Defelsko NKS thick coating probe for nonmagnetic metal substrates

SEDefelsko PRBNKS-D Thickness Gauge probeSPEC

Defelsko PRBNKS-D Thickness Gauge probeDetails

Defelsko PRBNKS-D Thickness Gauge probePacking list

- SKU

- NB015166

- Measurement principle

- Magnetic Induction

- Measurement range

- 0~13mm

- margin of error

- ±3%

- Resolution

- 0.1μm

- probe

- 6000 NKS Cabled Probe

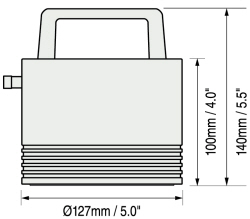

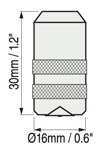

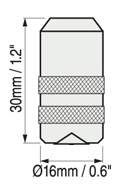

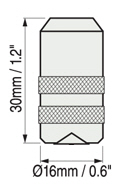

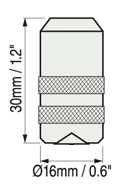

- Probe size

- Φ30mm

- Calibrated Certificate

- Yes.

- compatible model

- PosiTector

Full range of probe details

Detachable built-in probe

Detachable built-in probe

F,N,FN,FT

Suitable for one-handed operation

| Detachable built-in probe | Probe model | F、N、FN | FT | ||

| range | 0~60 mils | 0~250mils | ||

| 0~1500μm | 0~6mm/0~6000μm | ||||

| precision | + (0.05 mils + 1%) 0~2 mils + (0.1 mils + 1%) > 2 mils | + (0.5 mils + 1%) 0~100 mils + (0.5 mil + 3%) > 100 mils | |||

+ (1 um + 1%) 0~50 um + (2 um + 1%) > 50 um | + (0.01 mm + 1%) 0~2.5 mm + (0.01 mm + 3%) > 2.5 mm | ||||

| Accuracy is calculated by adding a fixed value to the percentage of readings | |||||

Split conventional probes

FS,NS,FNS,NAS,FTS

These constant-pressure, stainless steel probes are hermetically sealed and completely waterproof – ideal for underwater measurements.

| Regular | Probe model | FS、NS、FNS | NAS | FTS |

| range | 0~60 mils | 0~25 mils | 0~250 mils |

| 0~1500 um | 0~625 um | 0~6 mm/0~6000 μm | ||

| precision | + (0.05 mils + 1%) 0~2 mils + (0.1 mils + 1%) > 2 mils | + (0.02 mils + 1%) 0~4 mils + (0.1 mils + 3%) > 4 mils | + (0.5 mils + 1%) 0~100 mils + (0.5 mil + 3%) > 100 mils | |

+ (1 um + 1%) 0~50 um + (2 um + 1%) > 50 um | + (.5 um + 1%) 0~100 um + (2 um + 3%) > 100 um | + (0.01 mm + 1%) 0~2.5 mm + (0.01 mm + 3%) > 2.5 mm | ||

| Accuracy is calculated by adding a fixed value to the percentage of readings | ||||

FXS Xtreme™

Uniquely designed for applications with rough surfaces. The measuring surface of the FXS Xtreme™ probe is a zirconia toughened alumina wear surface, which is ideal for measuring rough steel surfaces.

Increases the measurement speed to 50 readings per minute, making it suitable for fast measurement of large, rough surfaces. The scan mode increases the rate of measurement to more than 100 readings per minute. (Only PosiTector Premium models have a scan mode)

Compatible with PosiTector mainframes with serial numbers greater than 700,000 and the new Positector SmartLink.

| FXS Xtreme™ | ||

| range | 0~1500 um |

| 0~60 mils | ||

| precision | + (0.05 mils + 1%) 0~2 mils + (0.1 mils + 1%) > 2 mils | |

+ (1 um + 1%) 0~50 um + (2 um + 1%) > 50 um | ||

| Accuracy is calculated by adding a fixed value to the percentage of readings | ||

Split 90° conventional probe

FRS,NRS,FNRS

Right-angle probes are suitable for measuring low headroom areas.

