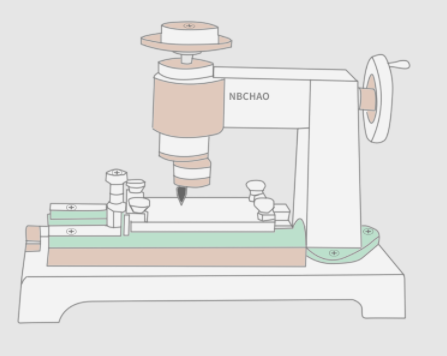

Operation steps of QFZ circle method paint film adhesion Tester

1. Purpose:

This instrument is used to measure the adhesion of various coating films to the surface of the object to be coated.

2. Structural principle:

1. The main transmission part is composed of a hand wheel, a sprocket, and a helical helical gear. When the hand wheel is turned, the worktable moves left and right, and the needle is drawing a circle at the same time.

2. The drawing head is composed of the following two components.

A. The double-headed square screw is used to adjust the machine head up and down.

B. The drawing diameter is adjusted by connecting the lower dovetail plate with a sliding dovetail and a screw that can drive the hand tracing needle.

3. The workbench is equipped with a movable half nut connected to the lead screw at one end to drive the workbench to move back and forth. There are four nuts and two pressure plates on the workbench for pressing and releasing the test piece.

4. The base part is used to support the workbench and tracing head, etc.

3. Specifications:

1. The diameter of the drawing figure: 0~10.5mm

2. Effective area of workbench: 50mm*100mm

3. There are four weights, one for 500 grams, two for 200 grams, and one for 100 grams

4. The needle head adopts 808 brand stylus, which can be easily replaced and used less than 5 times.

5. The effective stroke of the workbench is not less than 80 mm.

4. How to use:

1. Prepare samples according to the requirements.

2. Check the steel needle. It is recommended to replace it with a new steel needle at the beginning of use. The distance between the needle tip and the work surface is about 3 mm.

3. Adjust the eccentric position of the needle tip according to the required drawing diameter, and then tighten it with screws.

4. Put the prepared sample with the coating film facing up and install it on the workbench and press it tightly with a pressure plate.

5. Add weights on the weight plate according to the regulations.

6. Lift the movable half nut to move the workbench to the outer end, and then put down the movable half nut.

7. Turn the pressure lever to make the needle tip contact with the membrane surface.

8. Shake the hand wheel, and the steel needle will draw a spiral pattern on the sample plate. According to the pattern, the adhesion of the coating film can be judged as excellent, good, medium, poor, and poor.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof