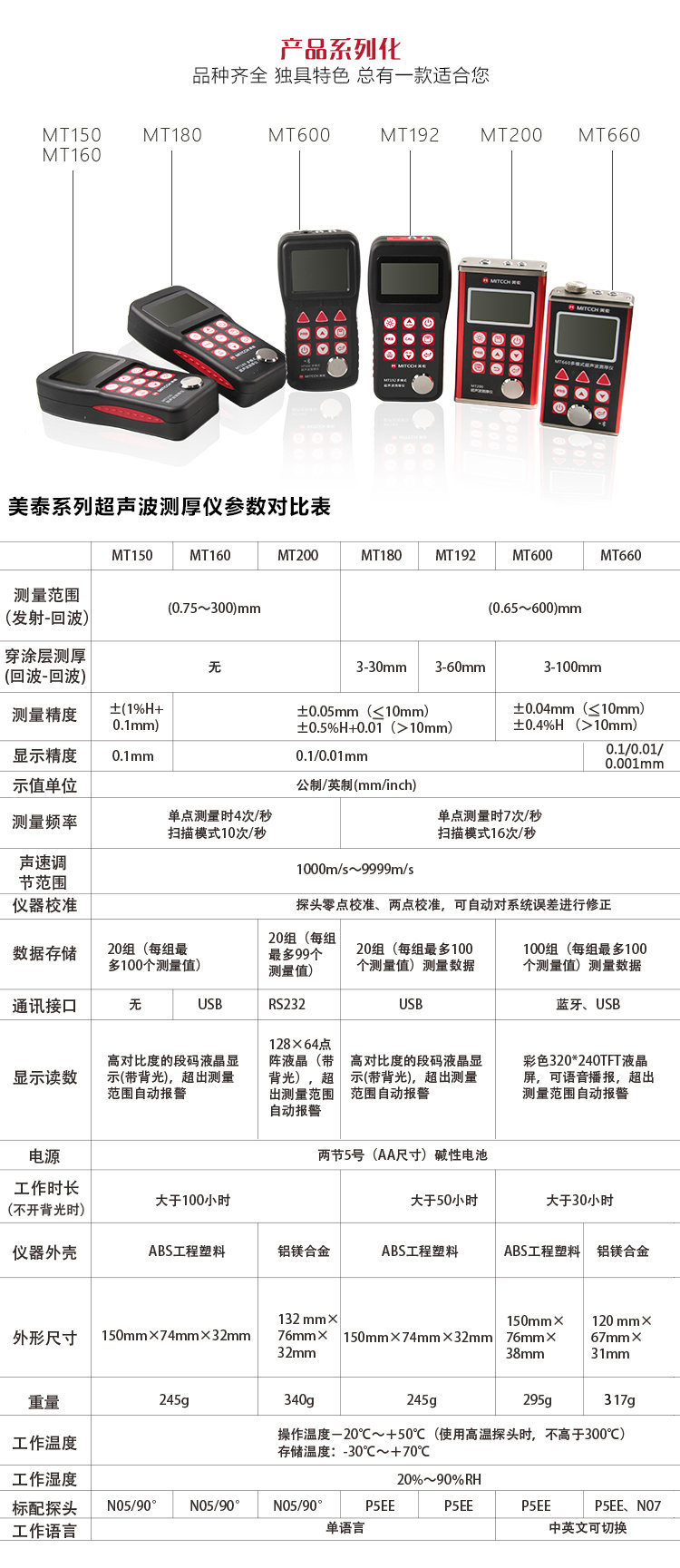

MT160

MT160