How is Film Adhesion Measured?

1 Definition, Purpose and Significance

2 Relevant standards

GB/T1720-79(89) Determination of paint film adhesion

GB/T 9286-1998 Paint and varnish film cross cut. Test

GBIT5210-2006 paints and varnishes-pull-off adhesion test

3 Introduction to key points of inspection methods

3.1 GB/T1720-79(89) Determination of Paint Film Adhesion

3.1.1 Test Principle

Fix the template on a movable platform. While the platform is moving, the stylus moving in a circle penetrates the paint film, and can draw the lines of re-rolling lines. The destructive effect on the paint film, except for the vertical In addition to the pressure, there is also the torsion force generated by the rotating motion of the steel needle.

3.1.2 Materials and equipment

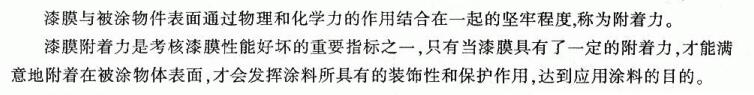

Adhesion Tester: QFZ type paint film adhesion Tester is shown in Figure 4. The screw pitch of the test bench is 1.5mm. 500g, 1000g, the turning radius of the rotary needle is adjustable, and the standard turning radius is 5.25mm.

Tinplate: 120mmx50mmx(0.2-0.3 )mm.

3.1.3 Operation points

Before testing, check whether the stylus needle is sharp, and replace it if it is not sharp. Then check whether the scratches are consistent with the standard radius of gyration. If they do not match, they should be adjusted in time. When measuring, fix the model on the test bench, make the tip of the stylus touch the paint film, move the handle evenly, and the rotation speed should be (80-100) rpm. The standard picture length of scratches is (7.5i0.5) cm. After scratching, take out the model and remove the paint chips on the scratches.

3.14 Result presentation

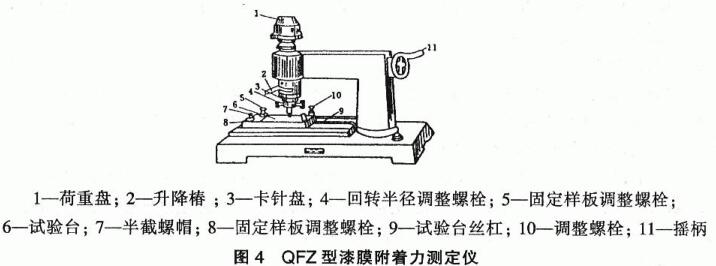

Use a 4x magnifying glass or visually observe the upper side of the scratch, mark 1, 2, 3, 4, 5, 6, and 7 in sequence, and divide them into 7 grades accordingly. As shown in Figure 5. Check the completeness of the paint film at each part in order. If more than 70% of the grids in a certain part are intact, the part is considered intact, otherwise it should be considered damaged. The adhesion of the paint film is represented by the lowest grade of the intact paint film, and the result is based on the same grades of at least two samples, grade 1 is better and grade 7 is the worst.

