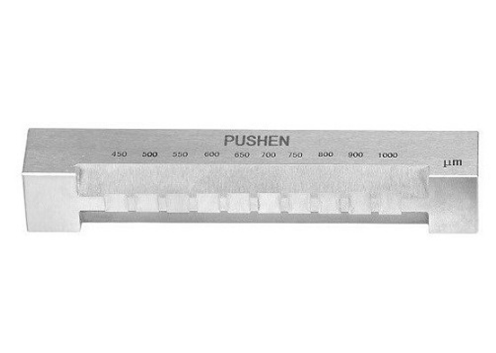

PUSHEN LG 50-275 Sag Tester, groove depth 50-275 μm

SERange 50-275μm; in line with GB, ISO, ASTM standards; 25μm Graduation, the number of grooves 10.

$152.00/piece

PromotionLoading...

Coupon

Model:

Similar products

Pushen LG 50-275 SAG TesterSPEC

Pushen LG 50-275 SAG TesterDetails

Pushen LG 50-275 SAG TesterPacking list

- SKU

- NB018171

- Film thickness range

- 50 ~ 275µm

- Graduation

- 25µm

- Number of grooves

- 10

LG 50-275

SAG Tester

Range 50-275μm; in line with GB, ISO, ASTM standards; 25μm Graduation, the number of grooves 10.

Introduction

Sag is considered a paint defect, especially on vertical surfaces, edges and corners of the workpiece. Common terms such as streaks or tear stains describe this flawed appearance very vividly.

Series Specifications

| order number | groove depth | Division value |

| PS 2522/1 | 50-275μm | 25μm |

| PS 2522/2 | 250-475μm | 25μm |

| PS 2522/3 | 450-1000μm | 50/100μm |

| Other parameters | ||

| Standards | GB/T 9264, ISO 16862, ASTM D 4400, D 3730 | |

| number of grooves | 10 | |

test steps

Ten stripes of various film thicknesses were produced with sag coating.

Immediately after coating, place the test panel in a vertical position with the thinnest film stripe on top and avoid vibration. The convergence of the stripes depends on the tendency to sag.

It is very difficult to reproduce the results of the experiment.

It is very important to ensure the following conditions in the test: stable climate environment, uniformity of coating film, and set evaluation time.

Standards

GB/T 9264

ISO 16862

ASTMD 4400, D 3730

FAQ

QDoes this sag tester meet the JT/T821.2 standard?

A

This sag tester is suitable for JT/T821.2. Please consult customer service for detailed application definition.

QDoes the Purson LG 50-275 sag tester meet the national standard?

A

Hello, it meets the national standard GB9264.

QPurson SAG tester, test 150 microns, which model do you use?

A

Hello, the LG 50-275 model is OK.

Standard

- 1 10302-2023《Sag resistance polyurethane waterproofing coating》

- 2 052-2021《Anti-Sag Meter calibrating specification》

- 3GB/T 27806-2011《Tar epoxy anti-corrosion coatings》

- 4HG/T 4340-2012《Epoxy micaceous iron oxide intermediate coatings》

- 5ASTM D7514-2022《Standard Test Method for Evaluating Ink Stainblocking of Architectural Paint Systems by Visual Assessment》

- 6JT/T 821.2-2011《Anti-corrosive coatings for concrete bridge surface.Part 2:Wet-surface tolerant coatings》

- 7JT/T 821.1-2011《Anti-corrosive coatings for concrete bridge surface.Part 1: Solvent based coatings》

- 8ASTM D4400-2018《Standard Test Method for Sag Resistance of Paints Using a Multinotch Applicator》

- 9ASTM D 4400-1999《Standard Test Method for Sag Resistance of Paints Using a Multinotch Applicator》

- 10JB/T 6886-2010《Ventilator painting technical conditions》

LG 50-275

LG 50-275