These constant-pressure, stainless steel probes are hermetically sealed and completely waterproof – ideal for underwater measurements

| 90° conventional type | Probe model | FRS、NRS、FNRS |

| range | 0~60 mils |

| 0~1500 um | ||

| precision | + (0.05 mils + 1%) 0~2 mils + (0.1 mils + 1%) > 2 mils | |

+ (1 um + 1%) 0~50 um + (2 um + 1%) > 50 um | ||

| Accuracy is calculated by adding a fixed value to the percentage of readings | ||

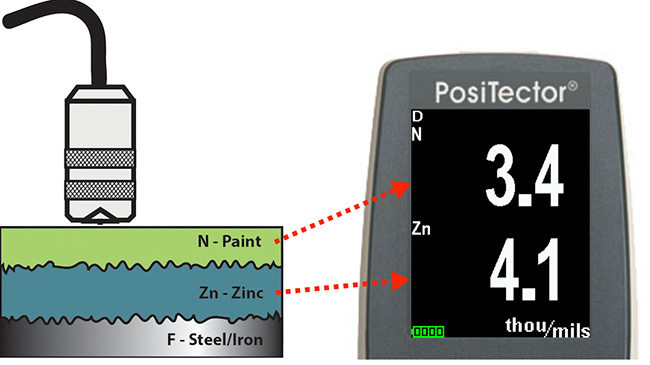

FNDS

The PosiTector 6000 FNDS probe simultaneously measures the thickness of paint and zinc layers in a composite coating system in a single readout.

Composite coating systems use a combination of two corrosion protection systems – typically painted or powder coated on galvanized steel (thermal, electrical, or zinc-sprayed metal). resultantCorrosion protection due toanySeparate protection system.

In composite mode, the positector 6000 FNDS is usedmagnetic induction(ferrous) and eddy current (non-ferrous) principles that simultaneously calculate and display individual coating and zinc layer thicknesses. The magnetic induction principle is used to measure the total thickness of the lacquer/zinc layer on a ferrous substrate, while the eddy current Thickness Gauge principle is used to measure the thickness of the paint layer on a non-ferrous zinc layer. The zinc layer thickness is calculated by subtracting the thickness of the paint layer from the total lacquer/zinc layer thickness. The schematic diagram is as follows,

When not available, the gauge is like a traditional ferrous/non-ferrous dual-function gauge (similar topositector 6000 FNS probe). It is suitable for measuring the thickness of non-magnetic coatings on steel and non-conductive coatings on non-ferrous metal substrates.

Positicctor Advanced (serial number 730000+) and color LCD are compatible with the Positicctor standard gage. A simple Thickness Gauge update is required.

| FNDS | ||||

| range | 0~60 mils/0~1500 um | ||

| Composite coating | Minimum zinc layer thickness | 0.5 mil (13 um) | ||

| Paint layer accuracy | Mils | + (0.05 mils + 1%) 0~2 mils + (0.1 mils + 1%) > 2 mils | ||

| μm | + (1 um + 1%) 0~50 um + (2 um + 1%) > 50 um | |||

| Zinc layer accuracy | Mils | + (0.1 mils + 1%) 0.5~2 mils + (0.2 mils + 1%) > 2 mils | ||

| μm | + (2 um + 1%) 13~50 um + (4 um + 1%) > 50 um | |||

| Accuracy is calculated by adding a fixed value to the percentage of readings | ||||

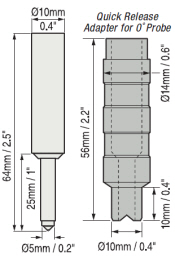

Split 0° probe

Split 0° probe

F0S,N0S

With a minimal measuring tip and very good thin-film measurement accuracy, this probe is suitable for measuring small parts, hard-to-reach areas or near edges.

The straight F0S and N0S miniature probes have a quick-release adapter that allows them to be targeted at a constant pressure on small, flat or curved parts. This adapter is designed on a spring, if you don't need a sleeve, simply unplug it from the probe.

| 0° miniature probe | Probe model | F0S | N0S |

| range | 0~45 mils | 0~25 mils |

| 0~1150 um | 0~625 um | ||

| precision | + (0.02 mils + 1%) 0~4 mils + (0.1 mils + 3%) > 4 mils | ||

+ (0.5 um + 1%) 0~100 um + (2 um + 3%) > 100 um | |||

| Accuracy is calculated by adding a fixed value to the percentage of readings | |||

