The composition of the circle adhesion instrument? How to judge the test results?

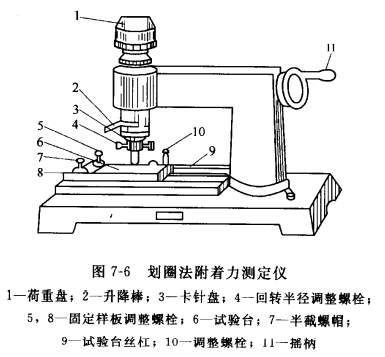

GB 1720-89 "Test Method for Coating Adhesion", that is, the circle method, is mainly used for the determination of coating adhesion on laboratory test panels. It adopts high-hardness and wear-resistant needle tip, which can be used for a long time. It can draw a certain length and sequentially overlapping circular linear graphics on the surface of the coating film (requires scratching through the coating film).

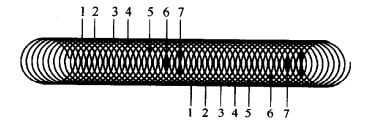

Take the top of the circle drawn on the template as the inspection target, and mark 1, 2, 3, 45, 6, and 7 parts in turn. It is divided into seven levels. Check the integrity of the paint film at each part in sequence. If more than 70% of the lattice of a part is intact, the part is judged to be intact, otherwise it is considered damaged. If the first part of the paint film is intact, it is determined that the best adhesion is grade I; the first part of the paint film is damaged, the second part of the paint film is intact, and the adhesion is poor, which belongs to grade II. By analogy, grade 7 has the worst adhesion. A standard scratched round rolling line is shown in the figure below.

The results are based on the peers of at least two samples.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof

-

-

-

-

-

-

Pushen 20mm spindle$ 76.00