3.1.5 Precautions

3.1.5.1 The stylus needle needs to be sharp, otherwise it should be replaced in time.

3.1.5.2 The standard radius of gyration should meet the requirements.

3.2 GB/T9286-1998 Cross-cut test of paint and varnish film

3.2.1 Test principle

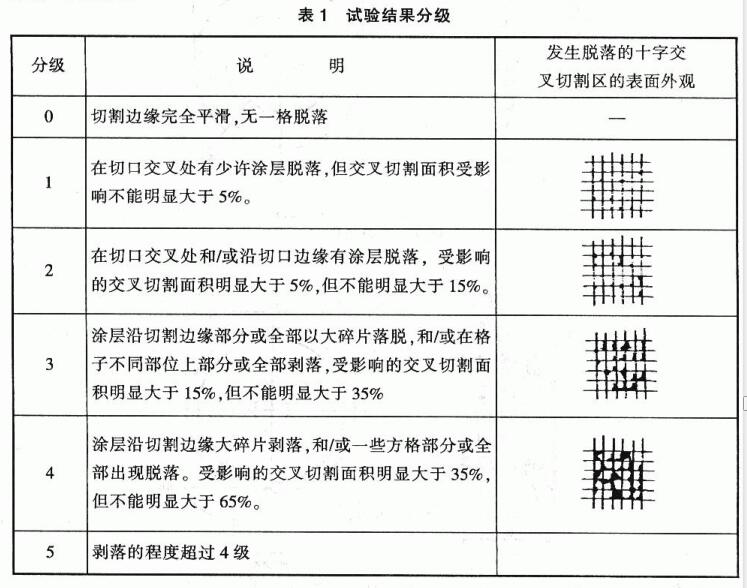

According to the sample substrate and the thickness of the paint film, cut the paint film in a lattice pattern with a grid cutter with different spacing, so that it just penetrates to the substrate, and evaluate the resistance of the paint film to the separation from the substrate. According to the area where the paint film falls off from the substrate in the cross-cut area, it is graded from 0 to 5, with grade 0 being the best and grade 5 the worst.

3.2.2 Materials and equipment

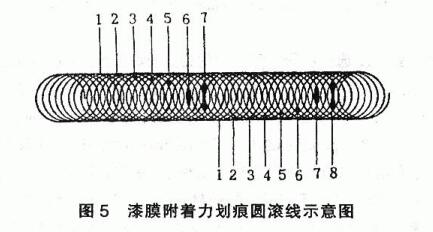

Single knife: As shown in Figure 6, the knife is suitable for any substrate;

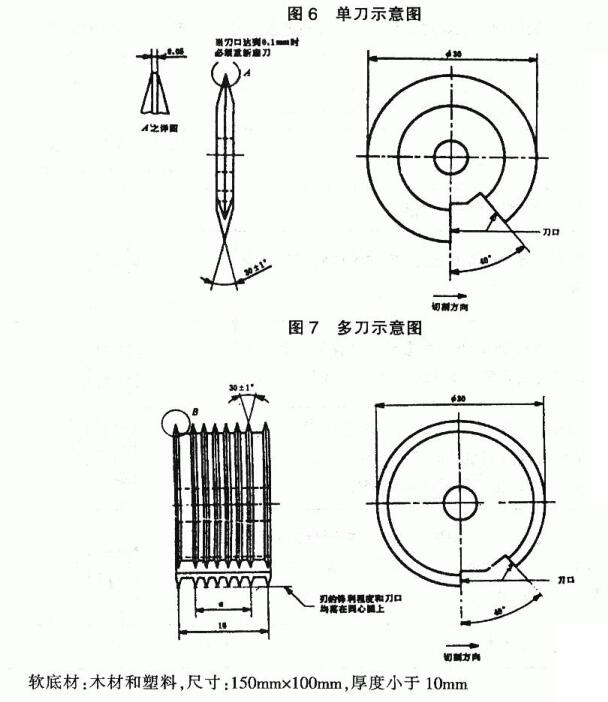

Multi-knife: As shown in Figure 7, the distance between the blades is 1mm and 2mm respectively. This cutter is not suitable for paint film thickness greater than 120µm or hard coatings or coatings applied on soft substrates.

Transparent pressure-sensitive adhesive tape: width 25mm, adhesion force (10±1) N/25mm or agreed upon.

