What properties do water-based coatings for automotive plastic parts need to test?

Plasticization of automobiles is a major development trend in today's international automobile manufacturing industry. It has the characteristics of light weight, easy plastic molding, and strong corrosion resistance of plastic. Water-based coatings are the main trend in the development of the automotive industry. They are mainly used for the decoration and protection of automotive airbag system trim components, automotive interior plastic parts, automotive exterior plastic parts, and other passenger cars and commercial vehicle plastic parts. It is a kind of environmental protection coating developed rapidly in recent years. In addition to the high strength and wear resistance of general solvent coatings, it has no pollution to the environment and has little danger of poisoning and fire. my country's testing standard for water-based coatings for automotive plastic parts is HG/T 5180-2017 "Water-based Coatings for Automotive Plastic Parts".

Suitable

HG/T 5180-2017 is applicable to the volatile organic compound (VOC) content (after deducting water) in the construction state is less than 420 g/L or the volatile organic compound (VOC) emission during the coating process is less than 35 g/㎡ Water-based coatings for automobiles are not suitable for water-based coatings for plastic parts such as lights, mirrors, wheels and logos.

Detection classification

HG/T 5180-2017 divides water-based coatings for automotive plastic parts into three types according to their uses: Type A is water-based coatings for automotive airbag system trim components; Type B is water-based coatings for automotive interior parts; Water-based coatings for exterior parts; Class C is divided into primers, intermediate paints and top coats, and top coats are further divided into natural top coats, base coats and varnishes.

Test items

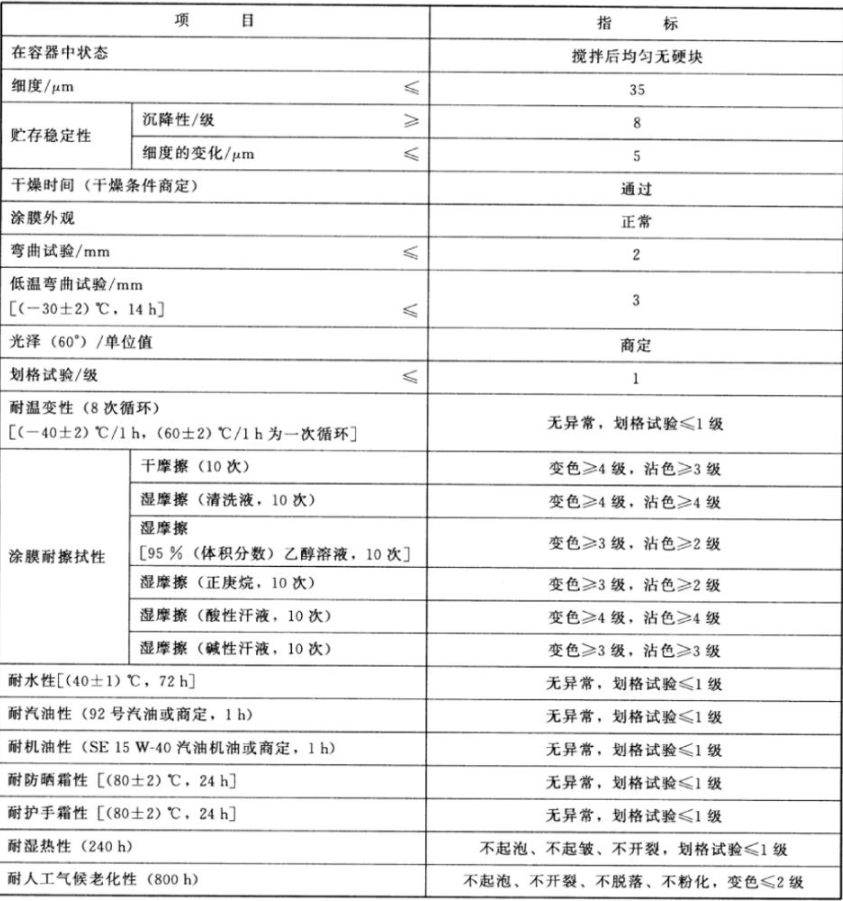

The factory inspection items of Class A products include the state in the container, fineness, drying time, appearance of the coating film, bending test, gloss, and scratch test.

The factory inspection items of Class B products include the state in the container, fineness, drying time, appearance of the coating film, bending test, impact resistance, pencil hardness, gloss, and cross-cut test.

The factory inspection items of C-type product primers and intermediate paints include the state in the container, fineness, drying time, appearance of the paint film, bending test, impact resistance, and the factory inspection items of the top coat include the state in the container, fineness, coating film Appearance, bending test, impact resistance, pencil hardness, gloss.

Sample preparation

Unless the paint supplier has other requirements for its substrate, supporting system, paint variety, number of coats, dry film thickness, etc., the sample preparation shall be carried out in accordance with the specified requirements, and the application interval and drying conditions between multiple coats shall be etc. to be agreed upon by the relevant parties. The measurement of coating film thickness shall be carried out according to the provisions of GB/T 13452.2-2008. Control the dry film thickness of the plastic template with the dry film thickness of the tinplate plate sprayed at the same time as a reference.

(Note: For items that need to be inspected quickly (such as factory inspection items, etc.), the preparation, drying and curing conditions of the coating film can be negotiated by the relevant parties.)

Class A product sample preparation factory inspection items include bending test, low temperature bending test, gloss, drying time, coating appearance, scratch test, temperature change resistance, coating resistance to wiping, water resistance, gasoline resistance, engine oil resistance, Resistance to sunscreen, hand cream, humidity and heat, and artificial weathering .

Class B product sample preparation factory inspection items include bending test, impact resistance, gloss, drying time, coating appearance, pencil hardness, cross-cut test, temperature change resistance, coating resistance to wiping, water resistance, gasoline resistance, Motor oil resistance, sunscreen resistance, hand cream resistance, heat and humidity resistance, artificial weathering resistance .

Type C product sample preparation Primer, intermediate paint factory inspection items include bending test, impact resistance, drying time, coating appearance, cross-cut test , topcoat sample preparation factory inspection items include bending test, impact resistance, gloss, drying Time, appearance of coating film, sharpness of pencil hardness, cross-cut test, resistance to temperature change, water resistance, acid resistance, alkali resistance, gasoline resistance, engine oil resistance, heat and humidity resistance, and artificial weathering resistance .

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film

-

-

-

TRUIT TR 5214 Bending Tester$ 439.00

-

-

-