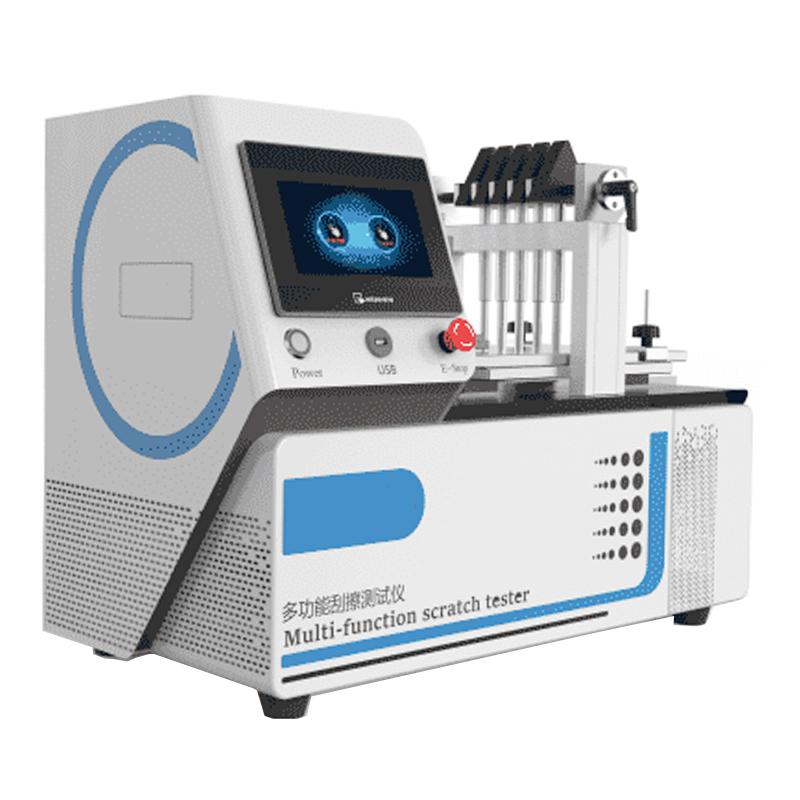

HUITAO CSI-109 Multifunctional Scratch Tester, Five Finger Scratch Tester

SEhuitao CSI-109 Multifunctional scratch TesterSPEC

huitao CSI-109 Multifunctional scratch TesterDetails

huitao CSI-109 Multifunctional scratch TesterPacking list

- SKU

- NB035896

- range of travel

- 10-200mm

- Speed range

- 10-200mm/s

- speed buffering

- 10±1mm

- Diameter of metal scraper head

- 0.5mm、0.75mm、1mm(Erichsen318)、3mm、5mm、7mm,1.4mm

- Metal scraper head material

- Tungsten Carbide uses tungsten carbide as a scraping finger to accurately detect surface wear that is damaged by unconventionally defined physical forms such as scraping, scratching, planing, etc.

- Pressurized Weight and total Weight of scraping components

- 2N, 3N, 5N, 7N, 8N, 10N, 12N, 15N, 20N (optional) The Mass error does not exceed 1%, and the customized Weight is optional

- Plastic scraping finger

- Polymethyl methacrylate (PMMA)

- diameter

- 16mm

- Film thickness

- 1mm

- Scrape the radius of the edge

- 0.5mm

- Hardness

- shore D8528

- Dimensions

- 770×550×500mm

- Weight

- 50Kg

- Power

- AC220V±10% 50Hz

Application

Actively detect the wear resistance of smooth and textured plastic trims in automotive interior and exterior trims. This instrument is suitable for various automotive interior materials, such as plastics, rubber, leather, fabrics, coating materials, non- Scratch resistance testing of coating materials and other composite materials. Actively detect the wear resistance of smooth and textured plastic trims in automotive interior and exterior trims. The instrument consists of two parts of the scratching device. The left half can be used for five-finger/plastic finger scratch test, and the right half can be used for 100-grid method Scratch test. Both share a reciprocating mobile platform. This instrument meets a variety of test standards, and can customize the motion stroke, motion speed and reciprocating motion cycle of the test platform according to customer requirements

Standards

GB/T 2918 Standard environment for condition adjustment and testing of plastic specimens GB/T 6151 General rules for color fastness tests GB/T 8424.3 Calculation of color difference for color fastness tests PV3952 Volkswagen scratch resistance test method GS97034 Surface test for automotive interior materials 97034-2, FORD FLTM BN 108-13, GMW 14698 (B method), GM 14688 (A method), GM 14688 (B method), PV 3952--3951, FORD FLTM BN 108-13, GMW 14698 (B method ), FORD BO-162-01, GMN 3943, Nissan NES M0159, etc.

Structure and composition

Automobile interior multifunctional scratch resistance Tester is suitable for all kinds of automobile interior materials scratch performance testing instrument, the instrument integrates three domestic (CN) testing standards (five-finger scratch method, 100-grid method, plastic finger scratch method). This test method is used to test the ability of surface materials to resist damage caused by scratching fingers. According to the nails or other hard objects that may come into contact with the material, scraping fingers of different materials are used to act on the surface of the sample with a certain pressure according to the specified direction, stroke, and speed, and the scraping head and the sample make relative motion, resulting in One-way, non-reciprocating linear scraping track, the scratches are kept parallel.

CSI-109

CSI-109