What performance tests must be performed on the protective film?

Polyethylene (PE) protective film is a pressure-sensitive adhesive made of special polyethylene (PE) plastic film as the base material, polyester resin as the main material, and processed with several special additives. Soft texture, good adhesion, easy to paste, easy to peel off, no residue peeling.

The parameter viscosity of the protective film refers to the amount and quality of glue applied. The quality of the protective film depends on the quality of the glue and the quality of the original film. So how do we know the quality of the protective film? Today we will demonstrate a method for testing the quality of the protective film.

1. Mechanical performance test:

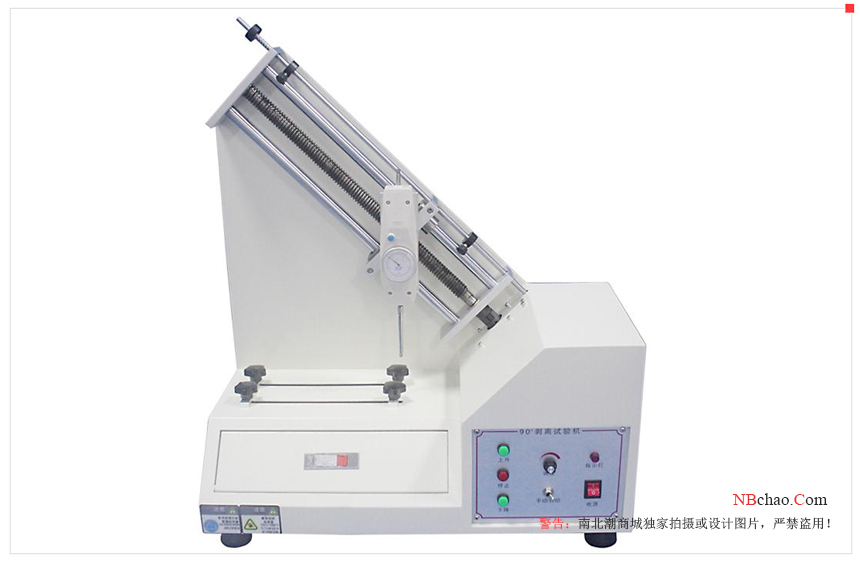

1. Peel strength: used to peel off the protective film of the silicone coating release test of the PE plastic face mask.

2. Adhesive strength: It is used to detect the initial adhesive performance and long-lasting adhesive performance of the protective film to prevent it from falling off after a period of use.

3. Elongation: used to detect the elongation and toughness of the protective film. Good toughness, good elasticity and elongation, strong impact resistance; poor toughness, high brittleness, easy to tear, and poor impact resistance.

2. Environmental tolerance test:

1. Aging resistance test: 300W ultraviolet rays are irradiated for 240 hours under 50 conditions, no cracking, deformation, and no residual glue on the surface.

2. Moisture-proof test: 1 hour of light + 1 hour of rain and 240 hours of rain will not fall off, and there is no residual glue on the surface after peeling.

- 1The Principle and Mechanism of Viscosity Holder and Its Application

- 2Lasting Adhesive Tester for Adhesion Testing of Protective Films

- 3Application sticker for Lasting Adhesive Tester

- 4How is Lasting Adhesive Tester applied to medical patches?

- 5Application of Lasting Adhesive Tester in Pressure Sensitive Tape

- 6What is a peel strength Tester and what is it used for?

- 7What is a stripping test?

- 8Effect of Printing ink on Adhesion Fastness of Composite Films

- 9Test method for tensile strength of fabrics