What is the cause of poor coating adhesion?

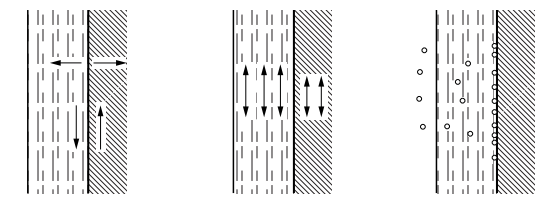

The bond between the coating and the substrate is subject to stress and may eventually fail due to a number of external factors acting alone or in combination. First, there may be regular mechanical stresses that affect not only the volume of the material but also the bond strength at the interface. It is useful here to distinguish between two common types of stress: effective tensile stress perpendicular to the interface and shear stress occurring along the interface.

In addition, since the coating may undergo temperature changes, sometimes rapidly, any difference in the coefficient of expansion may cause such high strength under interfacial stress conditions that the paint film may detach from the substrate.

This event can be particularly detrimental because the effects of temperature are often not as pronounced as mechanical and chemical factors. Of course, there could be an effect of a chemical that penetrates the coating and becomes absorbed at the interface causing loss of adhesion here.

Mechanical 1 Thermal 2 Chemical 3

1--combination of tensile and shear stress; 2--difference in shrinkage and expansion; 3--media penetration and adsorption (water, gas, ions) at the interface

Figure 6.2 External conditions of the interface between the polymer layer and the substrate

It is always useful to account for these effects when it is necessary to measure adhesion, as the method of testing a coating should reproduce end-use conditions.

Adhesion measurement

There are various possibilities to characterize the results obtained in adhesion tests. If it is desired to evaluate the bond strength at the interface, the quantity to be measured is obviously the maximum mechanical stress achievable at the interface. This is the adhesion strength in the strict sense expressed as force per unit area and specified as tensile or shear stress. Therefore, in several test methods, the results are of this form.

The energy required to break chemical bonds at the interface can also be an information quantity. It is expressed as the work of adhesion and is formally equal to the product of the previously defined adhesion strength and the distance between the separating surface and the substrate after the coating is peeled off. Therefore, this quantity has the magnitude of force per unit length, which is what is obtained by some other test methods, such as the peel test.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof

-

-

-

-

-

-

Pushen 20mm spindle$ 76.00