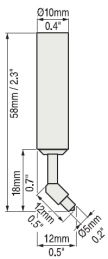

Split 45° miniature probe

F45S,N45S

With a minimal measuring tip and very good thin-film measurement accuracy, this probe is suitable for measuring small parts, hard-to-reach areas or near edges.

| 45° miniature probe | Probe model | F45S | N45S |

| range | 0~45 mils | 0~25 mils |

| 0~1150 um | 0~625 um | ||

| precision | + (0.02 mils + 1%) 0~4 mils + (0.1 mils + 3%) > 4 mils | ||

+ (0.5 um + 1%) 0~100 um + (2 um + 3%) > 100 um | |||

| Accuracy is calculated by adding a fixed value to the percentage of readings | |||

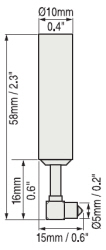

Split 90° miniature probe

F90S,N90S

Right-angle probes are suitable for measuring low headroom areas.

With a minimal measuring tip and very good thin-film measurement accuracy, this probe is suitable for measuring small parts, hard-to-reach areas or near edges.

| 90° miniature probe | Probe model | F90S | N90S |

| range | 0~45 mils | 0~25 mils |

| 0~1150 um | 0~625 um | ||

| precision | + (0.02 mils + 1%) 0~4 mils + (0.1 mils + 3%) > 4 mils | ||

+ (0.5 um + 1%) 0~100 um + (2 um + 3%) > 100 um | |||

| Accuracy is calculated by adding a fixed value to the percentage of readings | |||

Wide-range probes

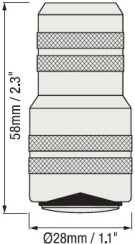

FT,FTS,FNTS,FKS,NKS

Suitable for thick coatings such as epoxy resin, rubber, cement, intumescent fire retardant coatings, etc.

| Large-scale type | Probe model | FT,FTS,FNTS | FKS,NKS | ||

|  |  | range | 0~250 mils | 0~500 mils |

| 0~6 mm/0~6000 μm | 0~13 mm/0~500 mils | ||||

| precision | + (0.5 mils + 1%) 0~100 mils + (0.5 mil + 3%) > 100 mils | + (1 mils + 3%) + (0.02 mm + 3%) | |||

+ (0.01 mm + 1%) 0~2.5 mm + (0.01 mm + 3%) > 2.5 mm | |||||

| FT | FTS | FNTS,FKS,NKS | Accuracy is calculated by adding a fixed value to the percentage of readings | ||

FHXS Xtreme

FHXS Xtreme

Measure non-conductive coatings on steel substrates

The FHXs Xtreme probe comes with alumina, abrasion-resistant contact surfaces and braided cables for use on hot or rough surfaces. Hot surface temperatures can be as high as 250°C (500°F).

Compatible with PosiTector mainframes with serial numbers greater than 700,000 and the new Positector SmartLink.

| FHXS Xtreme | ||

| range | 0~400 mils |

| 0~10000 um | ||

| precision | + (0.1 mils + 3%) | |

+ (2 um + 3%) | ||

| Accuracy is calculated by adding a fixed value to the percentage of readings | ||

FLS

Suitable for measuring intumescent varnish and other thick protective coatings on steel.

● Measure thickness up to 38mm (1.5 inches)

● Braided stainless steel cable - torsion-resistant, abrasion-resistant, shear-resistant

● Includes hard case and 19 mm (750 mil) spacer

Compatible with PosiTector mainframes with serial numbers greater than 700,000 and the new Positector SmartLink.

| FLS | ||

| range | 0~38 mm |

| 0~1.5inch | ||

| precision | + (0.01 in. + 3%) | |

| + (0.2 mm + 3%) | ||

| Minimum surface area | 3.25 x 3.25 inches (83 x 83 mm) | |

| Minimum substrate thickness | 0.1inch(2.5 mm) | |

| Accuracy is calculated by adding a fixed value to the percentage of readings | ||

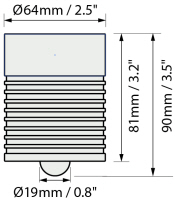

FNGS

Suitable for measuring very thick coatings on all metals. It is particularly suitable for measuring hull coatings and thick intumescent coatings.

● Measure thicknesses up to 63.5 mm (2.5 inches)

● Measure the thickness of non-conductive coatings on magnetic and non-magnetic metal substrates.

