Flexibility Tester how to choose? Full analysis of key equipment for industrial material testing

1. What is an industrial flexibility Tester?

An industrial flexibility Tester is an instrument that accurately measures a material's ability to resist breakage, cracking, or performance degradation by simulating the deformation scenarios that materials may encounter in practical applications, such as bending, folding, and torsion. Its core value is to convert the "flexibility" of the material into quantifiable data (such as the number of bends, critical angles, resistance values, etc.), which provides a scientific basis for enterprises to judge whether the material meets the production standards and whether it can meet the needs of use.

Examples of typical application scenarios

• Food packaging film: If the flexibility is insufficient, it may break when folded and packaged, causing food to deteriorate;

• Wire and cable insulation: If the bending resistance is poor, it is easy to crack after long-term repeated bending, causing potential safety hazards;

• Building exterior wall coating: If the flexibility is not qualified, it may fall off when the wall is slightly deformed (such as temperature changes), affecting durability.

Therefore, flexibility Testers are a key tool to ensure material quality and reduce the risk of product failure.

2. The main types of industrial flexibility Testers

According to the different test principles, applicable materials and deformation methods, industrial flexibility Testers can be divided into the following categories, each designed for specific materials and application scenarios:

1. Repeated bend Tester

• Test principle: Periodically bend the sample at a full angle of 180° or bend it back and forth at a specific angle (such as 90°, 120°), and record the number of bends when the material breaks, cracks, or performance degradation (such as decreased conductivity).

• Applicable materials: metal wires, metal sheets, wires and cables, plastic strips, springs, and other materials that need to withstand long-term repeated deformation.

• Typical applications: Detect the durability of cables after repeated bending during installation and use; Evaluate the fatigue resistance of metal shrapnel.

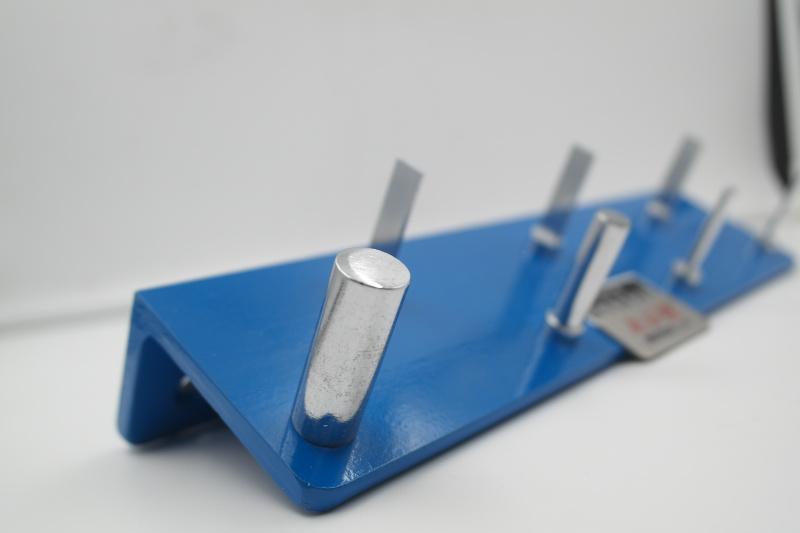

2. Bending (mandrel/cone) Tester

• Test principle: After fixing the material, bend around the cylindrical mandrel or tapered test bench of different diameters, and adjust the bending radius or angle to observe whether the surface of the material cracks and whether the coating falls off, so as to determine the minimum bendable critical value of the material.

• Applicable materials: Thin or coated materials such as plastic film, aluminum foil, coated steel plate, leather, and composite materials.

• Typical applications: mobile phone protector corner bending test (simulating daily bumps); Crack resistance detection of building exterior wall coatings during wall microdeformation.

3. Folding resistance Tester

• Test principle: The sample is folded 90° alternately left and right (similar to turning the pages of a book) until the material breaks, and the number of folds is used as an index to measure its folding resistance.

• Applicable materials: paper, cardboard, thin cardboard, flexible packaging materials, etc.

• Typical applications: reading resistance testing of book paper; Evaluation of the anti-damage ability of express cartons during folding, packaging and transportation.

4. Torsional flexibility Tester

• Test principle: Evaluate the flexibility of the material under torsional stress by applying controlled torque to the tubular or linear material, measuring its degree of deformation, recovery ability and torque value at breakage during torsion.

