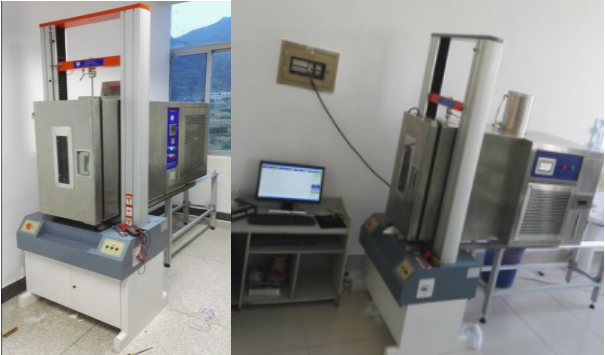

FARI FR-103G high-low temperature tensile machine 0.5 grade

SEFaRui FR-103G High-low temperature tensile machineSPEC

FaRui FR-103G High-low temperature tensile machineDetails

FaRui FR-103G High-low temperature tensile machinePacking list

- SKU

- NB014109

- Maximum test force

- 5KN, 10KN, optional within

- Accuracy class

- Level 0.5

- Force range

- 0.4~100%F.S

- Force value Accuracy

- ±1%, ±0.5%

- Force value resolution

- The maximum load is 1/300000, the inside and outside are not divided into gears, and the whole resolution remains unchanged

- Load Sensors

- Basic configuration: one pull and pressure Sensors (maximum load), extended configuration: multiple Sensors can be added

- Effective test width

- 420mm (can be widened according to customer requirements)

- Efficient stretch space

- 400, 500mm (can be increased according to customer requirements) room temperature 900MM

- Test speed range

- 0.001~500mm/min

- 位移Resolution

- 0.2%~100%FS

- Deformation measurement system

- Exhibition configuration: large deformation: minimum gauge distance 10mm, deformation range: 800mm Large deformation error of indication: within ± 0.5% of indication; large deformation measurement resolution: 0.008mm

- Deformation indication Accuracy

- Within ± 0.5% of the indication

- Test bench Safety Devices

- Electronic limit protection

- Deformation measurement system

- Extended configuration: large deformation: minimum gauge distance 10mm, deformation range: 800mm Extended configuration: small deformation: gauge distance 25mm, 50mm, 100mm Deformation range: 5mm, 10mm, 25mm

- Deformation measurement Accuracy

- Within ± 0.5% of the indication (large deformation or small deformation can be selected according to customer requirements)

- Force control speed adjustment range

- 0.005~5%FS/s

- Accuracy class

- Level 0.5

Introduction

FR-103G computer servo type high-low temperature material testing machine (high-low temperature double column) is a new type of material testing machine combining electronic technology and mechanical transmission. It has wide and accurate loading speed and force measurement range, and can measure load and displacement And control has high precision and sensitivity, and can also carry out automatic control tests of constant velocity loading and constant velocity displacement. It is easy and convenient to operate, and is especially suitable as a testing instrument for controlling product quality on the production line. This series of models is mainly suitable for the test of non-metallic and metallic materials with a test load less than 20KN.

The main function

It is mainly suitable for testing metal and non-metal materials, such as rubber, plastic, wire and cable, fiber optic cable, seat belt, safety belt, leather belt composite material, plastic profile, waterproof coil, steel pipe, copper material, profile, spring steel, Bearing steel, stainless steel (and other high-hardness steel), castings, steel plates, steel strips, and non-ferrous metal wires have tension, compression, bending, shearing, peeling, tearing, and two-point extensions in high-temperature environments (need to be ordered separately) Extensometer) and other tests.

main feature

Imported photoelectric encoder is used for displacement measurement, the controller adopts embedded single-chip microcomputer structure, built-in powerful measurement and control software, which integrates measurement, control, calculation and storage functions. It has the function of automatically calculating stress, elongation (extensometer needs to be added), tensile strength and elastic modulus, and automatically counts the results; automatically records the force value or elongation of the maximum point, breaking point, and designated point; uses a computer for testing The process and test curves are dynamically displayed, and data processing is performed. After the test is over, the curve can be zoomed in through the graphics processing module for data re-analysis and editing, and reports can be printed. The product performance has reached the international professional level.

Standards

"GB/T16491-1996 Electronic Multifunctional Testing Machine"

Application

Widely used in measurement and quality inspection; clothing and footwear; rubber and plastics; metallurgy and steel; machinery manufacturing; electronic appliances; automobile production; textile and chemical fiber; wire and cable; packaging materials and food; instruments and meters; medical equipment; civil nuclear energy; Universities; scientific research laboratories; commodity inspection and arbitration, technical supervision departments; building materials and ceramics; petrochemicals; other industries.

- 1GB/T 45939-2025《Co-extrusion encapsulant film for photovoltaic module》

- 2YB/T 4634-2017《Continuously hot-dip aluminum-zinc-magnesium alloy coated steel sheet and strip》

- 3JC/T 207-2011《Asphalt caulks for building waterproofing》

- 4JB/T 9375-2014《Mechanical Tensile Testing Machines.Specification》

- 5JB/T 9373-2014《Tensile-creep testing machines.Specification》

- 6 10302-2023《Sag resistance polyurethane waterproofing coating》

- 7 10310-2023《Waterborne polyurethane waterproof coating》

- 8GB/T 17642-2008《Geosynthetics - Geocomposites made of geononwoven and geomembrance》

- 9GB/T 16865-2023《Samples and methods for tensile testing of wrought aluminium, mg and their alloys》

- 10GB/T 10802-2023《General flexible polyurethane cellular plastics》

FR-103G

FR-103G