Hard substrate: steel plate, tin plate, etc., size: 150mmx100mm, thickness 0.25mm

3.2.4 Operation points

首先According to底材及漆膜厚度选择不同刀刃间距的刀具:漆膜厚度为(0-60) µm并施工于硬底材上的用刀刃间距1mm的划格刀;漆膜厚度为(0-60)µm并施工于软底材上的用刀刃间距2mm的划格刀;漆膜厚度为(61~120)µm并施工于硬或软底材上的用刀刃间距2mm 的划格刀;漆膜厚度为( 121-250)µm并施工于硬或软底材上的用刀刃间距3mm的划格刀 。选择好刀具后还应检査刀刃是否锋利,否则应予更换 。一块样板上可进行三组切割,每组之间边缘距离应大于5mm ,同时距样板边缘也应大于5mm。 如果是木质底材或类似材料,则应沿与木纹方向呈45°方向进行切割 。 切割时刀垂直于样板表面,均匀施力,匀速切割 。所有切割都应划透至底材,每个方向切割数为6 。 切割完毕,用软毛刷沿网格图形每一条对角线轻轻向后指几次,再向前指几次。 在硬底材的样板上施加胶粘带(软底材不需施加胶粘带) ,除去胶粘带最前面一段,然后剪下长约75mm的胶粘带,将其中心点放在网格上方压平,并使其与漆膜完全接触 。胶粘带长度至少超过网格20前。在贴上胶粘带5min内,拿住胶带悬空的一端,并以尽可能接近60°的角度用(0.5_1.0)s的时间将其撕离。观察漆膜脱落现象。

3.2.5 结果表示

According to表1中对 0-5级的划分规定对漆膜划格区域脱落情况进行判定。以三组切割评定一致的结果报出 。

3.2.6 注意事项

3.2.6.1正确选择刀具。

3.2.6.2 胶粘带的粘贴及剥离角度、时同应按标准规定 。

3.2.6.3 木纹的方向和结构可能影响试验结果,而且明显的木纹会使评定不能进行 。

3.3 GB/T5210-2006色漆和清漆一拉开法附着力试验

3.3.1 测试原理

在规定的速度下,在试样的胶结面上施加垂直、均匀的拉力,以涂层间或涂层与底材拉开时的单位面积、上所需的力表示该涂层的附着力 。

3.3.2 材料和仪器设备

拉力试验机:能施加均匀的且增加不超过1MPfs的应力,使破坏过程在90s内完成,机械式、压缩空气式、液压式或手动式均可 。

试柱:用金属加工而成,直径为20mm或7mm

胶粘剂:胶粘剂的内聚力和粘结性要大于受试涂层的内聚力和粘结性 。

3,3.3 操作要点

3.3.3.1 试验组合的选择

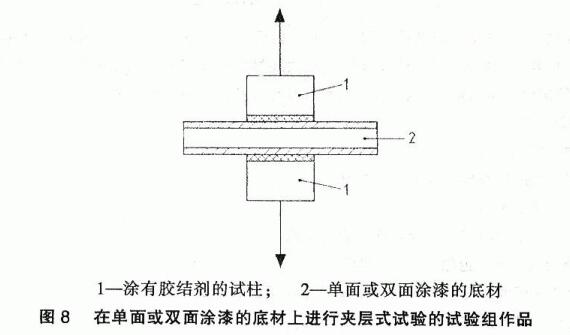

①在坚硬的和易变形的底材上通用的试验方法(使用兩个试柱)

从涂漆底材上裁取试片,直径至少30mm的圆片或边长至少30mm的正方形。将胶粘剂均匀的涂在两个清洁干净且直径相同的试柱的表面上。 将试片放在两个表面涂有胶粘剂的试柱的中间,两个试柱应位于试片的中央且同軸心排列 。見图8。胶粘剂固化后,使用切割装置沿试柱的周线切透至底材 。

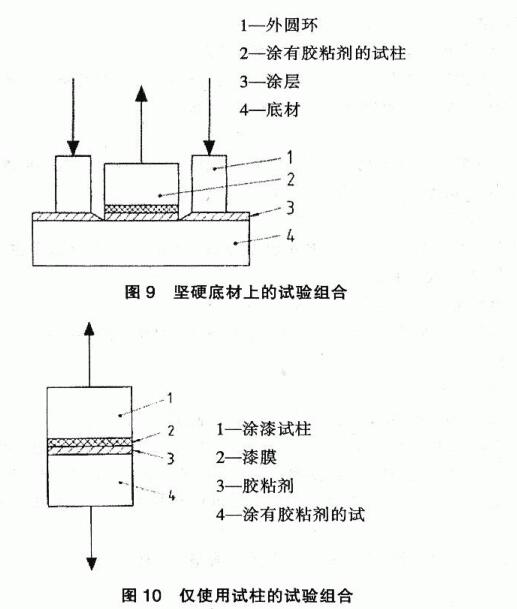

②使用单个试柱从单側进行试验的方法(仅這合坚硬底材)

