RUNJIE RJTC-10 coating Adhesion Tester

SE-

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector Kit 50mm$ 1539.00SE

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector Kit 50mm$ 1539.00SE -

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector 20mm$ 1424.00SE

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector 20mm$ 1424.00SE -

KOSON KS-M coating adhesion Detector 20mm$ 917.00SE

KOSON KS-M coating adhesion Detector 20mm$ 917.00SE -

Pushen PS 2658 Pull-out adhesion Tester$ 1121.00SE

Pushen PS 2658 Pull-out adhesion Tester$ 1121.00SE -

Runjie RJ-6000C Bond strength Tester measuring range 0~6KN$ 541.00SE

Runjie RJ-6000C Bond strength Tester measuring range 0~6KN$ 541.00SE

RunJie RJTC-10 Coating Adhesion TesterSPEC

RunJie RJTC-10 Coating Adhesion TesterDetails

RunJie RJTC-10 Coating Adhesion TesterPacking list

- SKU

- NB008582

- Measurement mode

- manual

- Kit diameter

- 20mm/50mm

- Range

- 10KN/0~31.84MPa、10KN/0~5.09MPa

- Resolution

- 0.001KN/0.001MPa

- Accuracy

- ≤±1%F.S

- Force unit

- MPa、KN

- meet the standard

- ISO 4624:2002、GB/T 5210-2006、TB-T2965-2001

- Weight

- 1.8Kg

- piston stroke

- 10mm

RJTC-10 Paint Adhesion Tester (referred to as the Tester) is an instrument developed for testing the positive tensile bond strength between the paint and the attached object. According to the bond strength and failure mode in tension, the test results can be obtained immediately. The Detector is designed with electromechanical integration, and the whole set of instruments is integrated as a whole. Mechanical parts including handles, sensors, leadscrews, and reaction force supports form a "door" structure. At the same time, the measurement display circuit is embedded in the instrument, and the data can be directly observed. The Detector has the characteristics of light weight, labor-saving handle operation, and convenient use.

Standards

ISO 4624:2002 "Paints and varnishes - pull-off adhesion test";

GB/T 5210-2006 "Paints and varnishes - pull-off adhesion test";

TB-T2965-2011 "Technical Conditions for Waterproof Layer of Railway Concrete Bridge Deck";

The main function of the Detector

Function selection: It is suitable for the detection of paint bonding strength.

Measurement options: standard block detection.

Automatic clearing: Automatically eliminate the deviation value after power-on to make the output display a zero value.

Peak hold: In the peak hold state, the maximum tension value is always displayed.

Data storage: The detection value can be stored, and can be recalled and cleared at any time.

Automatic shutdown: with delayed power-off function, prolong battery life.

Linear correction: 5 correction points can be set to correct the data linearity and improve the detection accuracy.

Strength value measurement: MPa value can be displayed directly.

It can detect the bonding strength of paint and various coatings and coatings, and has a wide range of applications.

Detection range 50 standard blocks can detect 0-5.2MPA .

The 20-round standard block can detect the instrument 0-32MPA.

Product Structure

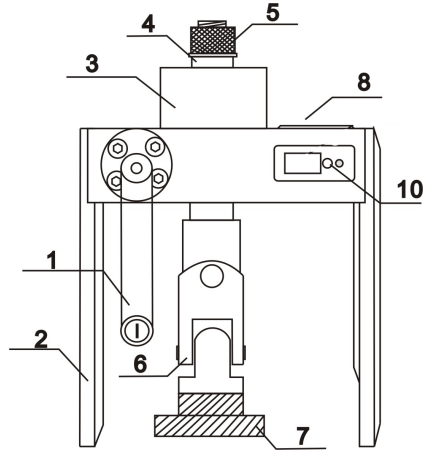

The RJTC-10 adhesion Tester is designed in one piece, the structure of the instrument host and the instrument is shown in the figure below.

1. Handle 2. Support plate 3. Working cylinder 4. Piston 5. Nut 6. Universal tie rod 7. Standard test block 8. Intelligent digital display pressure gauge 10. Charging port

The instrument is also equipped with a set of standard blocks with specifications of 20mm and 50mm.

- 1SH/T 3022-2019《Design standard for anticorrosion coating of equipment and piping in petrochemical industry》

- 2ISO 2819-2017《Metallic coatings on metallic substrates - Electrodeposited and chemically deposited coatings - Review of methods available for testing adhesion (Third Edition)》

- 3ASTM D7234-2012《Standard Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers》

- 4GB/T 39289-2020《Determination of the adhesion strength—Plastic and metal》

- 5ISO 12944.6-2018《Paints And Varnishes - Corrosion Protection Of Steel Structures By Protective Paint Systems - Part 6: Laboratory Performance Test Methods》

- 6GMW 4205《Eletroplating standards for zinc-nickel alloys》

- 7HG/T 4340-2012《Epoxy micaceous iron oxide intermediate coatings》

- 8TB/T 2965-2011《Technical specification for waterproof layer of railway concrete bridge》

- 9ASTM B571-2023《Standard Practice for Qualitative Adhesion Testing of Metallic Coatings》

- 10ISO 9717-2017《Metallic and other inorganic coatings — Phosphate conversion coating of metals》

RJTC-10

RJTC-10