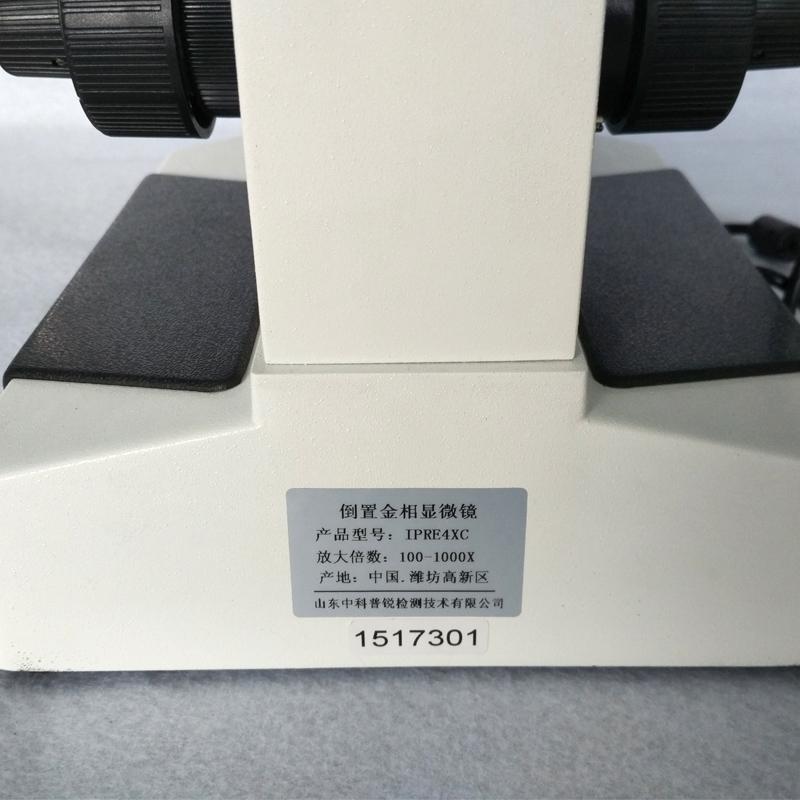

Zhongke Purui IPRE4XC Metallurgical Microscopy trinocular inverted, eyepiece magnification 10X

