KAIRDA NDT160 Roughness Gauge split surface roughness Tester

SE-

IPRE RA150 asperity Profile Gauge resolution 0.02μm$ 11826.00SE

IPRE RA150 asperity Profile Gauge resolution 0.02μm$ 11826.00SE -

LEEB462 surface roughness multiparameter measurement supports bluetooth printing and mobile app$ 1324.00SE

LEEB462 surface roughness multiparameter measurement supports bluetooth printing and mobile app$ 1324.00SE -

LEEB432 Surface Roughness Tester multiparameter measurement Measurement range 160μm$ 980.00SE

LEEB432 Surface Roughness Tester multiparameter measurement Measurement range 160μm$ 980.00SE -

LEEB400 Portable Roughness Gauge Measurement parameters Ra, Rz, Rq, Rt$ 619.00SE

LEEB400 Portable Roughness Gauge Measurement parameters Ra, Rz, Rq, Rt$ 619.00SE -

PRSR210 Digital Roughness Gauge supports 13 measurement parameters

PRSR210 Digital Roughness Gauge supports 13 measurement parameters

KairDa NDT160 Roughness GaugeSPEC

KairDa NDT160 Roughness GaugeDetails

KairDa NDT160 Roughness GaugePacking list

- SKU

- NB014491

- Display

- digital display

- Measurement parameters

- Ra,Rz,Rq,Rt,Rp,Rv,R3z,R3y,Rz(JIS),Rs,Rsk,Rsm,Rku,Rmr; Ry(JIS);Rmax,RPc,Rk,Rpk,Rvk,Mr1,Mr2

- Measuring range

- Z-axis (vertical): ± 80μm/± 160µm (enhanced); X-axis (horizontal): 20mm

- resolution

- Z( ): 0.01μ m / ± 20μ m 、 0.02μ m / ± 40μ m 、 0.04μ m / ± 80μ m 、 0.08μ m / ± 160μ m