• Applicable materials: rubber pipes, plastic pipes, wires and cables, hoses, etc.

• Typical applications: crack resistance testing of water pipes due to bending and torsion during installation; Torsional fatigue detection of industrial hoses in mechanical motion.

5. Dynamic flexibility Tester

• Test principle: Unlike static testing, this type of equipment applies varying forces, velocities, or frequencies during the test, simulating the flexibility of materials under dynamic conditions (such as vibration and shock) and recording the performance decay curve of materials under complex deformation.

• Applicable materials: elastomers, rubber, TPE (thermoplastic elastomers), automotive seals, and other materials that need to withstand dynamic stress.

• Typical applications: Testing the flexibility retention ability of automotive tire rubber during long-term rolling; Evaluation of fatigue resistance of elastic parts in sports equipment.

3. Key points of selection of industrial flexibility Testers

When selecting a model, it is necessary to combine material characteristics, test standards and actual scenarios to avoid "over-function" or "under-performance", which can be considered from the following dimensions:

1. Clarify the material type and testing requirements

The structure and accuracy requirements of different materials for test equipment vary significantly:

• Hard and brittle materials such as metal/wire: choose a repeated bending Tester with strong wear resistance and accurate force measurement;

• Thin materials such as films/coatings: Prefer bend (mandrel/tapered) Testers that support fine bend radius and angle adjustments;

• Brittle materials such as paper/cardboard: A folding resistance Tester is a suitable choice, and it is necessary to pay attention to the stability of the folding angle and the accuracy of counting;

• Tubular materials such as tubes/hoses: Torsional flexibility Testers are more suitable for needs, and it is necessary to confirm the torque range of the equipment and the method of holding the sample;

• Dynamic stressed materials such as elastomers/rubbers: Dynamic flexibility Testers are essential and need to support variable force/velocity adjustment.

2. Benchmark industry standards

Each industry has clear specifications for flexibility testing, and it is necessary to ensure that the equipment meets relevant standards when selecting to avoid unrecognized test data. For example:

• Packaging industry: Comply with GB/T 1040.3 (tensile performance test for plastics) and ASTM D522 (coating bending test);

• Paper industry: ISO 5626 (paper bending resistance test), TAPPI T511 (MIT bending resistance standard);

• Wire and cable industry: refer to IEC 60811 (cable insulation material test), ASTM D1043 (rubber hose test);

• Architectural coatings industry: Meet the relevant requirements for flexibility in GB/T 9286 (Grid test for colored paints and varnishes).

3. Focus on core performance parameters

• Bending angle range: selected according to the maximum bending angle in actual use of the material (such as packaging materials often need to be folded 180°, equipment needs to support full-angle bending);

• Test accuracy: scientific research or high-end manufacturing industries need to choose high-precision equipment (such as angle accuracy ±0.1°, force accuracy ±0.5%), and routine quality testing can be appropriately relaxed;

• Degree of automation: production line sampling is suitable for semi-automatic equipment (fast results), laboratory testing requires fully automatic equipment (support data recording, curve analysis and export);

• Sample compatibility: The equipment should be able to adapt to samples of different sizes (such as film width, tube diameter) and shape to avoid affecting the test results due to instability in fixation.

4. Match usage scenarios

• Laboratory precision testing: Choose a comprehensive benchtop device (such as a dynamic flexibility Tester) that supports multi-parameter adjustment and in-depth data analysis.

• Rapid sampling of production lines: Prioritize small equipment that is portable and easy to operate (such as handheld folding resistance Tester) to improve testing efficiency;

• Harsh environment testing: For example, workshops and outdoor venues, dust-proof and vibration-resistant equipment should be selected to ensure test stability.

epilogue

In industrial production, flexibility Testers are not only the "gatekeepers" of quality control, but also the "compass" of product development. The key to proper selection is to accurately match material properties, industry standards, and usage scenarios—without overly pursuing high-end features that cause cost waste or neglecting core performance that leads to data distortion. Through the scientific selection and use of flexibility Testers, enterprises can effectively improve material reliability, reduce the risk of product failure, and establish quality advantages in the fierce market competition.

-

-

-

JFL QTB putty flexibility Tester$ 222.00

-

PUSHEN RTG putty flexibility Tester$ 300.00

-

-

-

-