● Braided stainless steel cable - torsion-resistant, abrasion-resistant, shear-resistant

● Long-lasting, low-wear probe contact for easy scanning of large areas.

● Includes a handle for easy one-handed operation

● Includes a set of traceable coating thickness standards

● Instruction cards are included

Compatible with PosiTector mainframes with serial numbers greater than 700,000 and the new Positector SmartLink.

| FLS | ||

Probe weight: 0.8kg | range | 0~63.5 mm |

| 0~2.5inch | ||

| precision | + (0.01" + 3%) | |

| + (0.2 mm + 3%) | ||

| Minimum surface area | 10 x 10 inches (254x254 mm) | |

| Minimum substrate thickness | 0.2inch(2.5 mm) | |

| Accuracy is calculated by adding a fixed value to the percentage of readings | ||

Probe Purchase Chart

F – Ironsubstrate(Steel & Cast Iron)

N - NonIronmetalsubstrate(Aluminum, copper, titanium, etc.)

FN – All metal substrates – automatic identification of substrates

| Probe model | substrate | Probe type | Measuring range |

| F | Iron | Movable built-in | 0~60 mils (0~1500 um) |

| FS | Iron | Conventional cables | 0~60 mils (0~1500 um) |

| FXS Xtreme™ | Iron | routinecable | 0~60 mils (0~1500 um) |

| FRS | Iron | 90° conventional cable | 0~60 mils (0~1500 um) |

| F0S | Iron | 0° miniature probe | 0~45 mils (0~1150 um) |

| F45S | Iron | 45° miniature probe | 0~45 mils (0~1150 um) |

| F90S | Iron | 90° miniature probe | 0~45 mils (0~1150 um) |

| FT | Iron | Movable built-in | 0~250 mils (0~6 mm) |

| FTS | Iron | A wide range of cables | 0~250 mils (0~6 mm) |

| FKS | Iron | A wide range of cables | 0~500 mils (0~13 mm) |

| FHXS Xtreme™ | Iron | A wide range of cables | 0~400 mils (0~10000 um) |

| FLS | Iron | A wide range of cables | 0~1.5 inches (0~38 mm) |

| N | notIron | Movable built-in | 0~60 mils (0~1500 um) |

| NS | notIron | Conventional cables | 0~60 mils (0~1500 um) |

| NRS | notIron | 90° conventional cable | 0~60 mils (0~1500 um) |

| NAS | notIron | Conventional cables | 0~25 mils (0~625 um) |

| N0S | notIron | 0° miniature probe | 0~25 mils (0~625 um) |

| N45S | notIron | 45° miniature probe | 0~25 mils (0~625 um) |

| N90S | notIron | 90° miniature probe | 0~25 mils (0~625 um) |

| NKS | notIron | A wide range of cables | 0~500 mils (0~13 mm) |

| FN | Iron/notIron | Movable built-in | 0~60 mils (0~1500 um) |

| FNS | Iron/notIron | Conventional cables | 0~60 mils (0~1500 um) |

| FNRS | Iron/notIron | 90° conventional cable | 0~60 mils (0~1500 um) |

| FNDS (duplex) | Iron/notIron | Conventional cables | 0~60 mils (0~1500 um) |

| FNTS | Iron/notIron | A wide range of cables | 0~250 mils (0~6 mm) |

| FNGS | Iron/notIron | A wide range of cables | 0~2.5 inches (0~63.5 mm) |

- 1ISO 《Non-magnetic metallic coatings on metallic and non-metallic basis materials — Measurement of coating thickness — Phase-sensitive eddycurrent method》

- 2GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 3JB/T 13939-2020《Nondestructive testing instruments.Eddy current thickness gauge》

- 4QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 5 901-2021《Technical specification for the application of fireproof coatings for tunnels》

- 6 10254-2022《Green building materials evaluation fire retardant coating》

- 7GB 15442.1-1995《Classification and test methods for fire retardancy of finishing fire retardant paints--Classification for fire retardancy》

- 8GB 28375-2012《Fireproof coatings for concrete structure》

- 9GB 12441-2018《Finishing fire resistant coating》

- 10GB 14907-2018《Fire resistive coating for steel structure》

PRBNKS-D

PRBNKS-D