Analysis of surface defects of blisters/blisters-anti-corrosion coatings

Blistering is a common coating defect. The interior is sometimes dry and sometimes liquid. The shape is a hemispherical blister, which varies in size. Dimensions are usually related to the strength of the adhesion to the substrate, or the bond strength between coatings, and the pressure in air or blisters. Blistering sometimes occurs between the coating system and the substrate, and sometimes between coats. Also, sometimes a single coat can also blister. This is mainly due to either air or solvent trapped in the film , but not as much as the other two.

Soluble pigments in primers often cause blistering. Soluble pigments absorb moisture and water vapor and pass through the coating to produce a relatively concentrated solution. At this time, osmotic foaming occurs. Blistering is inevitable when the paint contains soluble substances. Such blisters are generally caused by osmosis. For the same reason, osmotic blistering can also occur if soluble salts are present on the substrate or between coats.

Blistering can also be caused by impurities on the surface, such as grease, paraffin, dust, etc., which are factors that reduce the adhesion of the coating. Moisture will penetrate to the places where the coating adhesion is low, and then it will be easy to blister.

When cathodic protection and coating systems are used together, if there is too much cathodic protection, sufficient hydrogen gas is generated on the metal substrate under the coating, and the resulting pressure can cause blistering.

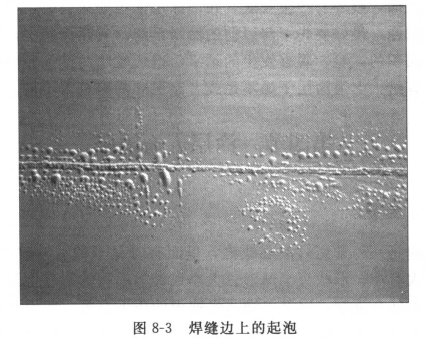

Corroded old steel surfaces are prone to pitting and blistering due to the presence of salt and oxides in the corrosion pores. Corrosive gases such as H2S, HCI, and C2 will be absorbed through the coating, react with the surface of the substrate, and the resulting pressure will cause the coating to arch. It can also be caused by welding fumes left over from electric welding.

The solvent in the paint has poor volatility, and if it remains in the paint, it will also cause foaming. Solvent sensitivity to water can increase the uptake of water molecules in the film and the transfer of water in the paint. If the paint itself has poor adhesion, the paint will blister as its water resistance decreases. The surface temperature of the coating will also cause the residual solvent to generate enough vapor pressure to cause the coating to bubble.

- 1Film adhesion detection method and its applicability analysis

- 2Purpose, method, principle and operation points of coating adhesion test

- 3Working principle and application of UV coating Cupping testing device

- 4Principle and Application Analysis of Film Adhesion Tester

- 5Optical inspection device Anti-reflection film adhesion Measuring method

- 6Automatic scratch test to evaluate film strength, hardness, adhesion

- 7Comparison of film adhesion determination methods

- 8Determination of film adhesion

- 9Paint film adhesion and test method thereof