将胶粘剂均匀的涂在未涂漆的、清洁干净的试柱表面。见图9。胶粘剂園化后,使用切割装置沿试柱的周线切透至底材。

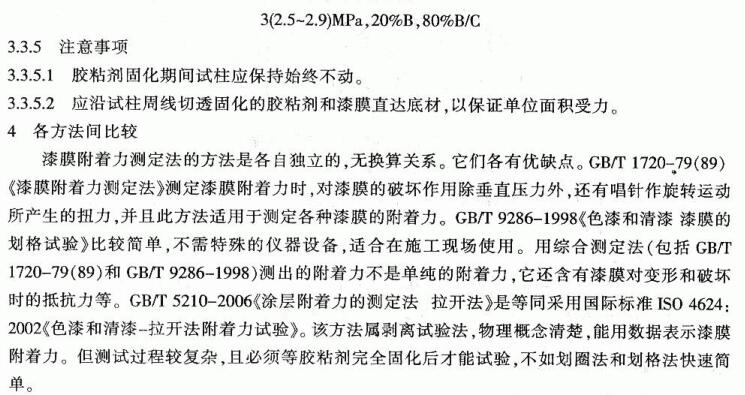

③试柱法,其中一个试柱作为已涂漆底材将胶粘剂均匀的涂在一个未涂漆的、清洁干浄的试柱表面,把试柱的涂有胶粘剂的表面与另一个试柱涂有受试产品的表面相连,見图10。

3.3.3.2 测量

胶粘剂固化后,立即把试验组合置于拉力试验机下。 小心地定中心放置试柱,使拉力均匀地作用于试验面积上而没有任何弯曲动作 。对涂漆底材平面垂直方向施加拉伸应力,该应力以不超过1MPa/s的速度稳步增加,试验组合的破坏应从施加应力起90s内完成。

3.3.3.3 破坏形式

A底材内聚破坏1

A/B 第一道涂层与底材间的附着破坏;

B第一道涂层的内聚破坏;

B/C第一道涂层与第二道涂层间的附着破坏;

N复合涂层的第 n道涂层的内聚破坏;

·m复合涂层的第 n這涂层与第 m道涂层间的附着破坏1

-/Y 最后一道涂层与胶粘剂间的附着破坏;

Cohesive failure of the Y adhesive;

Bond failure between Y/Z adhesive and test column.

3.3.4 Result presentation

For each damage type, estimate the percentage of damaged area to the nearest 10%. Repeat the series of trials on at least 6 trial combinations. The results are expressed in terms of average damage area percentage and damage type. For example, the coating system is destroyed under an average tension of 3 MPa. The inspection shows that the cohesive damage area of the first coating is about 20% on average, and the adhesion damage 80%, so the result of the pull-off method test can be expressed as:

- 1Principle and Application Analysis of Film Adhesion Tester

- 2GB/T 1720 Determination of paint film adhesion: Circle method

- 3Advantages and disadvantages of three methods of film adhesion

- 4Talking about ASTM D4541 film adhesion drawing test

- 5Adhesion Factors of Paints and Coatings & Test Methods

specialchem

- 6What are the tips to prevent sand inclusion and dry spray of paint film?

- 7Analysis of surface defects of blisters/blisters-anti-corrosion coatings

- 8Two defects of paint film adhesion - saponification and undercutting

- 9Operation steps of QFZ circle method paint film adhesion Tester