SEIpre IPRE4XC Metallurgical MicroscopySPEC

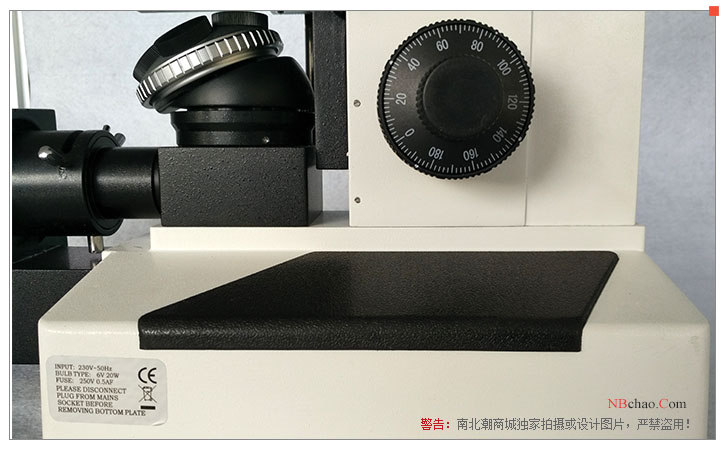

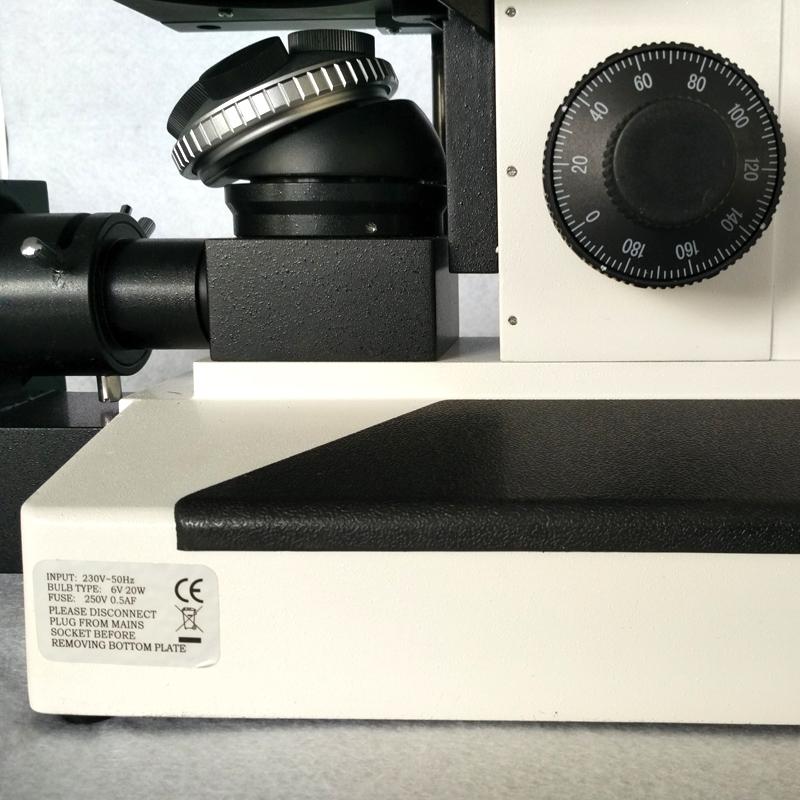

Ipre IPRE4XC Metallurgical MicroscopyDetails

Ipre IPRE4XC Metallurgical MicroscopyPacking list

- SKU

- NB007844

- Trinocular observation head

- Double cylinder tilt is 30 °

- pupil adjustment range

- 55mm~75mm

- eyepiece

- Large field of view eyepiece 10X (field of view Φ16mm); 10X flat field reticle eyepiece (grid value 0.1mm)

- objective lens

- Flat field color difference objective 10X, 25X, 40X, 100X (oil)

- Total magnification

- 100X~1000X

- Focusing system

- Coaxial focus adjustment with coarse fretting, fretting grid value of 2μm, adjustable coarse elastic, with locking and limit device

- converter

- Four holes (ball positioning)

- lighting

- Kulie lighting system, 6V20W tungsten halogen lamp, adjustable brightness

- stage

- 150×180mm

- Movement range

- Vertical 15mm, horizontal 15mm

- Dimensions

- 559mm×195mm×345mm

Introduction

1. The operation is simple, the instrument structure is compact, and the appearance is beautiful and generous;

2. IPRE4XC metallurgical microscope base has a large supporting area, and the curved arm is strong, so that the center of gravity of the instrument is low and stable and reliable. Since the eyepiece and the supporting surface are inclined at 45 degrees, the observation is comfortable;

3. Real-time dynamic observation can be performed on the computer display screen, manual comparison and analysis of the taken metallographic pictures can be carried out, and the required metallographic pictures can also be edited, saved and printed;

4. Measurement graphics can be automatically graded by software.

Application

IPRE4XC metallurgical microscopes are widely used in factories or laboratories to identify the quality of castings; inspect raw materials or analyze metallographic structures after material processing; and conduct research on surface phenomena such as surface spraying. It is an effective method for metallographic analysis of steel, non-ferrous metal materials, castings, and coatings; petrographic analysis of geology; and an effective means for microscopic research on compounds, ceramics, etc. in the industrial field. Instruments are also widely used in fields such as biology, medicine and teaching.

plan

- 1GB/T 44293-2024《Image measurement method for numerical aperture of microscopic objective》

- 2GB/T 43846.1-2024《Microscopes—Designation of microscope objectives—Part 1: Flatness of field/Plan》

- 3GB/T 43846.2-2024《Microscopes—Designation of microscope objectives—Part 2: Chromatic correction》

- 4GB/T 43846.3-2024《Microscopes—Designation of microscope objectives—Part 3: Spectral transmittance》

- 5JJF 1914-2011《Calibration Specification for Metallurgical Microscopes》

- 6GB/T 13777-2024《Test method for maturity of cotton fibers—Microscopic method》

- 7JB/T 8230.1-1999《Light microscope Vocabulary》

- 8GB/T 42659-2023《Surface chemical analysis—Scanning probe microscopy—Determination of geometric quantities using SPM: Calibration of measuring systems》

- 9GB/T 42886-2023《Microscopes—Microscopes with digital imaging displays—Information provided to the user regarding imaging performance》

- 10GB/T 9246-2008《Microscopes - Oculars(eyepieces)》

IPRE4XC

IPRE4XC