What are the properties of automobile axle leaf spring anti-corrosion primer to be tested?

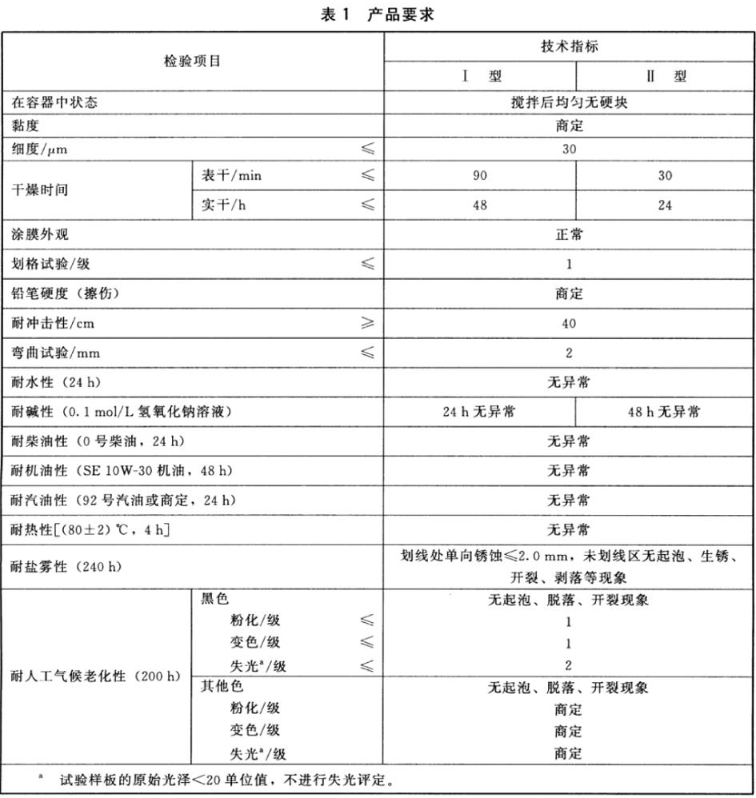

Today we will introduce the regulations of HG/T 5187-2017 on the detection of anti-corrosion primers for automobile axle leaf springs. It is applicable to anti-corrosion primers for automobile axle leaf springs such as passenger cars and buses. Among them, the detection performance of the low-grade automobile axle leaf spring anti-corrosion primer includes the state in the container, viscosity, fineness, drying time, and appearance of the coating film. We can divide the products into Type I and Type II according to the different dispersion media. Type I refers to the water-based anti-corrosion primer for automobile axle leaf springs; type II refers to the solvent-based anti-corrosion primer for automobile axle leaf springs.

Item detection

1. State in the container: First, we open the container and stir with a spatula or stirring rod, and allow precipitation at the bottom of the container. If it is easy to mix evenly after stirring, it is rated as "homogeneous without lumps after stirring".

2. The index of the viscosity test shall be agreed upon by the two sides of the test according to the actual situation, and there are no other requirements.

3. Fineness: It can be seen from the test that if the technical indicators of type I and type II are both ≦30/μm, the standard is met.

4. Drying time: According to the test, the surface drying time of type I is 90 minutes, and the hard drying time is 48 hours; the surface drying time of type II is 30 minutes, and the hard drying time is 24 hours, which is up to the standard.

5. Appearance of the coating film: Visually observe the sample under scattered sunlight. If the coating film is uniform without sagging, blooming, pinholes, cracking and peeling, it is rated as "normal".

6. Cross-cut test: It can be seen from the test that if the cross-cut of type I and type II is less than or equal to grade 1, it is up to the standard.

7. The technical index of pencil hardness shall be negotiated by both parties according to the actual situation, and there is no other requirement.

8. Impact resistance: The test shows that the impact resistance of type I and type II is ≥ 40/cm, which is up to the standard.

9. Bending test: It can be seen from the test that if the bending degree of type I and type II is both ≦2/mm, the standard is met.

10. Water resistance: In addition to edge sealing, the back of the test panel needs to be sealed before testing. Immerse the test panel in water, take it out after the specified test time, and observe it visually under scattered sunlight. If there are no rust, blistering, cracking, peeling, powder falling, obvious discoloration, obvious loss of gloss and other coating film pathological phenomena on two of the three test panels, it is rated as "no abnormality".

11. Alkali resistance: Immerse the test plate in the specified solution, take it out after the specified test time, and observe it visually under scattered sunlight. If there are no rust, blistering, cracking, peeling, powder falling, obvious discoloration, obvious loss of gloss and other coating film pathological phenomena on two of the three test panels, it is rated as "no abnormality". The alkali resistance of type I is 24h without abnormality, and the alkali resistance of type II is 48h without abnormality.

12. Diesel resistance, engine oil resistance, gasoline resistance: immerse the sample in No. 0 ordinary diesel oil, SE 10W-30 engine oil and No. 92 gasoline agreed by both parties, take it out after the specified test time is reached, and observe it under scattered sunlight. Visual observation. If 2 of the 3 test panels have no coating film pathological phenomena such as blistering, wrinkling, peeling, obvious discoloration and obvious loss of gloss, it is rated as "no abnormality".

13. Heat resistance: Put the 3 test panels into the blast oven or high temperature furnace at the specified temperature. After the specified time, take the test panels out of the oven or high temperature furnace and let them cool down to room temperature. If 2 of the 3 test panels have no coating film pathological phenomena such as blistering, cracking, peeling, obvious discoloration and obvious loss of gloss, it is rated as "no abnormality".

14. Salt spray resistance: draw a line parallel to the long side of the test plate for the test, the unidirectional corrosion at the line is ≤ 2.0 mm, and there is no blistering, rust, cracking, peeling, etc. in the unmarked area Phenomenon, after the end of the test, take out the sample for observation. In case of blistering, rusting, cracking and peeling, etc., the damage phenomenon caused by external factors within 5 mm around the edge of the test plate and the plate hole will not be investigated.

15. Resistance to artificial weathering: the test shows that in the black film, there is no blistering, shedding, cracking, pulverization level 1, discoloration level 1, and loss of light level 2 are up to the standard; in other colored films, there is no foaming , shedding, cracking, pulverization, discoloration are up to the standard, and the loss of gloss is agreed by both parties according to the actual situation, and there is no other requirement.

- 1Film hardness testing method: pendulum hardness, pencil hardness, etc

- 2ISO 15184 Pencil method to measure the hardness of paint film

- 3Analysis of hardness measurement by ASTM D3363 pencil method

- 4Pencil Hardness Tester test procedure, application and different Hardness Pencil introduction

- 5Pencil hardness testing of film

- 6Ceramic Coated Pencil Hardness Test

- 7Relevant standards for pencil Hardness Testers

- 8What is a pencil hardness test?

- 9What are the test subjects for perchlorovinyl resin anti-corrosion coatings?