Plastic parts surface treatment process -- Adhesion

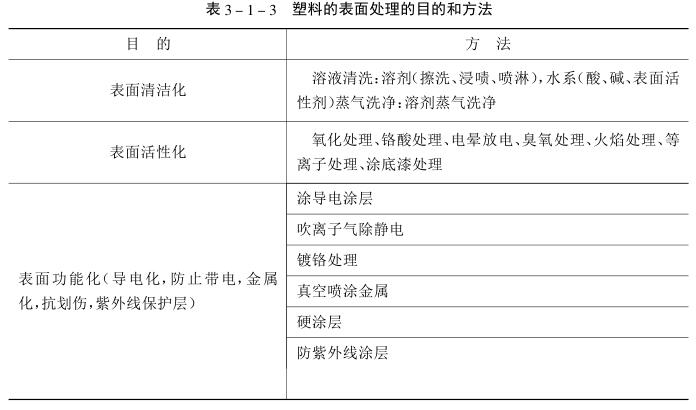

The purpose and method of surface treatment of plastic substrates are shown in Table 3-1-3. The purpose of surface treatment can be divided into three aspects: surface cleaning, surface activation, and surface functionalization.

1. Cleaning is for the purpose of removing dust, particles, oil, moisture and other foreign matter and fragile layers on the surface.

2. Activation is to make the coating film adhere, usually by oxidation treatment, and in a broad sense it also includes bottom treatment (primer coating).

3. The so-called surface functionalization refers to the prevention of electrification, metal surface (electroplating layer), etc. (some of this item does not belong to the scope of coating).

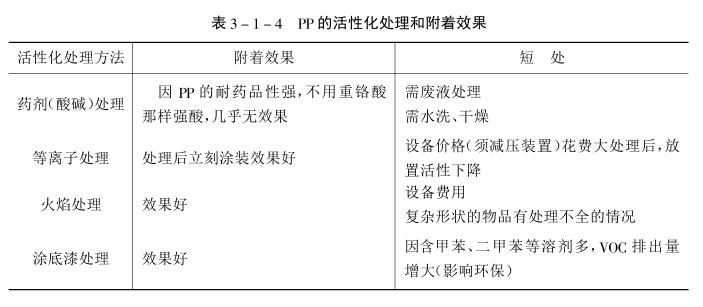

The method of surface activation treatment of polypropylene plastic is shown in Table 3-1-4. Plasma treatment, flame treatment and priming are commonly used in industry.

In Japan, primer treatment has the advantages of versatility, adhesion stability, functionalization (conductivity, coloration), etc., and has become the mainstream method of PP surface treatment. (Related instrument: adhesion Tester)

- 1Polyurethane-graphene composite prepative film

- 2The relationship between film with light, semi-light and no light and actual use

- 3Glossmeter for paints film gloss detection

- 4Adhesion Factors of Paints and Coatings & Test Methods

specialchem

- 5How to evaluate the surface treatment?

- 6What are the common methods of chemical surface treatment?

- 7What are the types of surface treatment technologies?

- 8What are the influencing factors of surface treatment strength?

- 9What are the functions of plastic surface treatment?

-

-

FARUI FR-10S coating Adhesion Tester$ 1089.00

-

-

-

-