How to test the porosity of anticorrosive pipe coatings?

According to the oil and gas industry standard SY/T0315-97, the determination of the porosity of the anti-corrosion pipeline coating is carried out as follows.

(1) Equipment required for the test

① Stereo microscope.

② Bench vise or special bending machine.

③Dry ice or freezer.

④Universal pocket knife.

(2) Test piece laboratory coating test piece

The size of the test piece is about 200mmX25mm><6mml, and the size of the test piece is about 200mmX25mmX pipe wall thickness, of which 200mm is the axial dimension of the pipe section. Each group of test pieces is 3 pieces.

(3) Test procedure

① Cool the test piece to below -30°C, and bend it to 180° on a vise or a special bending machine.

② Pry off a piece of coating on the curved test piece, and observe the porosity of the coating with a magnification of 4o.

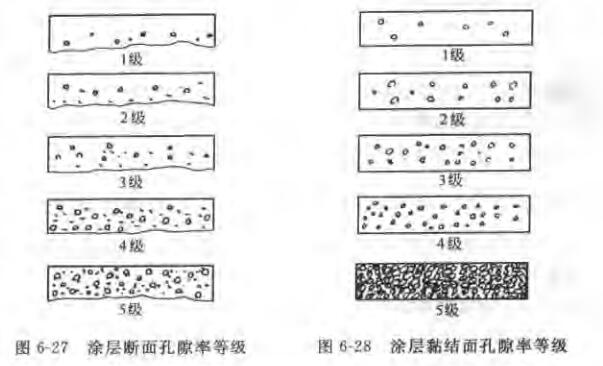

③Assess the porosity grade of the test piece according to the grade chart shown in Figure 6-27 and Figure 6-28.

(4) Result representation

The test set with the lowest level among the three test pieces represents the porosity level of the new surface and the porosity level of the delaminated and cut surface of the group of test pieces respectively.

- 1Analysis of Surface Defects of Explosion Holes and Fisheye-Anticorrosive Coatings

- 2What is an anti-corrosion coating?

- 3How to test paint quality and why is paint testing required?

- 4Lithium-ion battery separator performance testing scheme [with instrument list]

- 5Failure of anti-corrosion coatings

高瑾 米琪 - 《《防腐蚀涂料与涂装》》

- 6Coating flkn measurement coating porosity

- 7Double top coating: how it works, how to apply it

Shivananda Prabhu

- 8Common methods and improvement of coating porosity inspection

- 9Pinholing and porosity detection methods