Combustion Test Chamber? Application, troubleshooting and maintenance key points

1. Definition and working principle of equipment

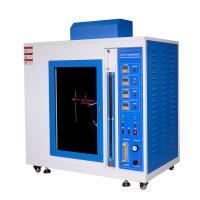

Combustion Test Chambers are specialized equipment used to accurately evaluate the combustion characteristics of materials, measuring parameters such as flammability, fire resistance, smoke volume and combustion residue by simulating a controlled flame environment. Its core principle is to simulate various fire scenarios from smoldering to violent combustion by precisely controlling the three elements of combustible (material itself), oxygen (combustion environment) and ignition source (gas flame).

The modern equipment is equipped with gas flow controller (supporting natural gas/propane), multi-point temperature monitoring, smoke density measurement and automatic data system, which strictly complies with UL, ASTM, ISO, GB and other international and domestic standards, providing a scientific basis for the classification of material flame retardant grades.

2. Core composition and technical characteristics

The equipment is mainly composed of combustion chamber, gas control system, temperature monitoring system, timing device, data recording module and safety protection device. Flame intensity is controlled by precisely adjusting gas pressure and nozzle structure, and with high-precision temperature sensors and smoke Detectors, key data during the combustion process is collected in real time. Its technical advantages lie in the ability to reproduce real fire conditions, the high degree of repeatability of test results, and are widely used in material research and development, safety certification, and quality control.

3. Main application fields

1. Building materials: Evaluate the flame retardant properties of wall insulation materials, flooring, decorative panels, etc., to ensure that high-rise buildings and public facilities meet fire protection standards.

2. Electronic and Electrical Appliances: Testing the flame retardant properties of components such as plastic shells and cable insulation layers to prevent the spread of electrical fires.

3. Transportation: Detect the combustion characteristics of automotive interiors and rail transit materials in enclosed spaces, focusing on smoke toxicity and droplet risks.

4. Aerospace: Verify the special combustion performance of materials in aircraft cabins in high-altitude and low-oxygen environments, with extremely strict safety standards.

5. Textile Furniture: Evaluate the flame retardant treatment of textiles such as curtains and seat fabrics used in public spaces.

6. Scientific research and education: Support the research and development of flame retardant materials and the research of fire mechanisms, and cultivate professionals.

4. Common fault handling

1. Flame control problems: check gas pressure stability, clean ignition electrode carbon deposits, unclog nozzles, calibrate gas control systems.

2. Abnormal Temperatures: Calibrate or replace temperature sensors, check the integrity of heating elements, optimize PID control parameters, and reduce environmental interference.

3. Smoke measurement error: clean the photoelectric sensor window, check the sampling pump and pipeline patency, and perform regular system calibration.

4. Mechanical structure failure: replace the aging seal strip, lubricate the transmission parts, clean the smoke exhaust system, and repair the box deformation.

5. Data System Failure: Back up test data, check storage device status, ensure power stability, and eliminate electromagnetic interference.

5. Key points of maintenance

1. Daily inspection: Confirm that the gas connection is free of leaks, the electrical wiring is intact, test the emergency stop function, and clean up the combustion chamber residue.

2. Regular Maintenance:

• Weekly: Clean the combustion chamber, check the ignition system, verify the temperature sensor

• Monthly: calibrate the measurement system and test the safety interlock function

• Quarterly: Professional calibration of critical systems

• Annual: Fully review and update the software

3. Special Note: Promptly clean up residues after testing, operated only by professionals, and must be powered off and safety locking procedures must be performed before maintenance.

6. Summary

Combustion Test Chambers, as the core equipment for evaluating the fire performance of materials, play a key role in ensuring public safety. As materials science and safety standards continue to evolve, so do their testing techniques. Only by correctly understanding the principle, application scope and maintenance requirements of the equipment, and establishing a scientific maintenance system can we ensure the accuracy and reliability of test data and provide strong support for fire safety in various industries. For high-frequency use laboratories, a perfect equipment management system and professional training are the basis for giving full play to the effectiveness of equipment.