- Error of indication

- ≤±10%

- Indication of variability

- ≤6%

- Sampling length

- 0.25,0.8,2.5mm

- Evaluation length

- Ln = lr × n n = 1 ~ 5

- Sensors - Radius

- 5μm

- Sensors stylus

- Natural diamond, 90 cone angle, 5 μm tip radius

- Sensors - Force Measurement

- 4mN

- Sensors - Angle

- 90 cone angle

- Sensors - measurement principle

- Displacement differential inductor

- Drive speed - when measuring

- lr=0.25, Vt=0.135mm/s;lr=0.8, Vt=0. 5mm/s;lr=2.5, Vt=1mm/s

- Drive speed - when returning

- Vt=1mm/s

- filter

- RCPC-RCGAUSSD-P

- Measurement profile

- Linear dispersion, Roughness profile, Direct profile

- Power

- Built-in lithium-ion rechargeable battery, charged with DC5V, 800mA charger

- Dimensions

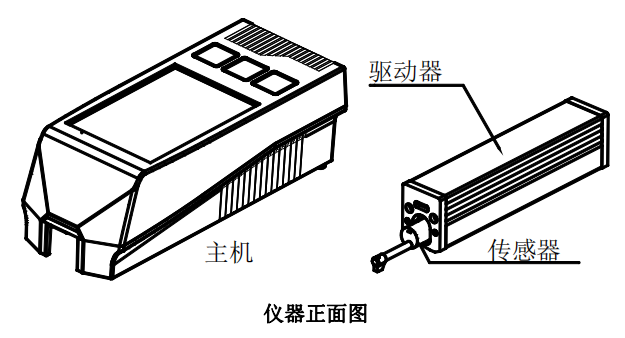

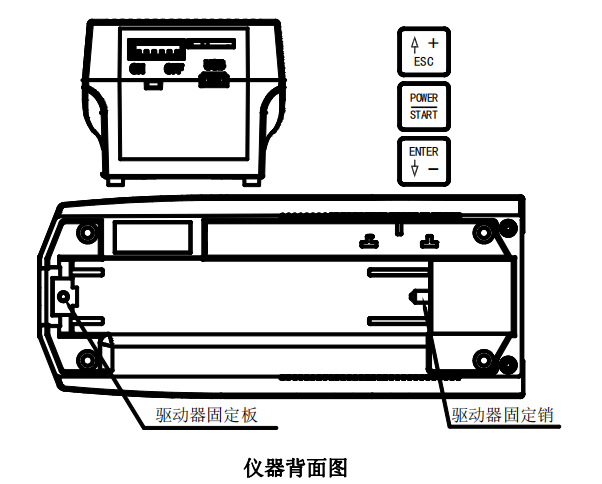

- Host: 64 * 53 * 160mm Driver: 23 * 27 * 115mm

- Product Weight

- About 380g

- Operating Conditions

- Temperature: - 20 ℃~ 40 ℃; Humidity: < 90% RH

- Applicable standard

- ISO, ANSI, DIN, JIS

- Sensors - Guide

- Carbide, sliding direction radius 40mm

- Storage and transportation environment

- Temperature: - 40 ℃~ 60 ℃; Humidity: < 90% RH

- Indication Accuracy

- 0.001µm

Introduction

The surface roughness measuring instrument is a hand-held instrument suitable for the production site environment and mobile measurement needs . It can measure the surface roughness of various machined parts. It can calculate the corresponding parameters according to the selected measurement conditions and display them on the display. All measured parameters and profile . The instrument is easy to operate, comprehensive in function, fast in measurement, stable in accuracy, easy to carry, and can measure the main parameters of new international standards. This instrument fully and strictly implements international standards.

Product Structure

main feature

● Combination structure of host, driver and sensor, mechanical and electrical integration design, easy to use, small size and light weight;

● Support Bluetooth printing and mobile APP wireless operation.

● Multiple parameters Ra, Rz, Rq, Rt, Rp, Rv, R3z, R3y, Rz (JIS), Rs, Rsk, Rsm, Rku, Rc, Ry, Rmax, Rmr.

● Luxurious instruments add RPc, Rk, Rpk, Rvk, Mr1, Mr2 and other parameters;

● Large measuring range of 160μm, luxury type 320μm ;

● 480×320 TFT color liquid crystal display, digital/graphic display; adjustable brightness, wide Viewing Angle;

● Using DSP chip for control and data processing, with fast speed and low power consumption;

● The display information is rich and intuitive, and can display all parameters and graphics;

● Compatible with ISO, DIN, ANSI, JIS multiple national standards;

● Built-in 3200mAh lithium battery and charging control circuit, high capacity, no memory effect;

● There is a remaining power indicator icon to remind the user to charge in time;

● It can display the indication of the charging process, and the operator can know the charging degree at any time ;

● The continuous working time is greater than 50 hours ;

● Large-capacity data storage, which can store 100 sets of original data and waveforms ;

● Real-time clock setting and display, convenient for data recording and storage ;

● Power-saving functions such as automatic sleep and automatic shutdown ;

● Reliable anti-motor dead circuit and software design ;

● Display measurement information, menu prompt information, error information and various prompt ;

● Ergonomic shell design, strong, compact, portable, and high reliability.

● Multilingual selection;

● Can be connected to computer and printer;

● Can print all parameters or print any parameter set by the user ;

● The calibration sample block is made of optical glass substrate, which has high precision, is not easy to be scratched, and has a long service life.

● Optional surface sensor, small hole sensor, deep groove sensor, extremely small hole sensor, measuring platform, sensor sheath, extension rod, height gauge bracket, magnetic table bracket and other accessories.

Applications

It is suitable for on-site inspection of large workpieces and production lines, as well as out-of-service inspections of inspection, measurement, commodity inspection and other departments, without causing damage to the workpiece.

The range of workpieces that can be measured: plane, outer circular surface, conical surface, inner hole, groove, curved surface, etc. ( special surfaces need to be equipped with suitable sensors for measurement).

- 1GB/T 44390-2024《Print display—Measuring method of film uniformity》

- 2GB/T 39077-2024《Test methods for detecting detrimental phase in austenitic-ferritic (duplex) stainless steels》

- 3JJF 1105-2018《Calibration Specification for Contact(Stylus)Instruments of Surface Roughness Measurement by Profile Method》

- 4JJG 2018-1989《Measuring Instruments for Surface Roughness》

- 5HB 6172-1988《General surface roughness》

- 6GB/T 42671-2023《Test method for surface roughness of carbon materials》

- 7QB/T 2693-2005《QB/T 2693-2005》

- 8GB/T 13288.2-2011《Preparation of steel substrates before application of paints and related products - Surface roughness characteristics of blast-cleaned substrates - Part 2: Method for the grading of surface profile of abrasive blast-cleaned steel - Comparator procedure》

- 9GB/T 6060.5-1988《Metal asperity comparison specimens, shot throwing (spraying), sand blasting machined surfaces (neq ISO 3632-II: 1985)》

NDT160

NDT160